Automatic check and early warning method and system based on infrared imaging temperature measurement for electric power equipment

An infrared imaging and power equipment technology, which is applied to alarms, measuring devices, instruments, etc., can solve problems such as failure to automatically analyze and diagnose power equipment faults, inability to monitor the operating status of power equipment in real time, and being affected by environmental climate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

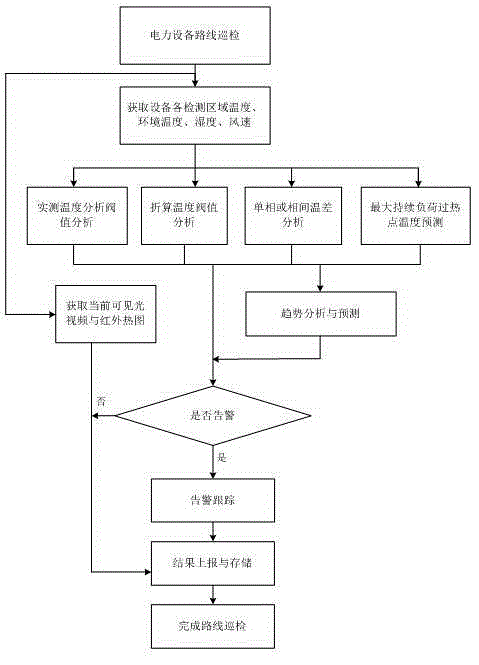

[0015] Example 1. The automatic inspection and early warning method of the present invention comprises the following steps:

[0016] 1) Obtain the measured temperature and ambient temperature, humidity, and wind speed of each detection area of the power equipment; at the same time, obtain the current visible light video and infrared heat map of each detection area of the power equipment;

[0017] 2) Through the actual temperature analysis threshold analysis, converted temperature threshold analysis, single-phase or phase-to-phase temperature difference analysis, maximum continuous load hot spot temperature prediction, trend analysis and prediction of the operating status of power equipment for a period of time in the future;

[0018] 3) According to the predicted value and combined with the alarm threshold, an audible and visual early warning is performed.

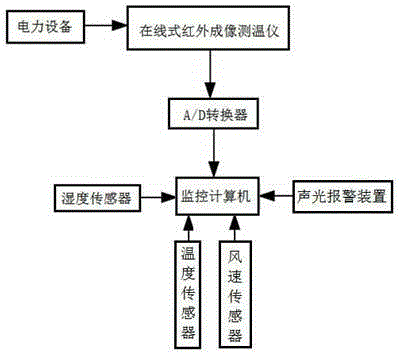

[0019] The power equipment automatic inspection and early warning system of the present invention, such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com