Roller way safe operation monitoring method and device for roller way kiln

A technology of safe operation and roller table, which is applied in the direction of furnace, furnace type, lighting and heating equipment, etc., and can solve problems such as the inability to detect the operation status of the roller and intelligently record the roller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

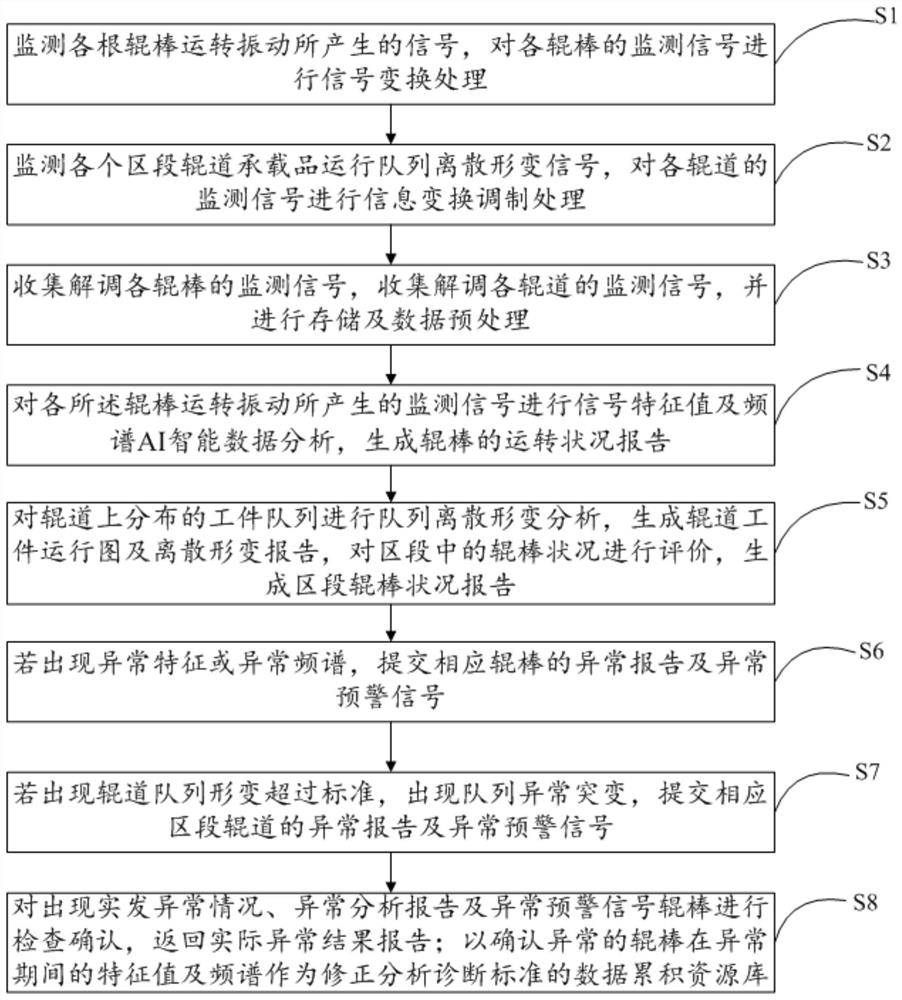

[0033] Such as figure 1 As shown, Embodiment 1 of the present invention provides a roller table safety operation monitoring method for a roller table kiln, comprising the following steps:

[0034] S1. Monitor the signals generated by the running vibration of each roller, and perform signal conversion and modulation processing on the monitoring signals of each roller;

[0035] S2. Monitor the discrete deformation signals of the running queues of the roller table loads in each section, and perform information conversion and modulation processing on the monitoring signals of each roller table;

[0036] S3. Collect and demodulate the monitoring signals of each roller bar, collect and demodulate the monitoring signals of each roller table, and perform storage and data preprocessing;

[0037] S4. Analyze the signal characteristic value and frequency spectrum AI intelligent data analysis on the monitoring signals generated by the operation vibration of each of the rollers, and gener...

Embodiment 2

[0096] Embodiment 2 of the present invention provides a roller table safety operation monitoring device for a roller table kiln, including a processor and a memory, and a computer program is stored on the memory, and when the computer program is executed by the processor, the The monitoring method for roller table safety operation provided in embodiment 1 is used for roller table kilns.

[0097] The roller table safe operation monitoring device for the roller table kiln provided by the embodiment of the present invention is used to realize the roller table safe operation monitoring method for the roller table kiln, therefore, the roller table safe operation for the roller table kiln The technical effect of the monitoring method is also possessed by the roller table safety operation monitoring device used in the roller table kiln, and will not be repeated here.

Embodiment 3

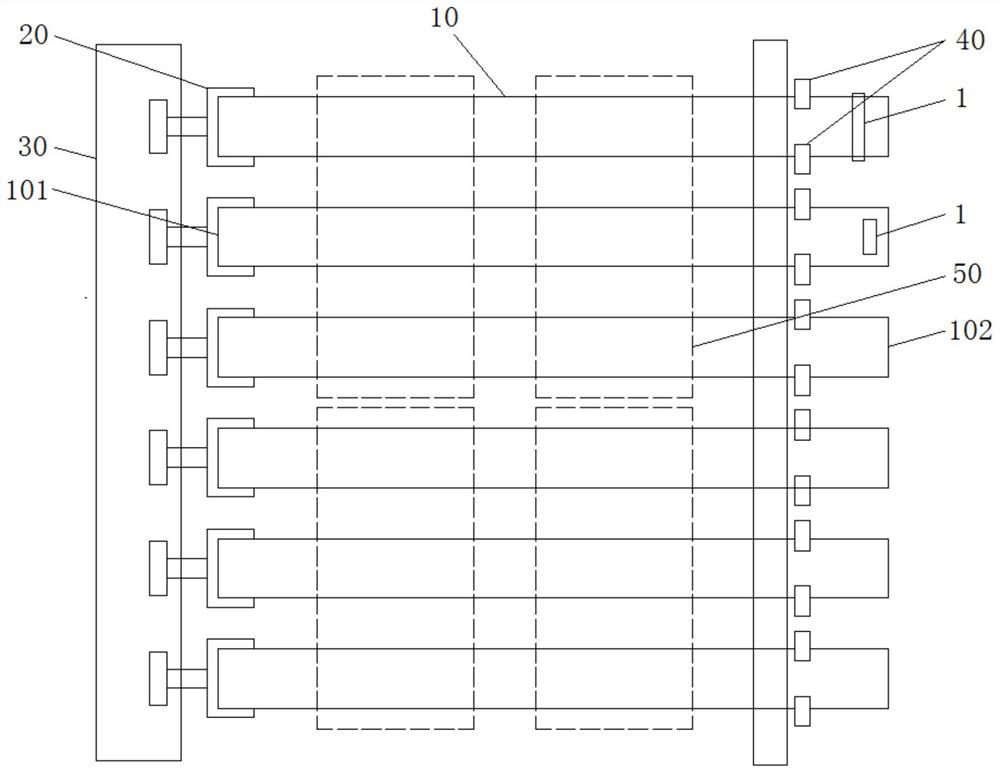

[0099] Such as figure 2 As shown, Embodiment 3 of the present invention provides a roller table safety operation monitoring system for a roller table kiln, including the roller table safety operation monitoring device for a roller table furnace provided in Embodiment 2, and also includes a detector , signal conversion and external transmission device and regional information collection remote transmission device;

[0100] Each roller of the roller kiln is equipped with the detector, the signal conversion and external transmission device is electrically connected, and the signal conversion and external transmission device is wired or wireless to the regional information collection remote transmission device connection, the remote transmission device for collecting regional information is wired or wirelessly connected to the roller table safety operation monitoring device for the roller table kiln.

[0101] First, the basic concepts related to the roller kiln are introduced: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com