Aluminum oxide and barium sulfate composite membrane for lithium ion battery and preparation method thereof

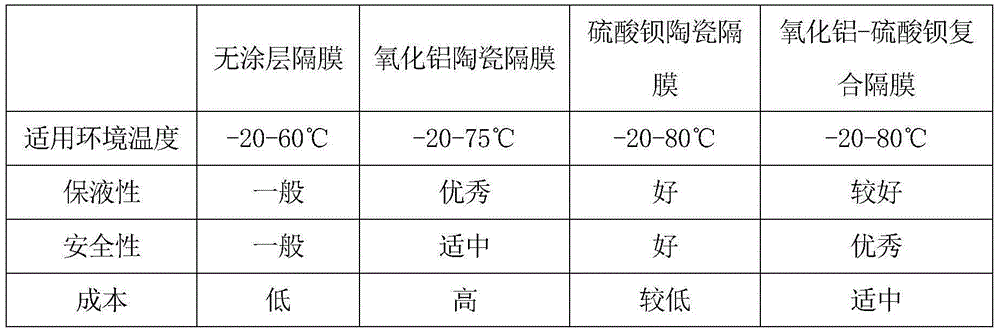

A technology for lithium-ion batteries and composite diaphragms, applied in the field of aluminum oxide-barium sulfate composite diaphragms for lithium-ion batteries and its preparation, can solve the problems of poor thermal stability and large resistance of the diaphragm, and achieve low cost, simple preparation, and low shrinkage rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of aluminum oxide-barium sulfate composite diaphragm for lithium ion battery, comprises base film and is coated on one side of base film successively and is the aluminum oxide slurry layer of thickness 1 μ m and the barium sulfate slurry layer that thickness is 8 μ m; Wherein aluminum oxide The slurry layer includes the following components in parts by weight: 100 parts of alumina powder of nanoscale particles, 3 parts of binder polyvinylidene fluoride, 0.2 parts of carboxylate surfactant, organic solvent N,N- 200 parts of dimethylformamide; wherein the barium sulfate slurry layer includes the following components in parts by weight: 100 parts of aluminum oxide powder of nanoscale particles, 3 parts of binder polytetrafluoroethylene, carboxylate surface 0.2 parts of active agent, 200 parts of organic solvent N,N-dimethylformamide, wherein the base film is 16 parts by weight of polyethylene.

[0023] The manufacture method of aluminum oxide-barium sulfate composit...

Embodiment 2

[0030] A kind of aluminum oxide-barium sulfate composite diaphragm for lithium-ion battery, comprises base film and is coated on the aluminum oxide slurry layer of thickness 8 μ m and the barium sulfate slurry layer of thickness 1 μ m that are coated on both sides of base film successively; Wherein aluminum oxide The slurry layer includes the following components in parts by weight: 100 parts of alumina powder of nanoscale particles, 10 parts of binder polyimide and polysulfone, 1 part of sulfonate surfactant, organic solvent 1000 parts of dimethylacetamide; wherein the barium sulfate slurry layer includes the following components in parts by weight: 100 parts of alumina powder of nanoscale particles, 10 parts of binder polyimide, phosphate ester salt type surface 1 part of active agent, 1000 parts of organic solvent butyrolactone, wherein the base film includes 30 parts by weight of polyethylene;

[0031] The manufacture method of aluminum oxide-barium sulfate composite separ...

Embodiment 3

[0038] A kind of aluminum oxide-barium sulfate composite diaphragm for lithium-ion battery, comprises base film and the aluminum oxide slurry layer that is 4 μ m in thickness and the barium sulfate slurry layer that thickness is 4 μ m and is coated on both sides of base film successively, wherein aluminum oxide The slurry layer includes the following components in parts by weight: 100 parts of alumina powder of nanoscale particles, 6 parts of binder acrylonitrile polymer, 0.6 part of amine salt type surfactant, 600 parts of organic solvent butyrolactone wherein the barium sulfate slurry layer includes the following components in parts by weight: 100 parts of alumina powder of nanoscale particles, 6 parts of binder polyvinylidene fluoride copolymer, 0.4 parts of phosphate ester salt type surfactant , 600 parts of butyrolactone, wherein the polyethylene of 24 parts by weight of the base film;

[0039] The manufacture method of aluminum oxide-barium sulfate composite separator fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap