A comprehensive mixing treatment equipment for sludge sedimentation tank

A technology for sludge sedimentation and treatment equipment, which is applied in water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc. It can solve the problem of lack of anti-falling device, poor fixing effect, retractable mixer Inconvenient and other problems, to achieve the effect of improving labor efficiency, convenient fixing, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

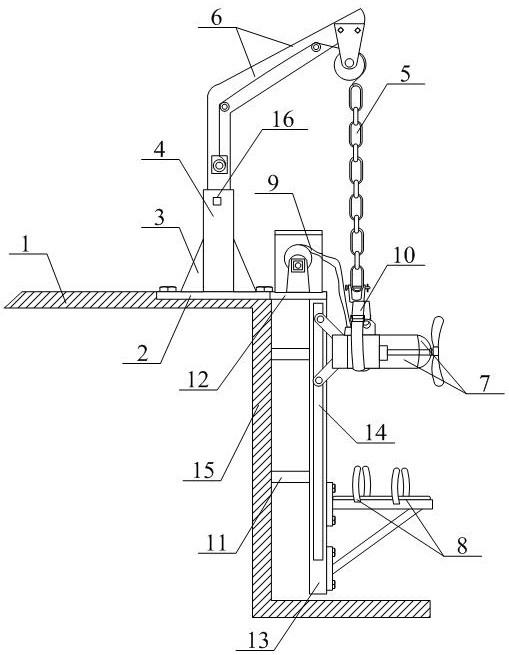

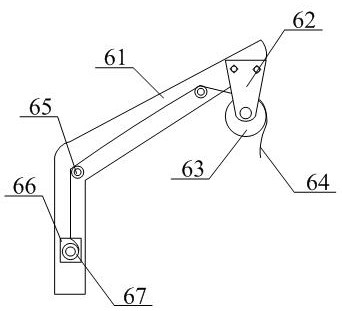

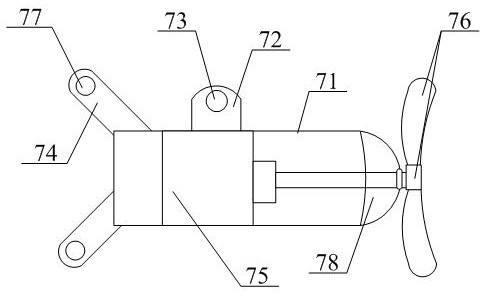

[0045] as attached figure 1 to attach Image 6 shown

[0046] The present invention provides a comprehensive mixing treatment equipment for sludge settling tank, which includes foundation surface 1, pre-embedded steel plate 2, hanger seat 3, hanger support column 4, stainless steel hanging chain 5, electric traction lifting hanger device 6, which is convenient for fixing the mixer Structure 7, stirring fixed limit seat structure 8, cable storage box structure 9, anti-drop lock structure 10, cross brace 11, connecting plate 12, support guide rod 13, chute 14, sludge sedimentation tank wall 15 and the control switch 16, the said pre-embedded steel plate 2 is bolted to the right side of the upper surface of the foundation surface 1; The lower surface of the hanger seat 3 is welded on the upper surface of the embedded steel plate 2; the hanger support column 4 is welded at the middle position of the upper surface of the embedded steel plate 2; one end of the stainless steel lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com