Binding post connection structure of grounding leading line

A technology of grounding lead wires and terminals, which is applied in connection, conductive connection, clamping/spring connection, etc. It can solve the problems of difficult connection, inconvenient test work, and inability to disassemble the terminal, so as to eliminate potential safety hazards and facilitate test work. , the effect of fast and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

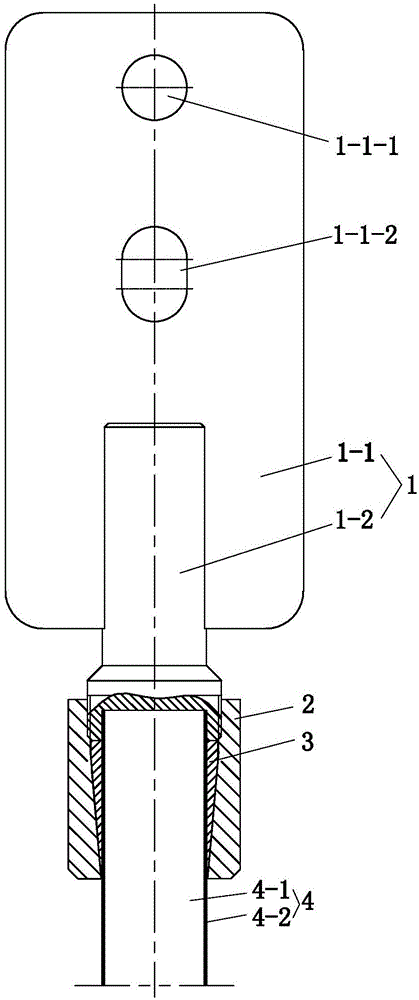

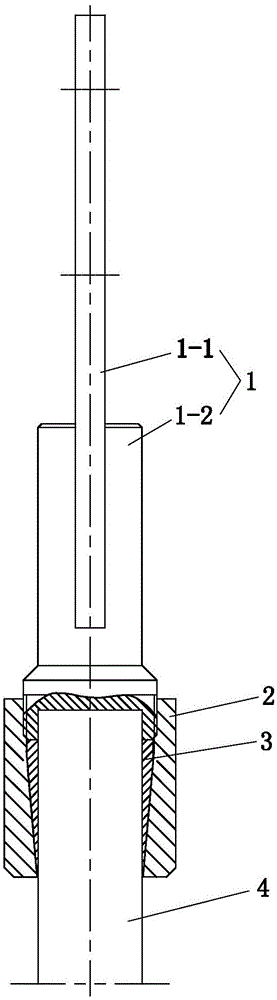

[0016] See Figure 1 to Figure 6 , the present embodiment has lead-in wire 4 and connection terminal 1, lead-in wire 4 is made up of steel mandrel 4-1 and stainless steel sheath 4-2 that tightly wraps its periphery. The terminal 1 is composed of an upper steel rectangular plate 1-1 and a lower steel cylinder 1-2. The steel cylinder 1-2 is stepped, thin at the top and thick at the bottom. A central hole 1-2-1 is provided on the bottom surface of the steel cylinder 1-2. The steel rectangular plate 1-1 of the connecting terminal 1 and the steel The cylinder 1-2 is integral, that is, formed by one-time machining.

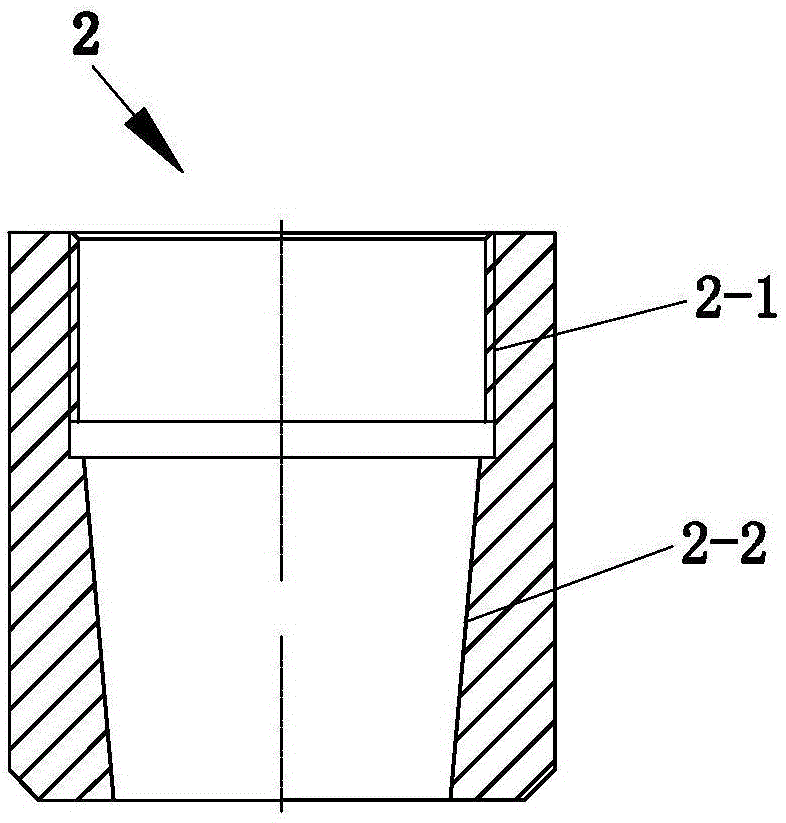

[0017] The terminal 1 is set on the lead wire 4 by using the central hole 1-2-1. The lower part of the steel cylinder 1-2 is provided with an external thread, and the lead wire 4 is covered with a nut 2. The upper part of the inner hole of the nut 2 is 2- 1 is provided with an internal thread, the bottom 2-2 of the inner hole of the nut has a taper, the nut 2 is threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com