Connector, contact member thereof and lock sleeve of contact member

A technology of contacting parts and locking sleeves, which is applied to the parts, connections, electrical components and other directions of the connecting device, can solve the problems of increased use cost, waste, and the locking sleeve cannot be removed from the optical fiber, etc., and achieves maintenance and replacement of the lock. The effect of tight sleeve is convenient, the use cost is reduced, and the separation is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

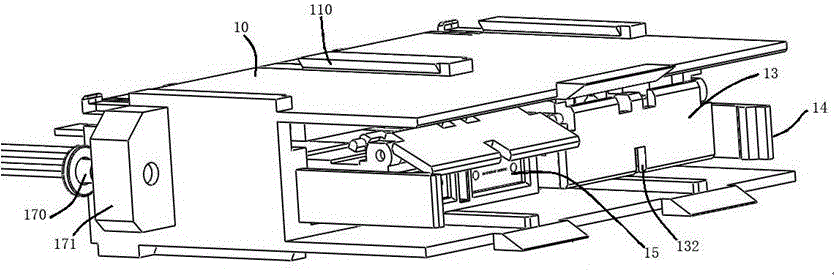

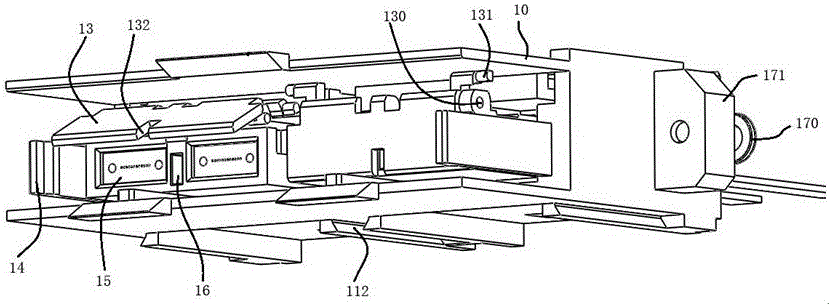

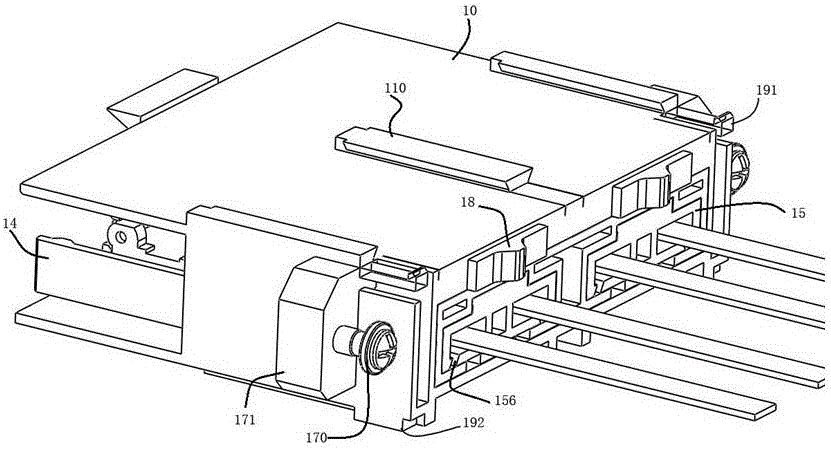

[0026] Embodiment 1 of the connector of the present invention: the connector in this embodiment is a socket connector, such as Figure 1-5 As shown, it includes a housing 10 and a contact member 15 arranged in the housing 10. The housing 10 is a rectangular housing, and two installation structures for installing the contact member 15 are arranged side by side inside the housing 10. The contact member 15 is installed on the Inside the housing 10 and extending in the front and rear directions; the left and right sides of the housing 10 are provided with a connecting structure for fixed connection with the socket connector mounting plate, the connecting structure includes connecting ears 171 and connecting screws 170 mounted on the connecting ears 171 , the rear side of the connecting ear 171 is used to fit the board surface of the socket connector mounting plate and is locked and fixed by the connecting screw 170; The position-limiting elastic hook 14 extends in the front-rear d...

Embodiment 2

[0031] Embodiment 2 of the connector of the present invention: the connector in this embodiment is a plug connector, such as Figure 6-9As shown, it includes a housing 20 and a contact member 25 arranged in the housing 20. The housing 20 is a rectangular housing, and four installation structures for installing the contact member 25 are arranged side by side inside the housing 20. The contact member 25 is installed on Inside the housing 20 and extending in the front and back directions; the left and right sides of the housing 20 are provided with floating connection structures for floating connection with the plug connector mounting plate. In this embodiment, the floating connection structures include The floating connecting ear 271 and the floating connecting piece used to connect the floating connecting ear 271 and the plug connector mounting plate. Wherein, the floating connection ear 271 is an ear plate that hangs outwards from the left and right side walls of the housing 2...

Embodiment 3

[0037] Embodiment 3 of the connector of the present invention: the difference from Embodiment 1 is that the lateral channel is arranged on the horizontal side wall and is a wave groove bent in the left and right directions.

[0038] Embodiment 4 of the connector of the present invention: the difference from Embodiment 1 is that the lateral channel is arranged on the vertical side wall and is a wave groove bent in the up and down direction, and the wave groove is arranged on the vertical side wall the middle position.

[0039] Embodiment 5 of the connector of the present invention: the difference from Embodiment 1 is that the locking sleeve is cylindrical with a central channel, and the outer peripheral surface of the cylindrical sleeve is provided with a lock with an adapter socket. The locking clips are tightly connected, and the side phase channel is an opening arranged on the circumferential direction of the cylindrical sleeve body.

[0040] The embodiment of the contact p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com