Multi-core high voltage sealed connector

A technology of high-pressure sealing and connectors, which is applied in the direction of connection, parts of connection devices, electrical components, etc., can solve the problems of difficult to meet the requirements of new technologies, high-voltage connectors do not have airtightness, low airtightness, etc., and achieve structural Novelty, wide application value, effect of improving sealing performance and high pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The multi-core high-pressure sealed connector of the present invention will be further described in detail below with reference to the drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

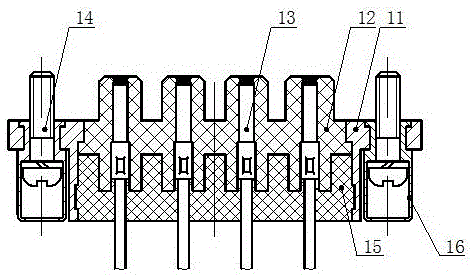

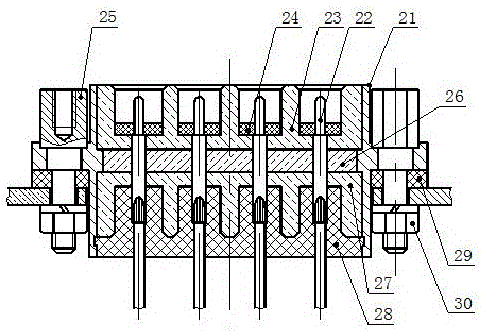

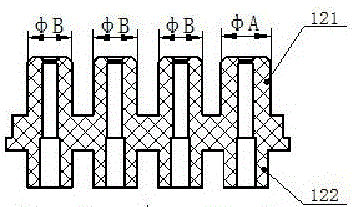

[0019] The multi-core high-pressure sealed connector provided by the present invention is composed of a plug and a socket, the plug is a free end, and the socket is fixedly installed on the mounting panel of the cavity of the sealing system. The plug is composed of a shell 11, a base 12, a socket fitting 13, a locking screw 14, epoxy glue 15, a sleeve 16 and the like. The butt joint of the base of the plug is designed as four boss cylinders 121, one of which is inconsistent with the radial dimension of the other three, which can achieve the purpose of preventing mis-insertion. In this embodiment, the rightmost boss cylinder 121 is slightly large, the other th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com