Stripping forcing system for separation and stripping electric connector on launch vehicle

A technology for electrical connectors and launch vehicles, which is applied in the direction of connection/disconnection of connecting devices, and can solve the problems of separation and disconnection of electrical connectors and failure of automatic detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

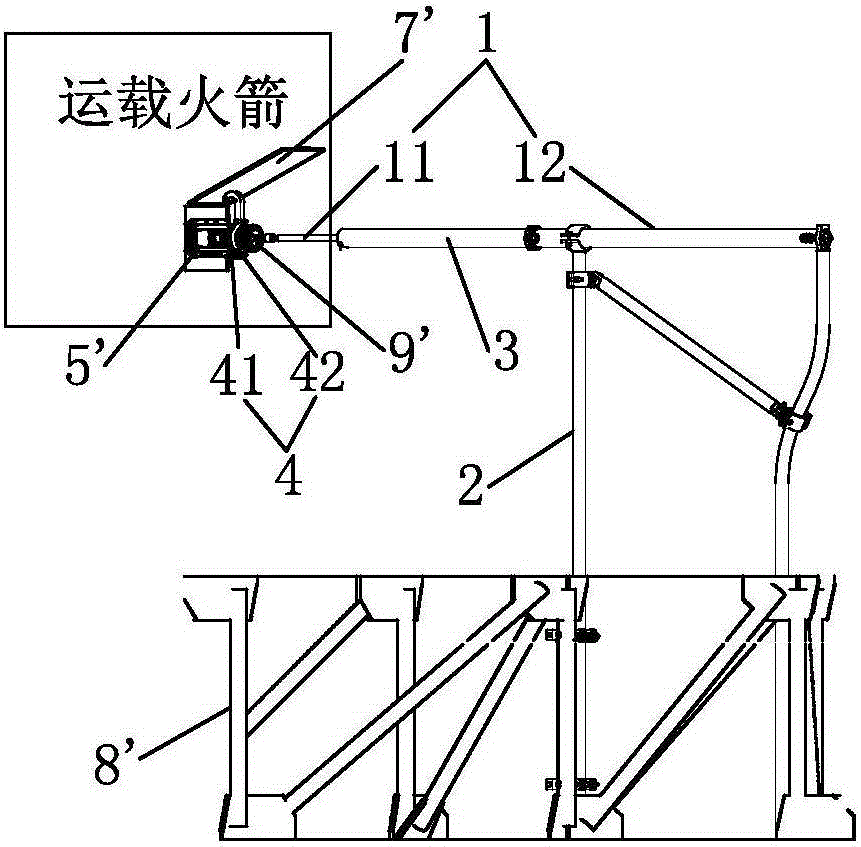

[0021] Such as figure 1 As shown, embodiment 1 of the strong release system for the separation and separation of the launch vehicle electrical connector of the present invention includes a gas distribution box, a cylinder 1, and a locking sleeve 3, and the locking sleeve 3 and the cylinder 1 are arranged horizontally, and the cylinder 1 includes a cylinder barrel 12 and the piston rod 11 arranged in the cylinder 12, the axis of the piston rod 11 coincides with the axis of the cylinder 12, and the gas distribution box is used to supply air to the cylinder 1, and the gas distribution box is not shown.

[0022] The locking sleeve 3 is located on one side of the cylinder 12 and one end of the locking sleeve 3 is fixedly connected to one end of the cylinder 12, the axis of the locking sleeve 3 coincides with the axis of the cylinder 12, and the locking sleeve 3 is set Outside the piston rod 11, that is, one end of the piston rod 11 passes through and extends out of the locking slee...

Embodiment 2

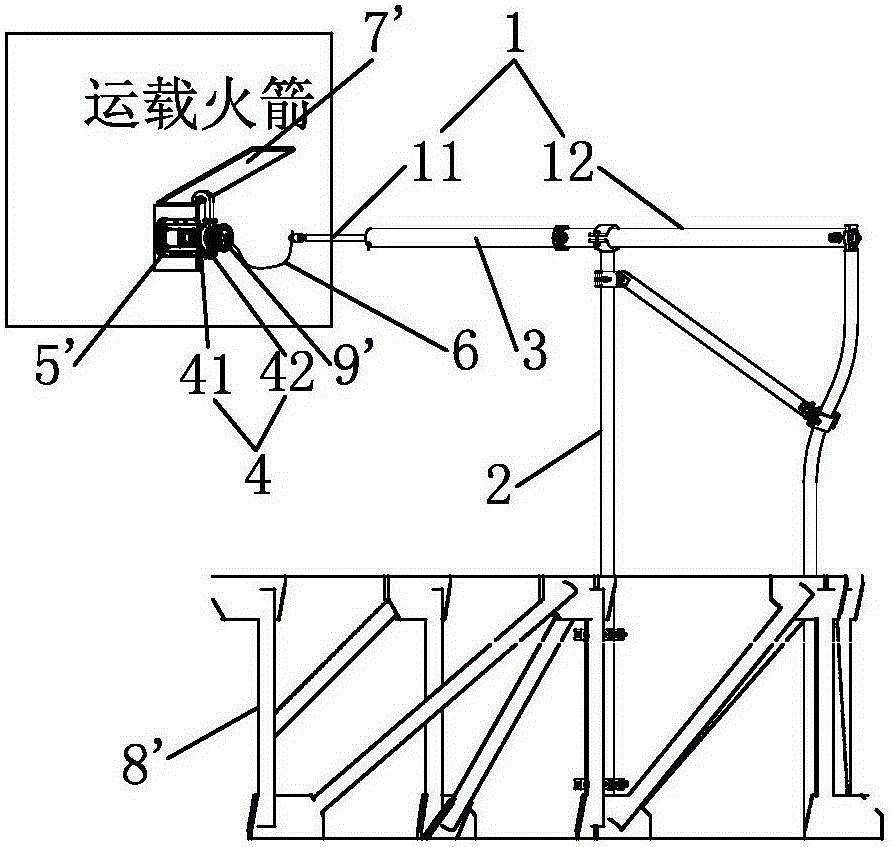

[0030] Such as figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 of the release system of the carrier rocket separation and release electrical connector of the present invention is that it also includes a steel wire 6, the piston rod 11 is connected with the locking and separating mechanism 9' through the steel wire 6, and one end of the steel wire 6 It is fixedly connected with the locking and separating mechanism 9 ′, and the other end of the steel wire 6 is fixedly connected with the piston rod 11 . The cylinder 1 pulls the steel wire 6, and the steel wire pulls the locking and separating mechanism 9' of the detached electrical connector 5' to unlock, so that the detached and detached electrical connector 5' is separated from the launch vehicle, and the steel wire 6 is used to realize the flexible connection. It can adapt to the shaking of the rocket body of the launch vehicle, that is, when the rocket body of the launch vehicle shakes, the invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com