Photovoltaic support with guide rails

A photovoltaic support and guide rail technology, which is applied in the support structure of photovoltaic modules, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of time-consuming and laborious maintenance or replacement of photovoltaic modules, and achieve the goal of increasing the laying area, increasing the number of laying, and improving installation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

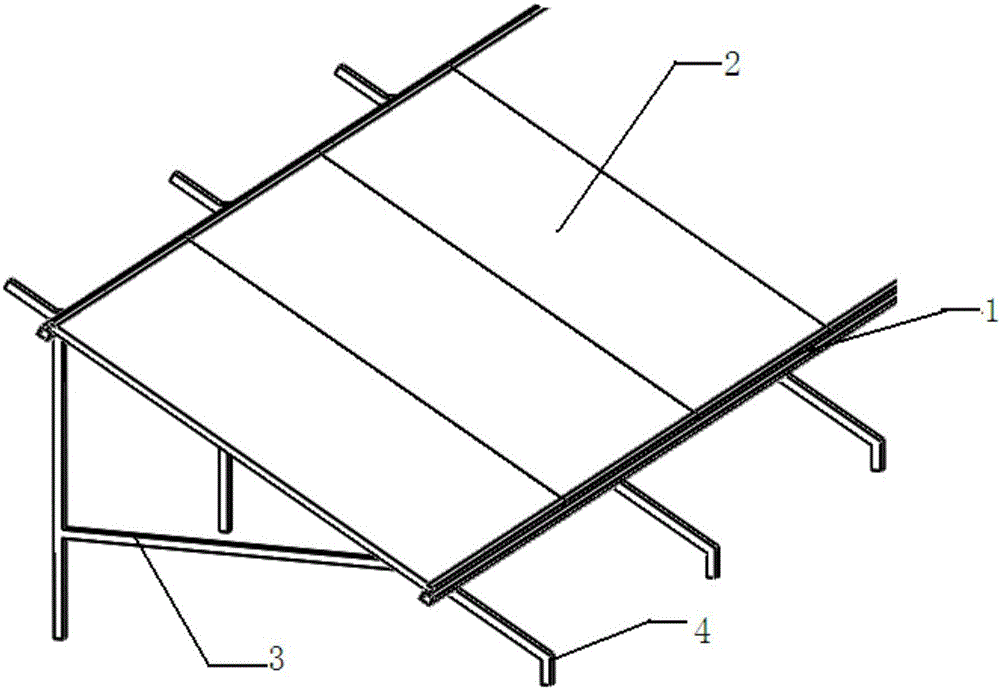

[0016] Embodiment 1: In this embodiment, a photovoltaic support with guide rails, its structure schematic diagram is as follows figure 1 As shown, a support frame 3, a support beam 4 and a guide rail device 1 are included. The support beam 4 is arranged above the support frame 3 , and the guide rail device 1 is symmetrically arranged on the support frame 3 .

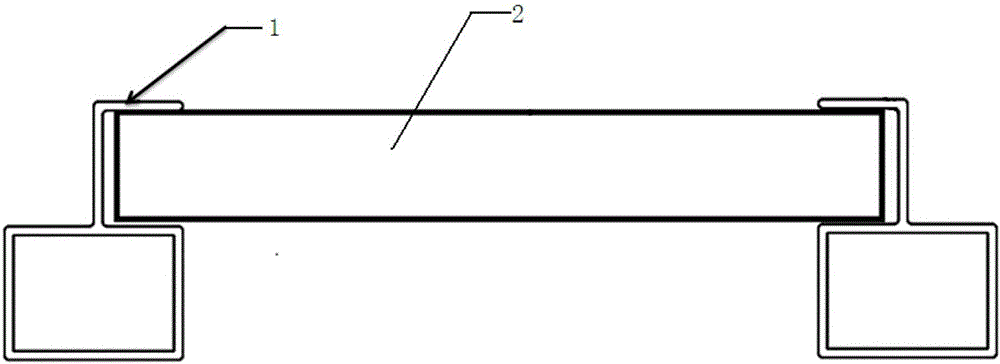

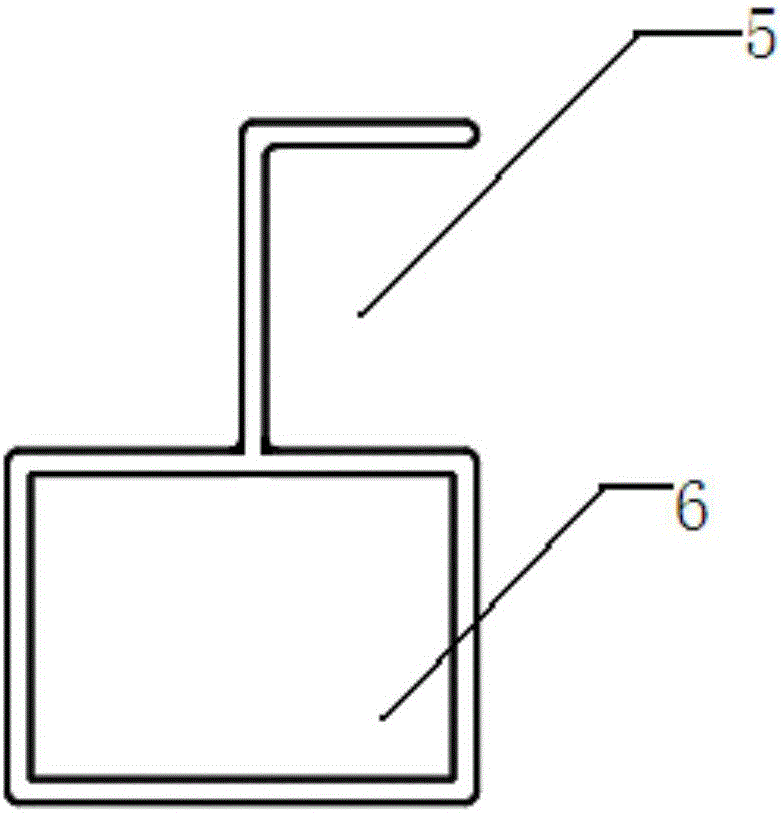

[0017] The material of the rail device 1 is aluminum, including a slot 5, the slot 5 is a right-angle slot, and its structural diagram is as follows: image 3 As shown, the inner surface is a smooth surface, the opening height of the slot 5 is matched with the thickness of the photovoltaic panel 2 to be installed, and the openings of the slots 5 of the two guide rail devices 1 are oppositely arranged. The photovoltaic panel 2 can slide directly in the slot 5 during installation. Since the height of the slot 5 corresponds to the thickness of the photovoltaic panel 2, there is no need to add additional fixing devices, and...

Embodiment 2

[0020] Embodiment 2: A photovoltaic support with guide rail provided in this embodiment, its structure and method of installation and use are basically the same as in Embodiment 1, the difference is: the structural diagram of the guide rail device 1 is as follows Figure 4 As shown, the base 6 and the slotting device are not integrally formed, and the upper bottom surface of the base 6 is provided with a fixing groove that matches the vertical wall of the slotting device, and the vertical wall of the slotting device is fixed on the fixing groove , realize the adjustment of the opening height of the embedded groove 5, and adapt to photovoltaic panels 2 of various thicknesses.

Embodiment 3

[0021] Embodiment 3: A photovoltaic support with guide rail provided in this embodiment, its structure and method of installation and use are basically the same as in Embodiment 1, the difference is: the schematic diagram of the structure of the guide rail device 1 is as follows Figure 5 As shown, the slot 5 is an arc slot, and the height of the opening of the arc slot corresponds to the thickness of the photovoltaic panel 2. Therefore, the photovoltaic panel 2 can slide in the arc slot, and the arc slot The contact area between the embedding groove and the photovoltaic panel 2 is small, which makes the photovoltaic panel easier to slide and easy to install.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com