Cartridge, and teat cup

A teat cup and sleeve technology, applied in the field of teat cups, can solve the problems of difficulty in connecting the inner sleeve of the teat cup and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

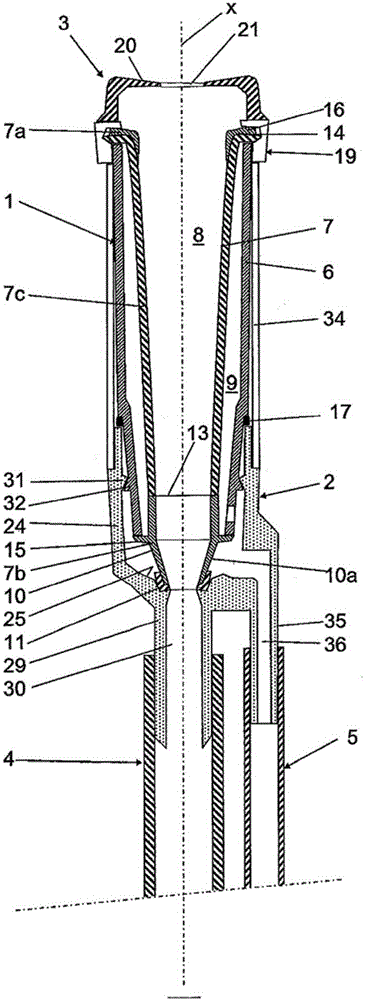

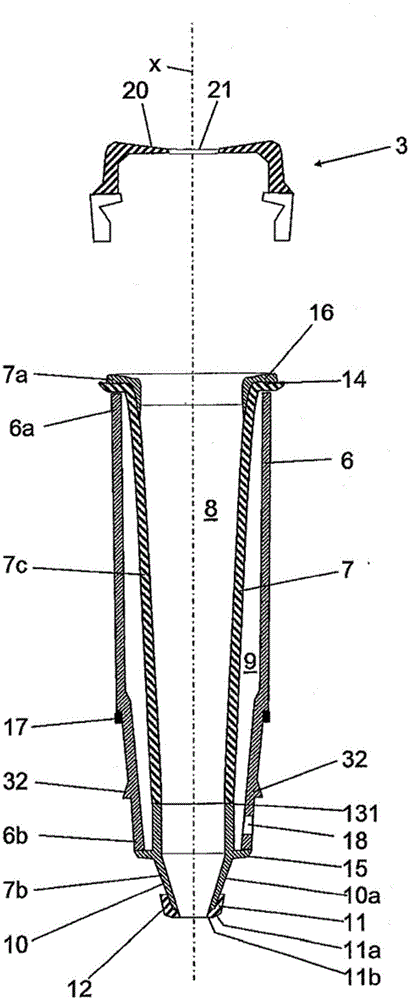

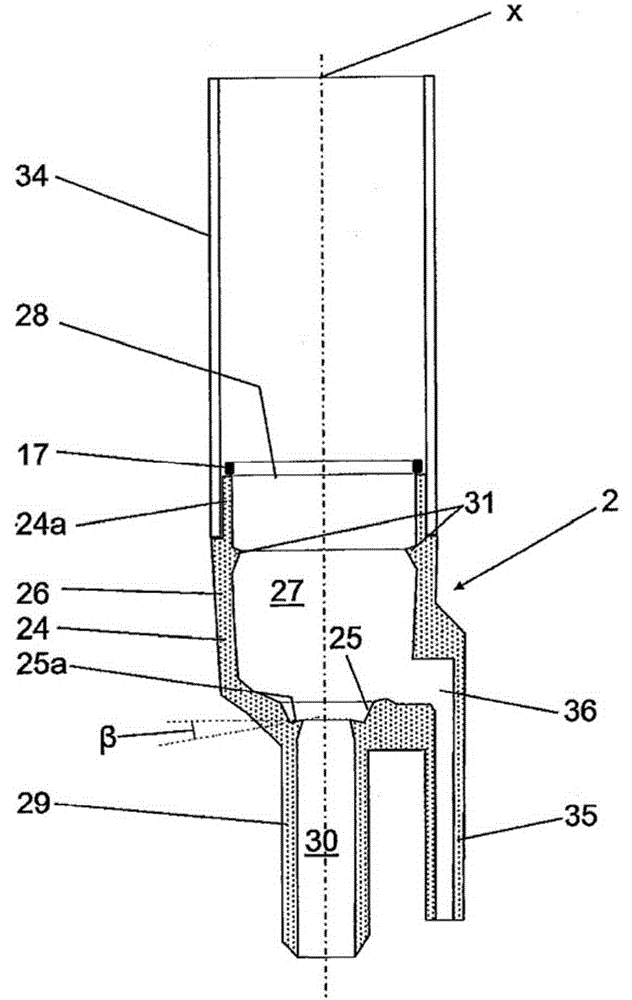

[0026] figure 1 A teat cup to be attached to the teat of an animal to be milked is disclosed. The teat cup comprises a milking cylinder 1 and a connector 2 . The teat cup may also comprise a flange member 3 . Furthermore, the teat cup may comprise or be connected to a milk tube 4 such as a so-called long milk tube. Furthermore, the teat cup can comprise or be connected to an impulse tube 5 such as a so-called long impulse tube.

[0027] The longitudinal center axis x extends through the teat cup along the teat cup, ie through the milking cylinder 1 , the connector 2 and the flange member 3 . When the milk tube 4 is in the figure 1 The longitudinal center axis x also extends through the upper part of the milk tube 4 along the upper part of the milk tube 4 in the resting state disclosed in .

[0028] Milking cartridge 1, see also figure 2 , including a sleeve 6 having an upper end 6a and a lower end 6b, and a teatcup inner sleeve 7 installed in the sleeve 6 . exist figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com