Tobacco flavonoid essence smoke beads and preparation method thereof

A flavonoid essence and flavonoid technology are applied in the directions of essential oils/spice, tobacco, application, etc., which can solve the problem of not being able to reduce harmful substances in smoking cigarettes, and achieve the effects of being convenient for popularization and application, having a wide range of sources and reducing phenol.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

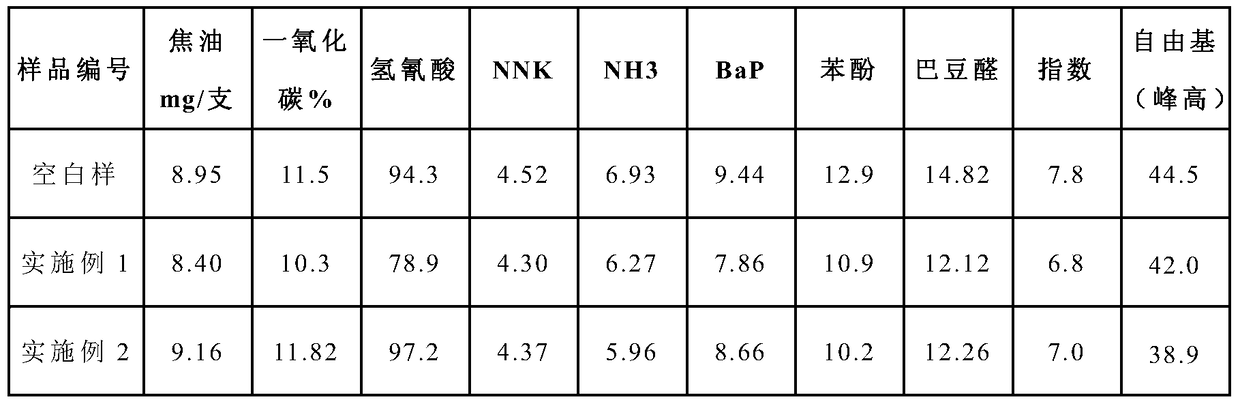

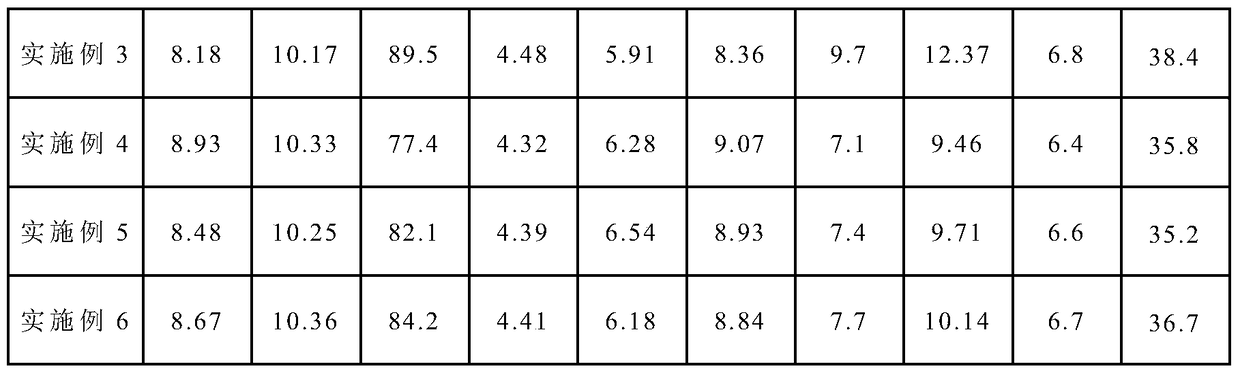

Examples

Embodiment 1

[0025] The flavonoid essence is mixed according to the ratio in Table 1, and the hydroxypropyl methylcellulose binder whose weight is 0.1% of the flavone essence weight is weighed, is added in the flavone essence after being dissolved in 400ml of water, stirred evenly to make a soft material, and then Extrude the soft material onto a spheronizer, extrude it into long and thin strips through the extruder, then spheronize it through the spheronizer, and dry it on the upper fluidized bed at a temperature of 60°C for 6 hours to obtain a particle size of 0.5mm , Flavonoid flavor smoke beads with a bulk density of 1.8g / ml.

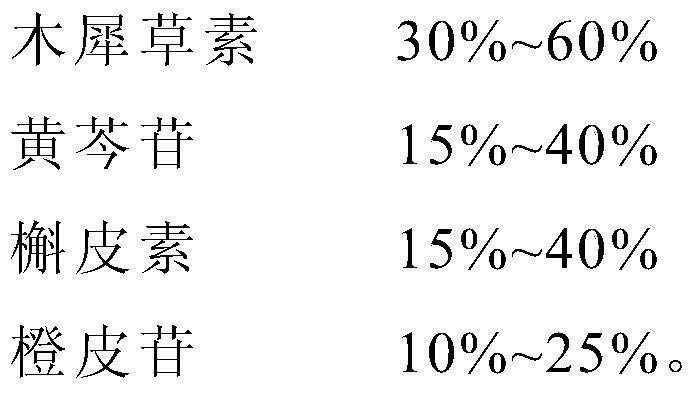

[0026] Table 1

[0027] Types of flavonoids

Embodiment 2

[0029] The flavone essence is mixed according to the ratio in Table 2, and the hydroxypropyl methylcellulose binder whose weight is 0.5% of the flavone essence weight is weighed, and after dissolving in 450ml of water, it is added in the flavone essence, stirred evenly to make a soft material, and then Extrude the soft material onto the spheronizer, extrude it into long and thin strips through the extruder, and then spheronize it through the spheronizer, and dry it on the upper fluidized bed at a temperature of 65°C for 5.5 hours to obtain a particle size of 0.8mm , Flavonoid flavor smoke beads with a bulk density of 1.6g / ml.

[0030] Table 2

[0031] Types of flavonoids

Embodiment 3

[0033] The flavone essence is mixed according to the ratio in Table 3, and the carboxymethyl cellulose binder with a weight of 0.8% of the flavone essence weight is taken, and after dissolving in 500ml of water, it is added in the flavone essence, stirred evenly to make a soft material, and then the soft Extrusion on the material - spheronizer, extruded into slender strips through the extruder, and then spheronized by the spheronizer, dried on the upper fluidized bed at a temperature of 70°C for 6 hours to obtain a particle size of 1.0mm, stack Flavonoid flavor smoke beads with a density of 1.6g / ml.

[0034] table 3

[0035] Types of flavonoids

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com