Full-automatic glue pouring mechanism capable of achieving long pipelines in deep sea

A fully automatic glue filling machine technology, applied in the field of glue filling machines, can solve the problems that the air in the cable tube cannot be fully discharged, affect the health of the body, and affect the quality of the glue filling, so as to achieve stable glue filling, space saving, and good quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

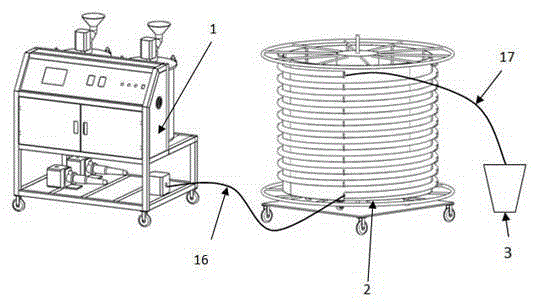

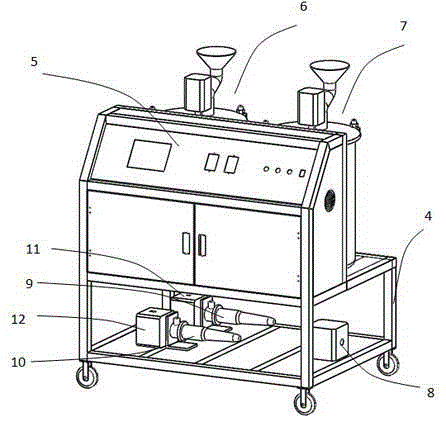

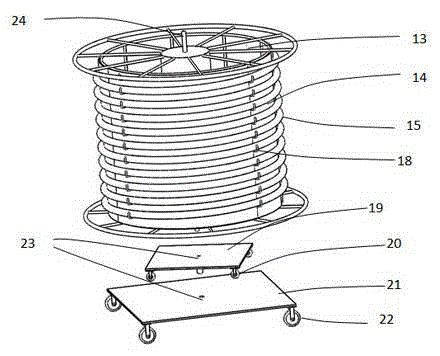

[0023] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the fully automatic glue filling machine 1 mechanism for realizing deep-sea long pipelines disclosed in this embodiment includes a mechanism body, and the mechanism body is composed of a fully automatic glue filling machine 1, a cable winding reel 2 and an overflow receiving barrel 3 ; The fully automatic glue filling machine 1 includes a frame 4, on which a control system 5, a pressure barrel, a mixer, a delivery pump and a drive motor are arranged; the cable winding reel 2 includes a combination The connected reel frame 13 , reel wall 14 and cable tube 15 .

[0024] A rubber inlet pipe 16 is provided between the fully automatic glue filling machine 1 and the cable winding reel 2 for connection, and an overflow pipe 17 is provided between the cable winding reel 2 and the overflow receiving barrel 3 for connection. The glue inlet pipe 16 is connected to the mixer and one end of the cable pipe, and the o...

Embodiment 2

[0026] Such as figure 1 , image 3 , Figure 4 and Figure 5 As shown, the fully automatic glue filling machine 1 mechanism for realizing deep-sea long pipelines disclosed in this embodiment includes a mechanism body, and the mechanism body is composed of a fully automatic glue filling machine 1, a cable winding reel 2 and an overflow receiving barrel 3 ; The fully automatic glue filling machine 1 includes a frame 4, on which a control system 5, a pressure barrel, a mixer, a delivery pump and a drive motor are arranged; the cable winding reel 2 includes a combination The connected reel frame 13 , reel wall 14 and cable tube 15 .

[0027] A rubber inlet pipe 16 is provided between the fully automatic glue filling machine 1 and the cable winding reel 2 for connection, and an overflow pipe 17 is provided between the cable winding reel 2 and the overflow receiving barrel 3 for connection. The glue inlet pipe 16 is connected to the mixer and one end of the cable pipe, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com