Making and forming method for model of siphon type water outlet passage of large pump station

A large-scale pumping station, siphon-type technology, used in water conservancy projects, hydroelectric power stations, buildings, etc., can solve the problems of lack of control errors, rough operation process, unable to meet the requirements of high-precision pump device model performance test, etc. Guaranteed accuracy and high forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

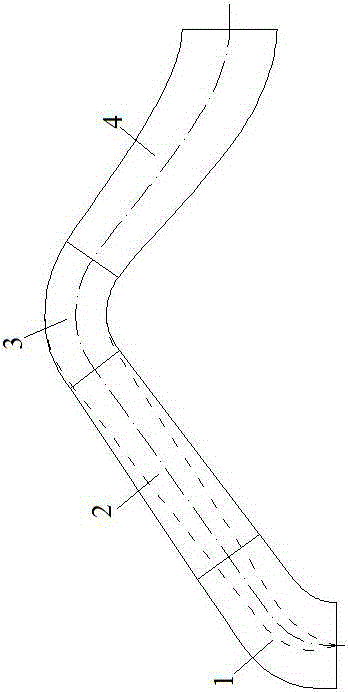

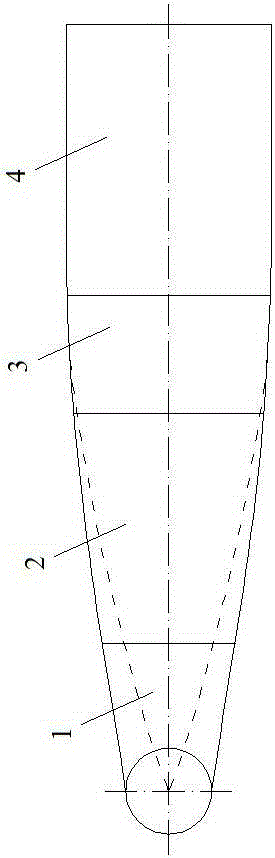

[0060] A large low-lift pumping station has an impeller diameter of 3000mm and adopts a siphon outlet channel. In order to meet the requirements of the model performance test of the pump device, a steel plate with a thickness of 5mm is required to make a model of the station's siphon outlet channel. The impeller diameter of the model pump to be used is 300mm, and the size ratio of the original model to the model is 10:1. The elevation one-line diagram and plane expansion one-line diagram of the flow channel model are shown in Fig. 1(a) and Fig. 1(b) respectively.

[0061] The steps of applying the present invention to make the siphon type water outlet channel model are as follows:

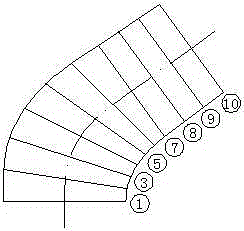

[0062] 1. The siphon type outlet flow channel model is divided into two sections A and B to make; the inlet section 1 of the siphon type water outlet flow channel model is the flow channel A section, the straight line section 2 and the hump section 3 of the siphon type water outlet flow channel mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com