Intelligent leveling and thickness determining machine

A rack and vertical motor technology, which is applied in the direction of machine tools suitable for grinding workpiece planes, grinding racks, and parts of grinding machine tools, and can solve the problems of maintaining the original position, high hardness of stone, and brittle texture , to achieve the effect of improving quality and polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

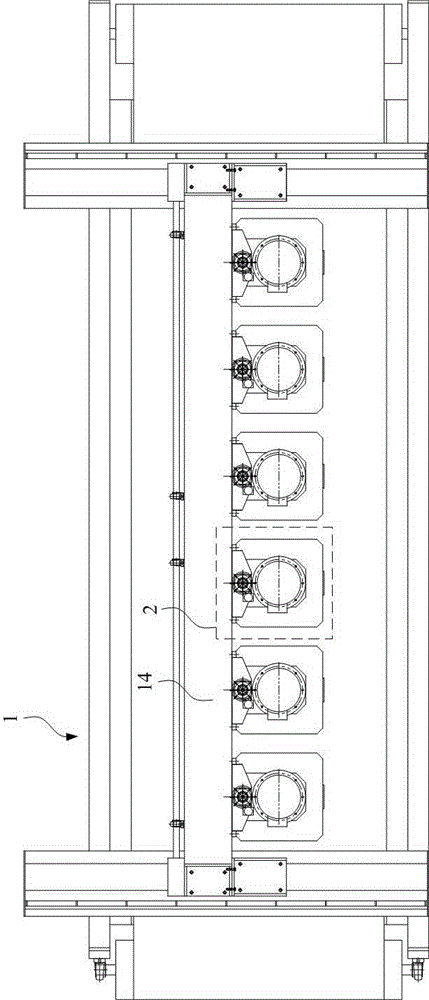

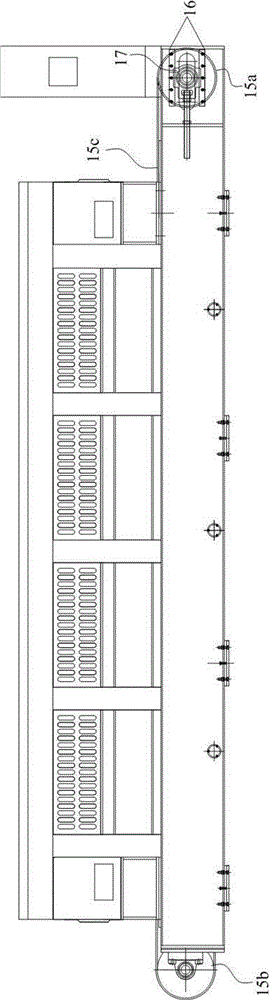

[0021] refer to figure 1 The schematic diagram of the structure is shown.

[0022] An intelligent leveling and calibrating machine according to an embodiment of the present invention includes several grinding head devices 2 arranged side by side on a frame 1 , and the grinding head device 2 includes a grinding disc driving device 21 and a grinding disc lifting adjustment device 23 .

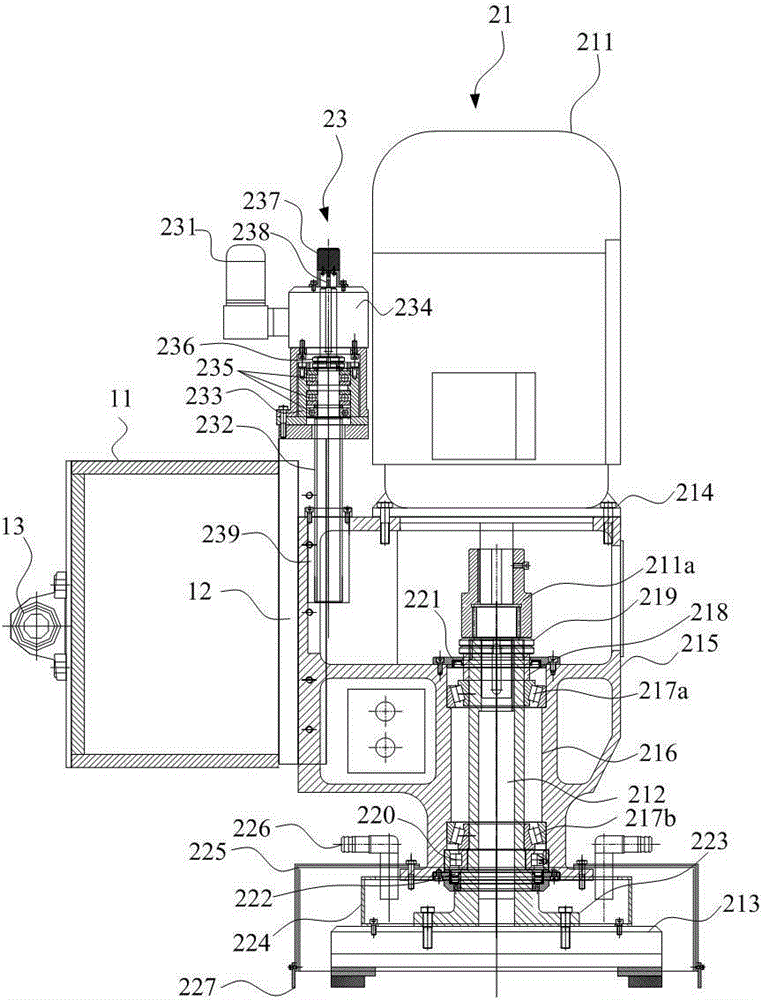

[0023] The disc drive unit 21 comprises a vertical motor 211, a main shaft 212, and a grinding head 213 fixedly mounted on the support, such as figure 2 The schematic diagram of the structure is shown.

[0024] The main shaft 212 is connected to the output end of the vertical motor 211 through a shaft coupling 211a. The support 214 has a support platform 215, and the support platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com