Production line for tiger-stripe bamboo floor

A bamboo floor and production line technology, applied to wood processing appliances, manufacturing tools, etc., can solve the problems of single color of bamboo floor and can not meet the diversification, and achieve the effect of convenient ingredients, saving transfer time and rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

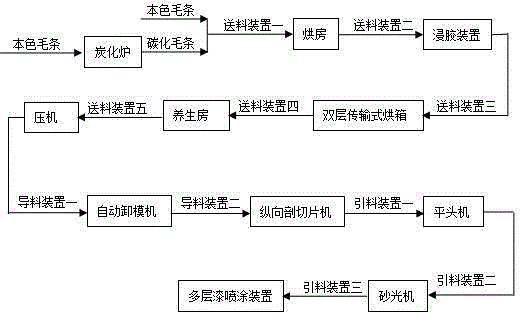

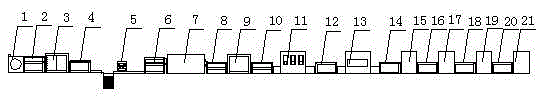

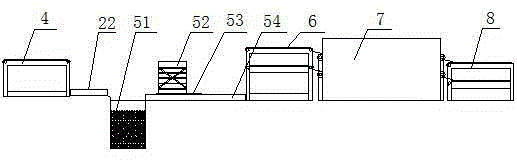

[0031] A production line for tiger pattern bamboo flooring, such as figure 2 , including carbonization furnace 1 for wool top carbonization, double-layer feeding device 1 2, drying room 3, side-by-side feeding device 4, dipping device 5, double-layer feeding device 2 6, double-layer transmission oven 7, double-layer feeding Device three 8, health care room 9, double-layer feeding device four 10, press machine 11, material guide device one 12, automatic mold unloading machine 13, material guide device two 14, longitudinal section slicer 15, material guide device one 16 arranged in sequence , flat head machine 17, feeding device two 18, sanding machine 19, feeding device three 20, multi-layer paint spraying device 21, double-layer feeding device one 2 is set between carbonization furnace 1 and drying room 3, and side by side feeding device 4 is set Between the drying room 3 and the dipping device 5, the double-layer feeding device 1 2 has the same structure as the double-layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com