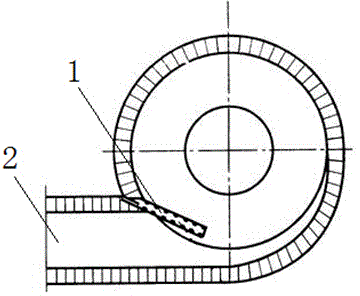

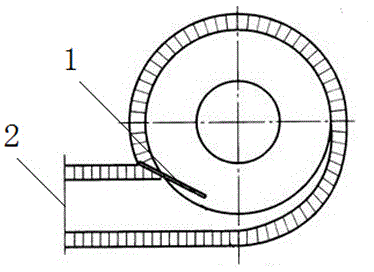

Method for pouring guide plate of cyclone preheater of cement dry-process kiln

A technology of cyclone preheater and pouring method, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of easy monetization, short service life and corrosion of the deflector, and reduce the difficulty of operation. , The effect of improving quality performance and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A pouring method for a deflector of a cyclone preheater of a cement dry process kiln, comprising the steps of frame welding, batching, stirring, first pouring, second pouring, third pouring, and shaping;

[0027] Specific steps:

[0028] A. Frame welding: Weld the heat-resistant round steel made of 1Crl8Ni9Ti into a frame with a thickness of 100mm, the height of the frame is 3000mm, and the distance between the heat-resistant round steel and the heat-resistant round steel is set to 150mm. Evenly coated with paraffin wax with a thickness of 5mm;

[0029] B. Ingredients: Mix ultra-high-strength wear-resistant castables with water and fiber (weight ratio: 100:4:7) to make castables. The heat-resistant temperature of castables is ≤1650°C. Under the conditions of 1100°C and 24h The compressive strength ≥ 120MPa, wear resistance ≤ 8;

[0030] C, stirring: the castable is stirred with a powerful mixer, the rotating speed is controlled to be 800r / min, and the stirring time is...

Embodiment 2

[0036] A pouring method for a deflector of a cyclone preheater of a cement dry process kiln, comprising the steps of frame welding, batching, stirring, first pouring, second pouring, third pouring, and shaping;

[0037] Specific steps:

[0038] A. Frame welding: Weld the heat-resistant round steel made of 1Crl8Ni9Ti into a frame with a thickness of 120mm, the height of the frame is 3400mm, and the distance between the heat-resistant round steel and the heat-resistant round steel is set to 165mm. Evenly coated with paraffin wax with a thickness of 3mm;

[0039] B. Ingredients: mix ultra-high-strength wear-resistant castable with water and fiber (100:5.5:9 by weight) to make castable. The compressive strength ≥ 120MPa, wear resistance ≤ 8cc;

[0040] C, stirring: the castable is stirred with a powerful mixer, the speed is controlled to be 1200r / min, and the stirring time is controlled to be 7min;

[0041] D, pouring for the first time: wrap described framework with wooden for...

Embodiment 3

[0046] A pouring method for a deflector of a cyclone preheater of a cement dry process kiln, comprising the steps of frame welding, batching, stirring, first pouring, second pouring, third pouring, and shaping;

[0047] Specific steps:

[0048] A. Frame welding: weld the heat-resistant round steel material of 1Crl8Ni9Ti into a frame with a thickness of 115mm, the height of the frame is 3100mm, and the distance between the heat-resistant round steel and the heat-resistant round steel is set to 200mm. Evenly coated with paraffin wax with a thickness of 10mm;

[0049] B. Ingredients: mix ultra-high-strength wear-resistant castable with water and fiber (100:6:10 by weight) to make a castable. The heat-resistant temperature of the castable is ≤1650°C and the compressive strength is 1200°C× 24h≥150MPa, wear resistance≤9cc;

[0050] C, stirring: the castable is stirred with a powerful mixer, the speed is controlled to be 1300r / min, and the stirring time is controlled to be 8min;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com