Clamping box for glass substrate storage

A glass substrate and memory card technology, which is applied to the packaging of vulnerable items, internal accessories, and types of packaged items. accidents, improving the efficiency of fragment treatment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

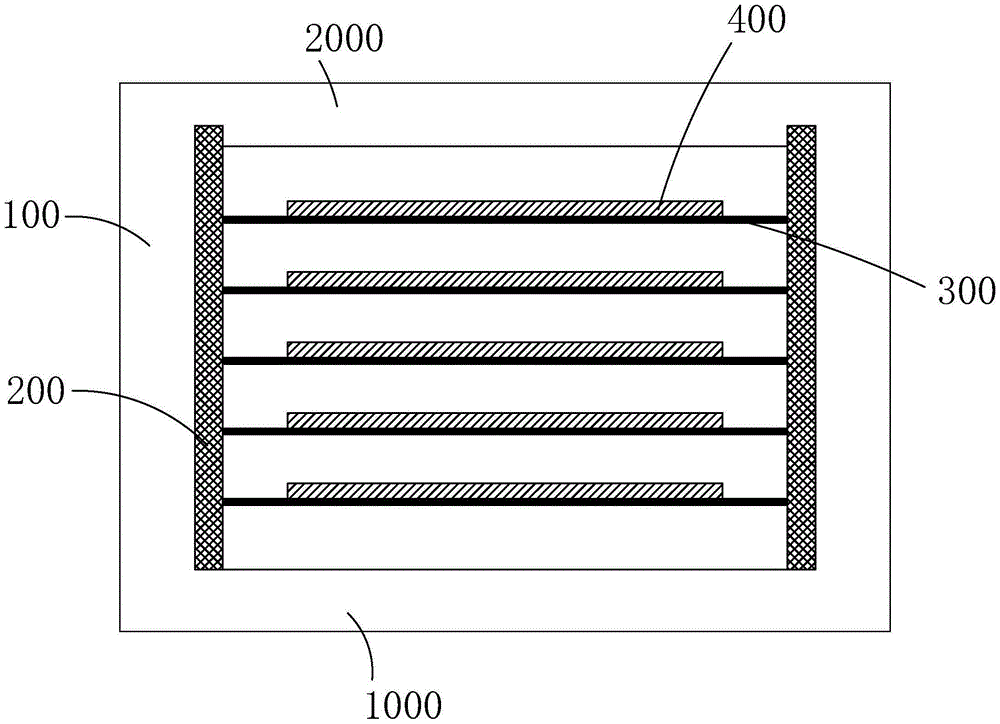

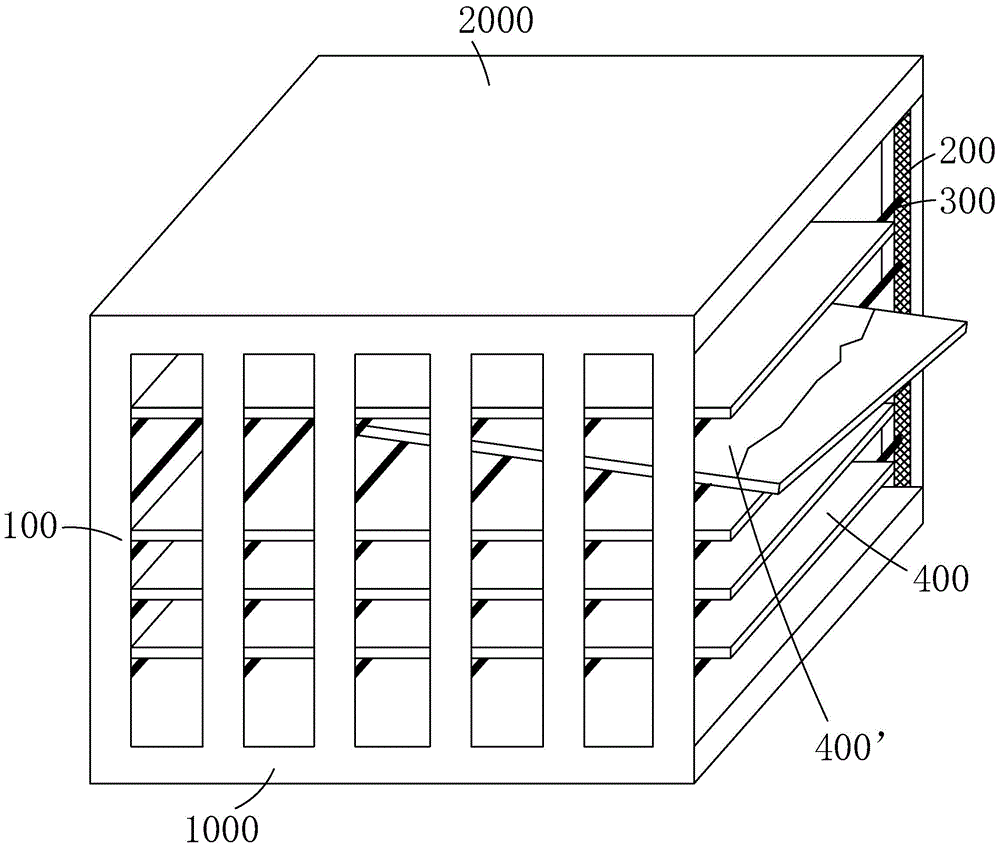

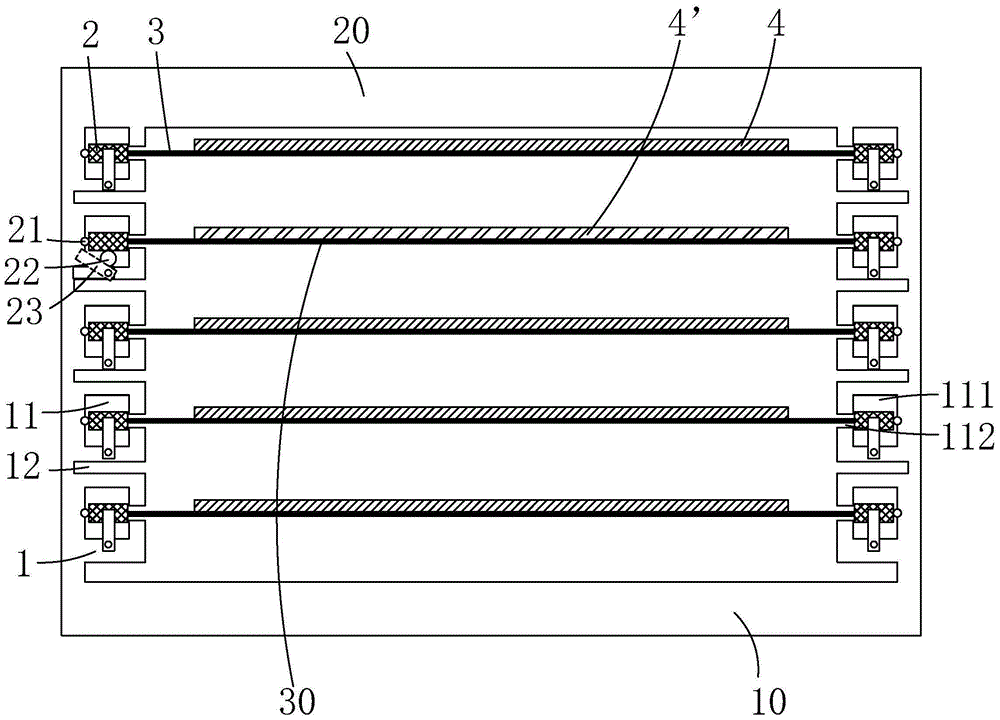

[0029] see Figure 3 to Figure 8 , the present invention provides a glass substrate storage cassette, comprising: a bottom plate 10, a top plate 20 opposite to the bottom plate 10, several side bars 1 connected to the opposite sides between the bottom plate 10 and the top plate 20, connecting Several layers of supporting units 30 between the plurality of side bars 1 and parallel to the bottom plate 10 , and auxiliary trays 5 .

[0030] The inner side of the side bar 1 is provided with a plurality of first draw-in slots 11 and a plurality of second draw-in slots 12 at intervals along the vertical direction, and a second draw-in slot 12 is provided below each first draw-in slot 11; A first card slot 11 and each second card slot 12 extend along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com