Overturning and correction mechanism of backlight source module laminator

A film laminating machine and backlight technology, applied in object supply, pile separation, thin material processing, etc., can solve problems such as difficulty, high stability requirements, and low efficiency, and achieve low cost, high stability, and structural flexibility high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

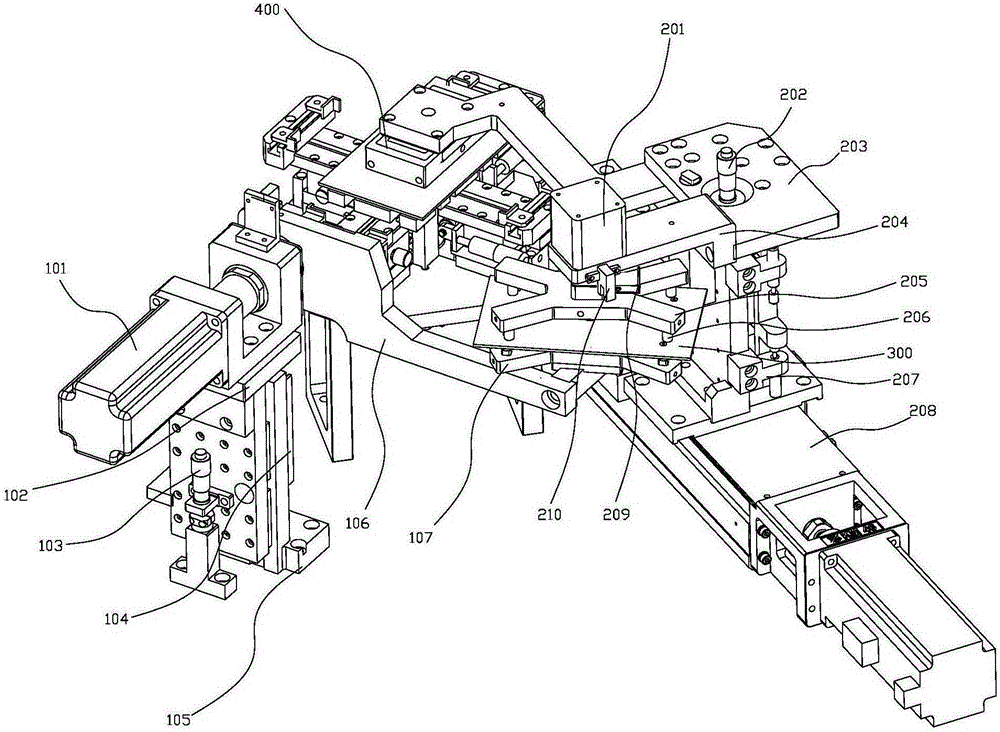

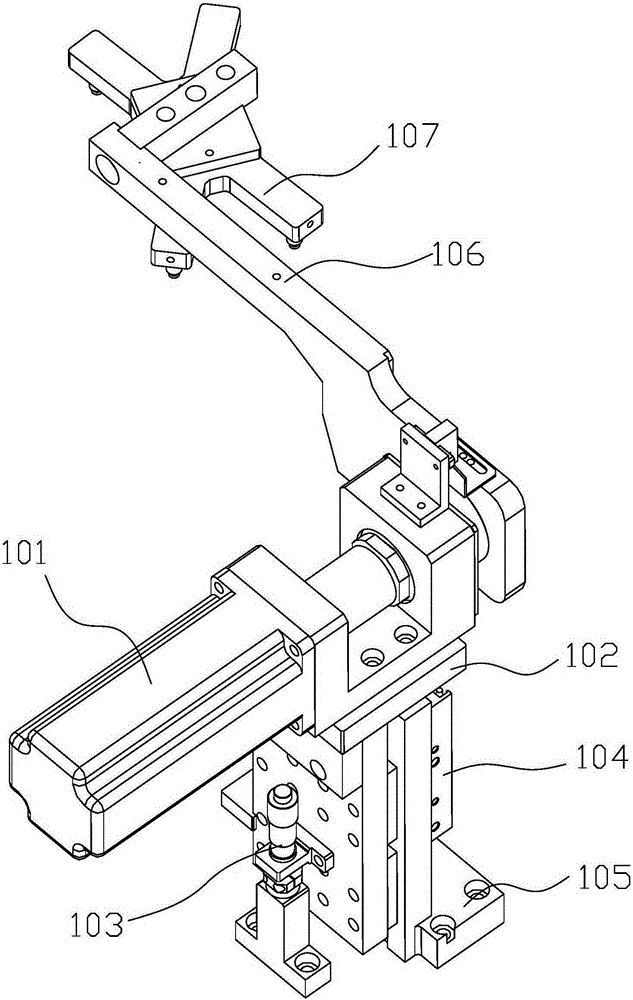

[0018] A flipping and guiding mechanism of a backlight module laminating machine, please refer to Figure 1 to Figure 2 , including an overturning device and a guiding device; the overturning device includes an overturning base 105, on which a rotating arm 106 is rotated, and the end of the rotating arm 106 is provided with a suction cup 107, and the rotating arm 106 rotates When the suction position is reached, the suction cup 107 is facing downward to absorb the diaphragm (refer to figure 2 ), when the rotating arm 106 rotates to the guiding position, the suction cup 107 releases the diaphragm upwards (refer to figure 1 ); the guiding device includes a guiding support plate 204 translated by the conveying device 208, a guiding driving device 201 is fixed on the guiding supporting plate 204, and the guiding driving dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com