Preparation method of micro-nano bending structure

A bending and micro-nano technology, applied in the field of micro-nano, can solve problems such as poor orientation of structural space, inability to meet the needs of scientific research and processing, high time and cost costs, etc., to achieve flexible controllability, clear processing mechanism and formation principle , the effect of large preparation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

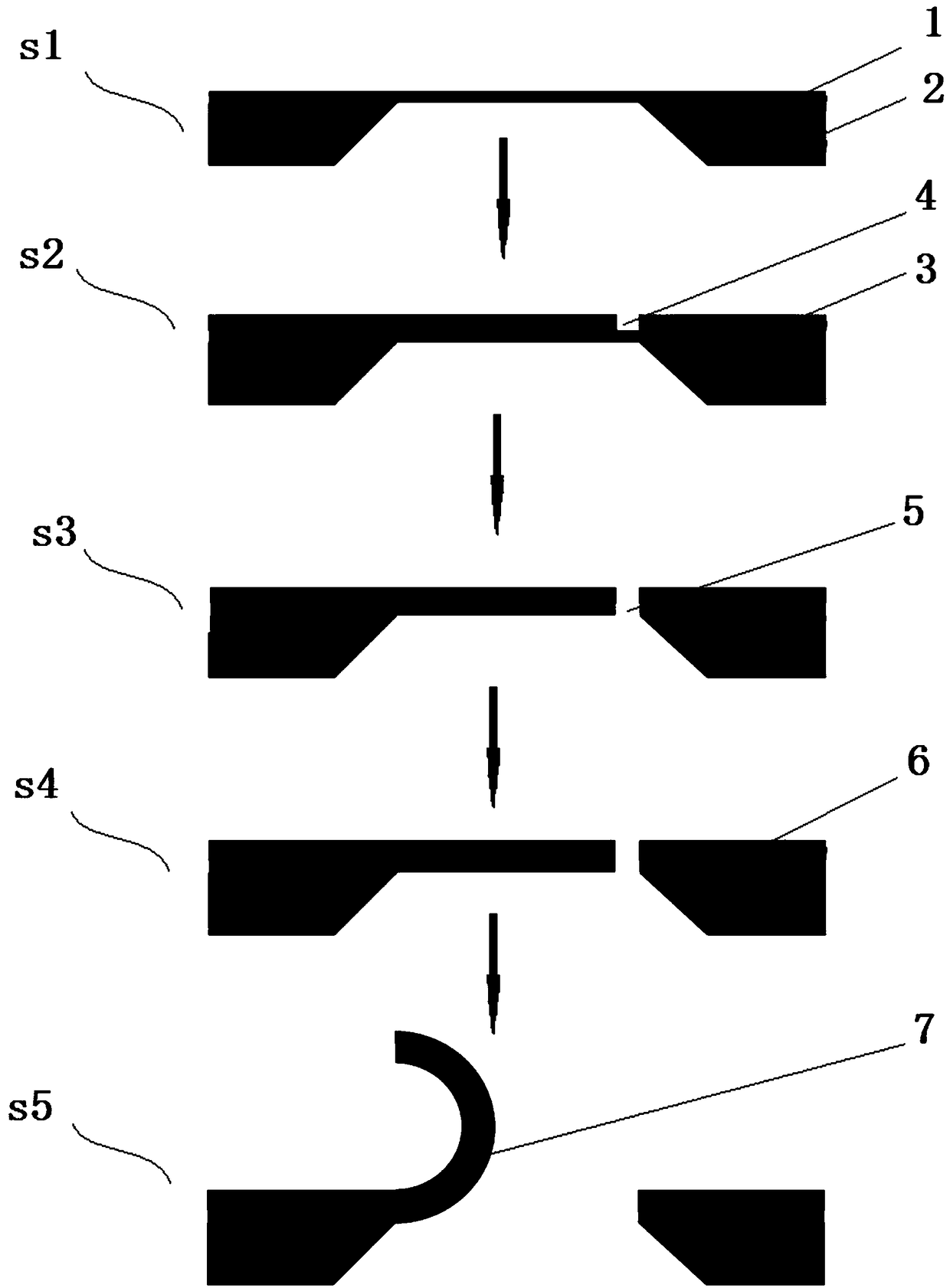

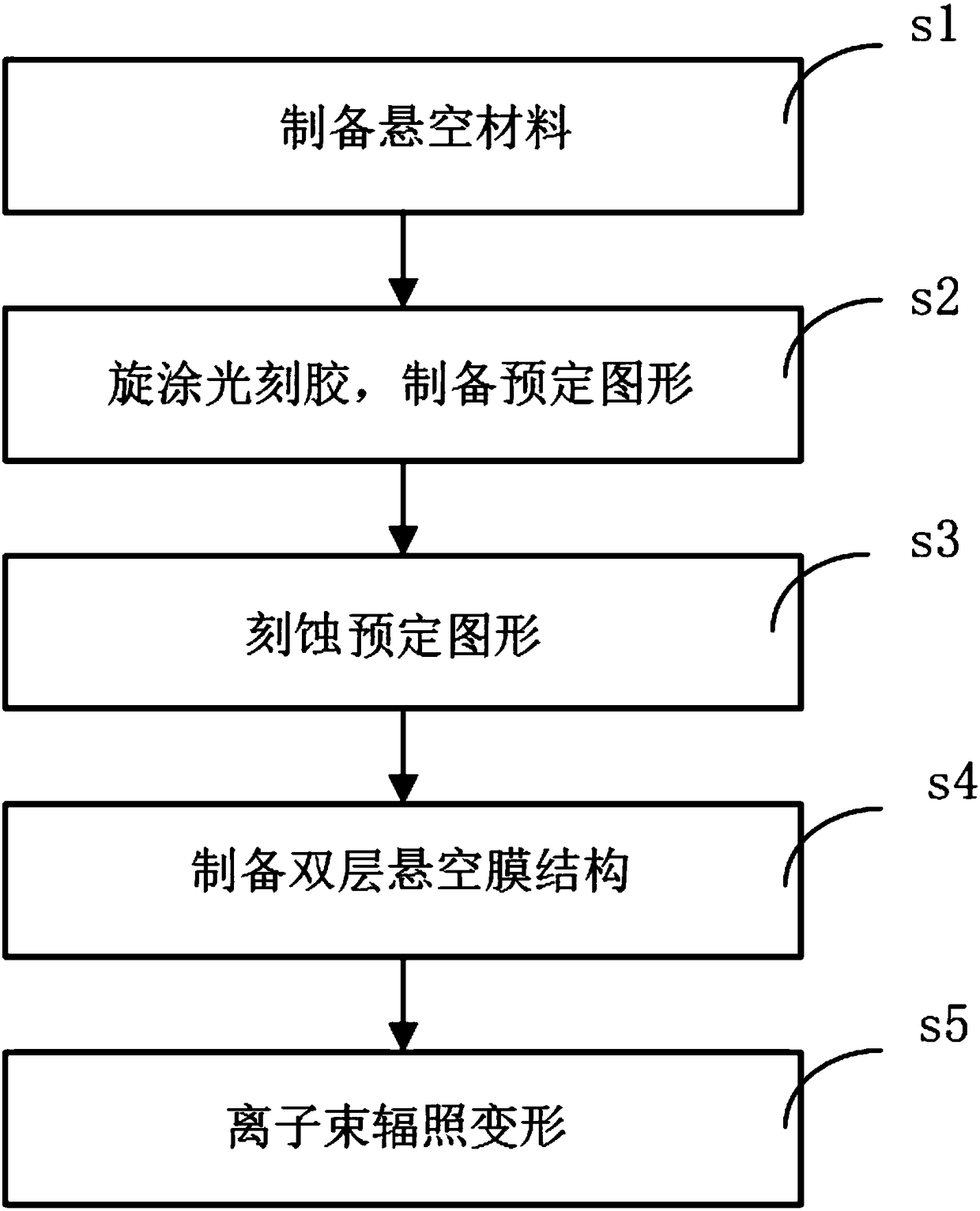

[0031] figure 1 It is a schematic diagram of the fabrication process of a fabrication method of a micro-nano curved structure according to an embodiment of the present invention. figure 2 It is a schematic flowchart of a method for preparing a micro-nano curved structure according to an embodiment of the present invention. Such as figure 1 and figure 2 As shown, the preparation method of a micro-nano curved structure provided by the present invention is to introduce a stress change to make it bend by irradiating the surface of the suspended double-layer film, and then control the shape of the two-dimensional film by changing the irradiation energy. The degree of bending specifically includes the following steps:

[0032] s1. Prepare the suspended material 1 on the substrate 2;

[0033] s2. Spin-coat photoresist 3 on the suspended material 1, and prepare predetermined pattern 4 by exposing photoresist 3;

[0034] s3, transfer the predetermined pattern 4 to the suspended ...

Embodiment 1

[0046] Step 1: Purchase a commercial 20nm silica window and clean it under oxygen plasma for 20 seconds;

[0047] Step 2: Spin-coat electron beam photoresist PMMA on the purchased silicon substrate at a speed of 4000r / min, and then place it on a 180°C hot plate and bake for 1min;

[0048] Step 3: Use the electron beam exposure process to expose the sample obtained in step 2. The exposed pattern is set as the inverse pattern of the stripe pattern, and the PMMA developer is used for development, and the unmasked parts are removed by reactive ion etching. Silica Graphics;

[0049] Step 4: Remove the photoresist PMMA from the sample obtained in step 3 by oxygen plasma etching, and deposit 40 nanometers of gold by thermal evaporation process;

[0050] Step 5: The sample obtained in step 4 is placed under the ion beam generated by reactive ion etching, and the sample is treated with oxygen plasma to obtain a three-dimensional curved structure.

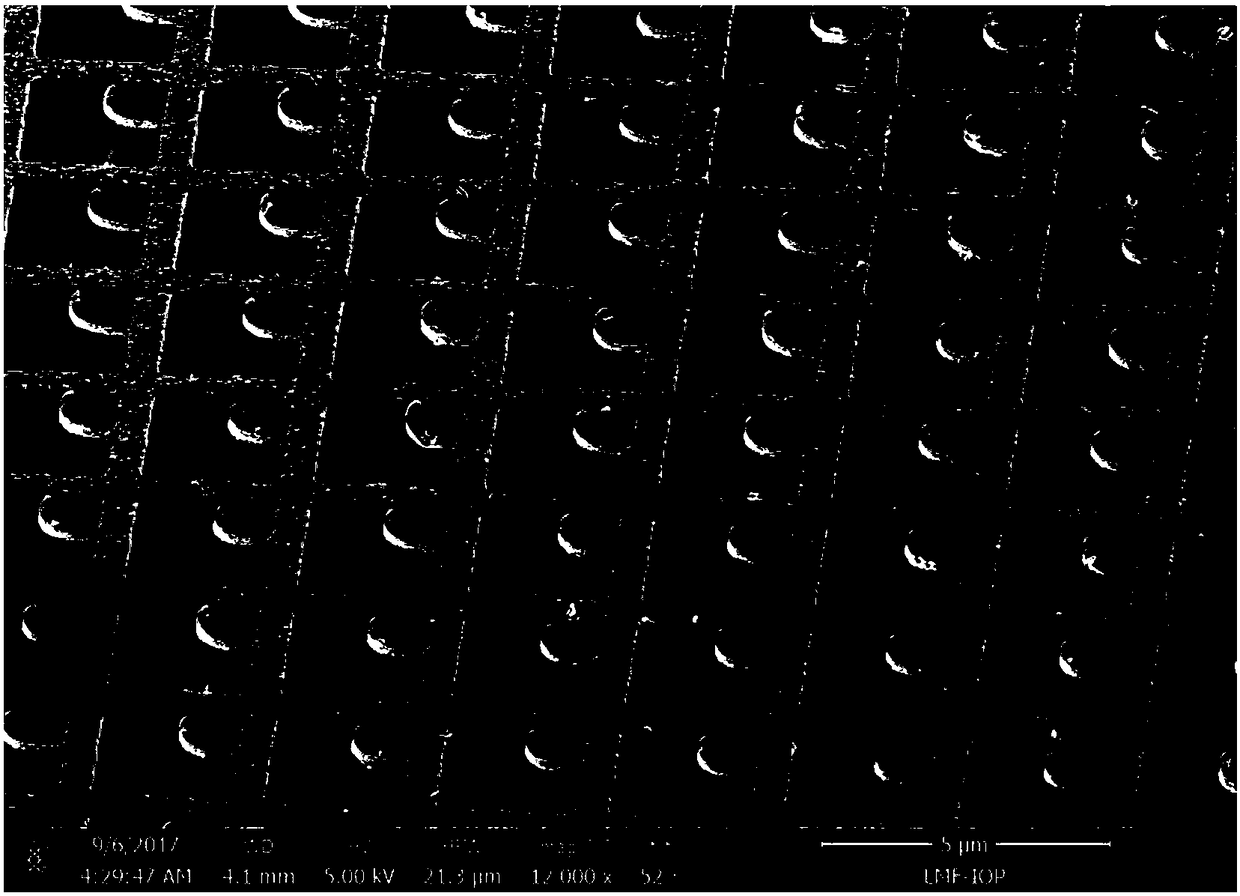

[0051] The pattern of the three-dim...

Embodiment 2

[0053] Step 1: Deposit 100 nanometers of Au on a clean silicon wafer coated with a sacrificial layer by electron beam deposition, and transfer the gold film to a copper grid for TEM in an acetone environment to obtain a suspended gold window;

[0054] Step 2: Spin-coat UV photoresist S1813 on the transferred gold window at a speed of 3000r / min, and then bake on a hot plate at 115°C for 1min;

[0055] Step 3: Use the electron beam exposure process to expose the sample obtained in step 2. The exposed pattern is set as the inverse pattern of the "T" pattern, develop with S1813 developer, and use ion milling to remove the unmasked gold. graphics;

[0056] Step 4: Use acetone to remove the photoresist S1813 from the sample obtained in step 3; use pulsed laser deposition process to deposit TiO 2 40 nanometers;

[0057] Step 5: Place the sample obtained in step 4 under ion milling, and irradiate the sample with argon plasma to obtain a three-dimensional curved structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com