Bi-directional ventilation superficial-layer static composting device and method for composting by utilizing same

A composting and static technology, which is applied in fertilization equipment, preparation and application of organic fertilizers, etc., can solve the problems of large odor of mechanical turning, large amount of conditioner, and large occupied area, so as to save occupied area and improve Oxygen supply capacity, avoiding the effect of drying too quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

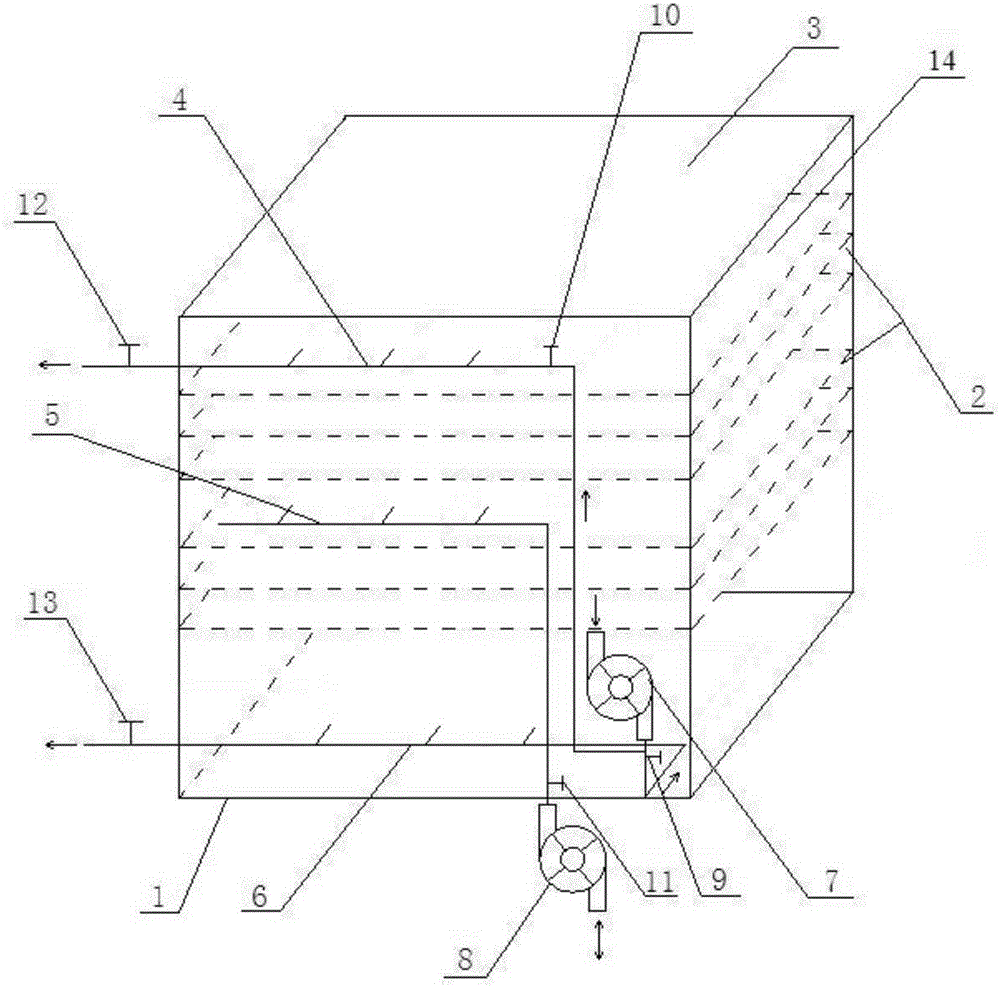

[0038] Specific implementation mode one: combine figure 1Describe this embodiment, the two-way ventilated shallow layer static composting device of this embodiment comprises fermentation bin 1, fermentation tank 2, fermentation bin top cover 3, side wall 14, upper air inlet and outlet pipe 4, middle air inlet and outlet pipe 5, lower air inlet and outlet pipe 6, upper and lower Part ventilation fan 7, middle ventilation fan 8, bottom inlet valve 9, top inlet valve 10, middle inlet and outlet valve 11, top exhaust valve 12 and bottom exhaust valve 13, the top of the fermentation bin 1 is provided with a fermentation bin top Cover 3, the right side of the fermentation chamber 1 is provided with an openable and closed side wall 14, the bottom of the fermentation chamber 1 is laid with a lower air inlet and outlet pipe 6, and the inlet end of the lower air inlet and outlet pipe 6 is connected to the air outlet of the upper and lower ventilation fans 7 through a pipe , the outlet e...

specific Embodiment approach 2

[0039] Embodiment 2: This embodiment differs from Embodiment 1 in that: the depth of the fermentation tank 2 is 0.2-1.0 m. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0040] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the bottom of the fermentation tank 2 is made of a perforated plate or a porous screen. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com