Fluorescent stamp-pad ink with anti-counterfeiting function and preparation method thereof

A fluorescent and ink-based technology, applied in the field of printing inks for anti-counterfeiting labels, can solve problems such as the inability to mark products of different materials, the weak ability to adapt to a variety of materials, discoloration, and the lightening of pattern colors, etc., and achieve good stability. Good stability and adhesion, stable imprinting performance, small diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

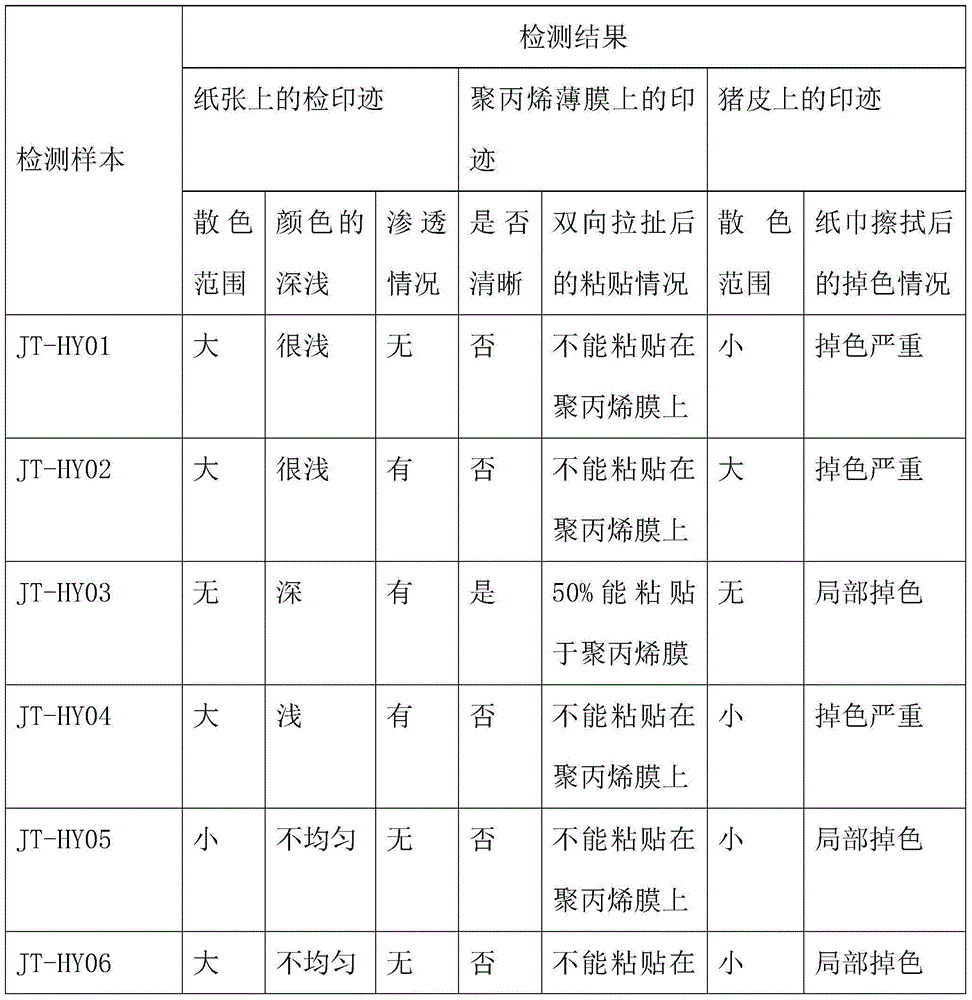

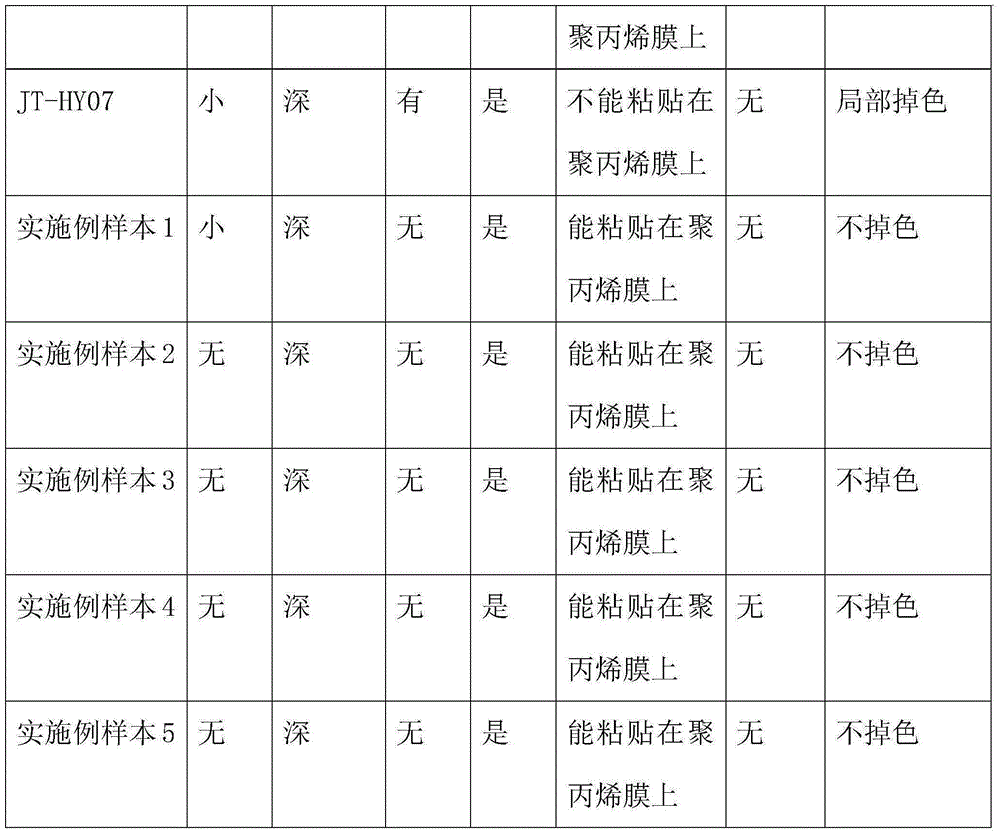

Examples

Embodiment 1

[0025] A fluorescent printing oil with anti-counterfeiting function, its ingredients include: 15 parts of castor oil, 15 parts of terbium nitrate, 30 parts of 2,4-dihydroxybenzoic acid, 200 parts of triethylamine, 200 parts of industrial alcohol, 300 parts of n-butyl Alcohol, 6 parts of slip agent, 35 parts of anti-wear agent, appropriate amount of red pigment and 40 parts of film-forming material.

[0026] The preparation method of above-mentioned fluorescent printing oil is characterized in that, comprises the steps:

[0027] Step 1) Preparation of fluorescent liquid:

[0028] A, under normal temperature conditions, 30 parts of castor oil, 200 parts of triethylamine, 200 parts of industrial alcohol solvent and 300 parts of n-butanol are mixed and stirred;

[0029] B, the mixed solution obtained after the previous step is heated to 40 degrees, and 15 parts of terbium nitrate are added while stirring at 60 rpm, then continue to stir for 3 minutes, and be incubated at 40 degre...

Embodiment 2

[0037] A fluorescent printing oil with anti-counterfeiting function, its ingredients include: 20 parts of castor oil, 10 parts of terbium nitrate, 30 parts of 2,4-dihydroxybenzoic acid, 200 parts of triethylamine, 200 parts of industrial alcohol, 300 parts of n-butyl Alcohol, 5 parts of slip agent, 5 parts of anti-wear agent, 10 parts of preservative, appropriate amount of green pigment and 50 parts of film-forming material.

[0038] The preparation method of above-mentioned fluorescent printing oil is characterized in that, comprises the steps:

[0039] Step 1) Preparation of fluorescent liquid:

[0040] A, under normal temperature conditions, 20 parts of castor oil, 200 parts of triethylamine, 200 parts of industrial alcohol solvent and 300 parts of n-butanol are mixed and stirred;

[0041] B. Heat the mixed solution obtained after the previous step to 40 degrees, and add 10 parts of terbium nitrate while stirring at 60 rpm, then continue to stir for 3 minutes, and keep the...

Embodiment 3

[0050] A fluorescent printing oil with anti-counterfeiting function, its ingredients include: 18 parts of castor oil, 13 parts of terbium nitrate, 25 parts of 2,4-dihydroxybenzoic acid, 180 parts of triethylamine, 160 parts of industrial alcohol, 270 parts of n-butyl Alcohol, 6 parts of slip agent, 11 parts of antiseptic, appropriate amount of red pigment and 50 parts of film-forming material.

[0051] The preparation method of above-mentioned fluorescent printing oil is characterized in that, comprises the steps:

[0052] Step 1) Preparation of fluorescent liquid:

[0053] A, under normal temperature conditions, 18 parts of castor oil, 180 parts of triethylamine, 160 parts of industrial alcohol solvent and 270 parts of n-butanol are mixed and stirred;

[0054] B, the mixed solution obtained after the previous step is heated to 40 degrees, and 13 parts of terbium nitrate are added while stirring at 60 rpm, then continue to stir for 3 minutes, and be incubated at 40 degrees; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com