A kind of solvent-based rubber adhesive and preparation method thereof

A rubber adhesive and solvent-based technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve problems affecting bonding, plasticizer migration, etc., achieve reduced volatile odor, good barrier performance, and improved dispersion The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

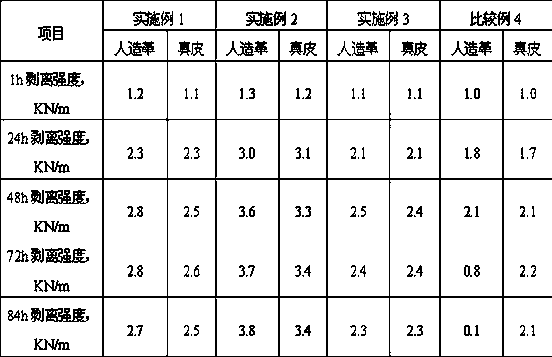

Examples

Embodiment 1

[0029] Add 20 parts of cyclohexane, 10 parts of ethyl acetate, and 20 parts of 6# solvent oil into the reaction kettle, start the motor to stir, add 10 parts of phenolic resin, 5 parts of rosin glyceride, 5 parts of petroleum resin, and 10 parts of terpene resin , 0.5 parts of high-activity magnesium oxide, 0.5 parts of N-methyl-2-pyrrolidone, stirred until uniformly dissolved; then added 20 parts of thermoplastic styrene-butadiene rubber, stirred until uniformly dissolved; finally added 1.875 parts of nano silicon dioxide in turn: β- 2.5 parts of cyclodextrin: 0.625 parts of silane coupling agent KH-550, 0.15 parts of flaky zinc powder, 0.15 parts of mica powder, mix well and discharge.

Embodiment 2

[0031] Add 20 parts of ethyl acetate, 20 parts of acetone, 20 parts of 6# solvent oil into the reaction kettle, start the motor to stir, add 5 parts of phenolic resin, 5 parts of petroleum resin, 5 parts of coumarone resin, 5 parts of terpene resin, 1.3 parts of zinc oxide, 0.1 part of water, stir until dissolved; then add 10 parts of neoprene, stir until dissolved; finally add 0.328 parts of nano-calcium carbonate: 1.64 parts of β-cyclodextrin: silane coupling agent KH- 0.033 parts of 570, 0.085 parts of flaky zinc powder, 4.099 parts of mica powder, and 0.82 parts of talc powder, mix well and discharge.

Embodiment 3

[0033] Add 30 parts of methyl acetate, 5 parts of acetone, and 10 parts of 6# solvent oil into the reaction kettle, start the motor to stir, add 2.5 parts of rosin, 2.5 parts of phenolic resin, 0.5 parts of high-activity magnesium oxide, 0.3 parts of zinc oxide, N- 0.3 parts of methyl-2-pyrrolidone, stirred until uniformly dissolved; then added 8 parts of thermoplastic styrene-butadiene rubber, 2 parts of nitrile rubber, and 2 parts of polyisobutylene rubber, stirred until uniformly dissolved; finally, 0.11 parts of nano-montmorillonite were added successively: 0.005 parts of β-cyclodextrin: 0.005 parts of silane coupling agent A-151, 4.445 parts of flaky zinc powder, 4.445 parts of mica powder, 1.112 parts of talcum powder, mix well and discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com