Method and system for converting ultrahigh-temperature waste into hydrogen oil

An ultra-high temperature and waste technology, applied in the field of hydrogen energy, can solve the problems of poisonous fuel cells, low capacity, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

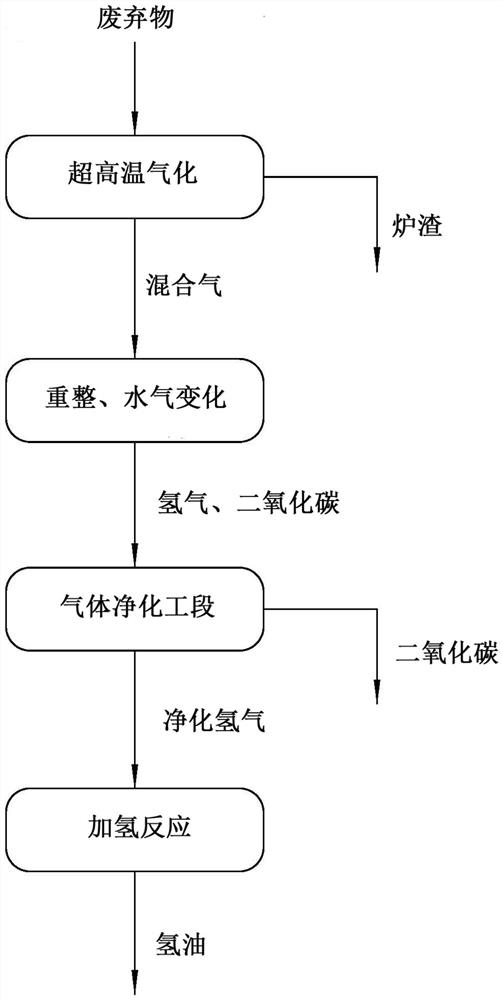

[0034] Such asfigure 1 The flow chart of the method for converting high-temperature waste into hydrogen-producing oil is shown. Firstly, the waste is compressed and then gasified at an ultra-high temperature to generate a mixed gas. The gasification temperature is 1600°C.

[0035] The waste is municipal waste, industrial waste or biomass.

[0036] The mixed gas undergoes a reforming reaction under the action of a highly selective reaction catalyst to generate crude synthesis gas, and then undergoes a water-gas shift reaction to obtain hydrogen and carbon dioxide. Crude synthesis gas includes CO, H 2 , CO 2 .

[0037] The highly selective reaction catalyst is a supported catalyst, the active component is a mixture of Ni and Cr, and the carrier is TiO 2 .

[0038] The hydrogen passes through the gas purification process to obtain purified hydrogen, and the purity of the purified hydrogen is 85%. The gas purification process is carried out in the purification device, includi...

Embodiment 2

[0047] First, the waste is gasified at ultra-high temperature to generate a mixed gas, and the gasification temperature is 1200°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com