A kind of domestic waste incineration fly ash solidification processing method

A technology for domestic waste incineration and fly ash solidification, which is applied in the field of waste incineration and fly ash treatment, and can solve the problems of lack of application of control factors for heavy metal leaching from incineration fly ash, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

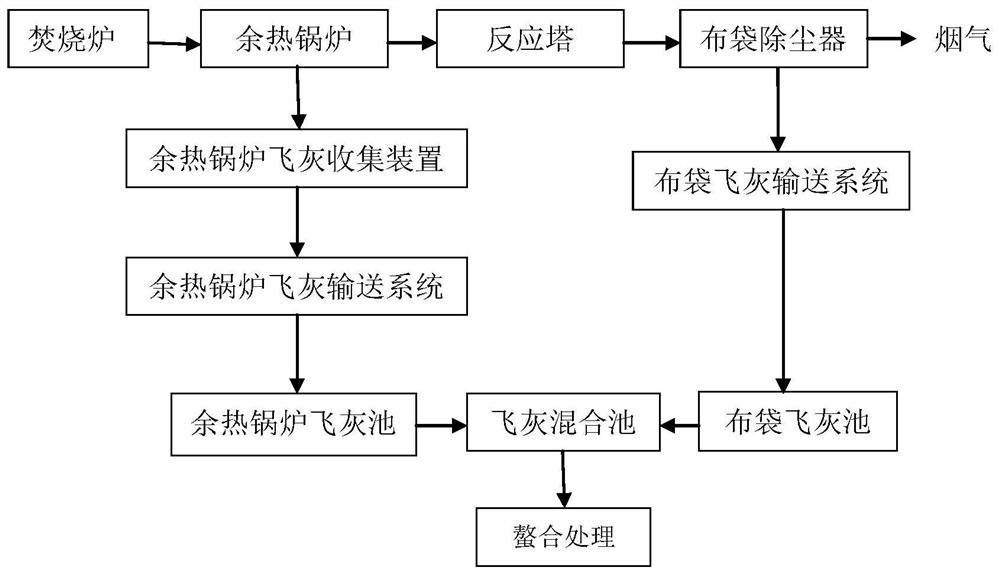

Method used

Image

Examples

experiment example 1

[0043] The outlet temperature of the reaction tower in the domestic waste incineration fly ash solidification treatment method was set to 150°C, 155°C, 160°C, and 165°C respectively, and the influence of the reaction tower outlet temperature on the properties such as the index value of the bag fly ash was explored. The results are shown in Table 1 shown.

[0044] Table 1 Effect of reaction tower outlet temperature on properties of bagged fly ash

[0045]

[0046] From Table 1, it can be found that the outlet temperature of the reaction tower has a particularly obvious influence on the amount of lime. Within this temperature range, as the temperature rises, the index value of the fly ash rises. This is because at different temperatures, the lime slurry solution and the acidity The efficiency of the index reaction is not the same, so the dosage changes significantly. As the outlet temperature of the reaction tower rises, the amount of lime increases, resulting in more lime r...

experiment example 2

[0048] Using the solidification treatment method for domestic waste incineration fly ash of the present invention to treat three domestic waste incineration treatment lines, set the temperature of the reaction tower to 162°C, follow up and study the Index value of the bag fly ash of each reaction tower, and found that the semi-dry reaction tower The daily index fluctuations of fly ash range from 76 to 162, 64 to 184, and 96 to 184, respectively; the fluctuation trend of the index value of fly ash in reaction tower bags is basically the same, which may be mainly caused by the change of garbage composition and the degree of combustion fluctuations. In addition, the fluctuation trend of the index value of the bag ash of the three furnaces and the acidity index SO 2 , HCl showed a more obvious negative correlation, when the acid index is low, the Index value of the bag fly ash will increase significantly. From this experimental example, it can be concluded that the Index value of...

experiment example 3

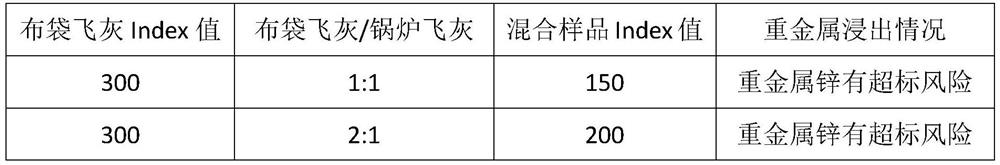

[0050] The samples with the index value of the bagged fly ash in the range of 150-350 were selected to be mixed with the waste heat boiler fly ash respectively, and the effects of the index value and mixing ratio of the bagged fly ash on the properties of the mixed fly ash, the leaching toxicity of heavy metals and the difficulty of fly ash treatment were explored. , and the results are shown in Table 2.

[0051] Table 2 Effect of waste heat boiler fly ash and bag fly ash on fly ash properties

[0052]

[0053]

[0054] It can be seen from Table 2 that after the bag fly ash is mixed with the waste heat boiler fly ash, the alkalinity will decrease significantly, and the heavy metal leaching concentration of the mixed ash will change significantly; this is because the index value of the bag fly ash fluctuates, and generally deviates Alkaline, while the Index value of waste heat boiler fly ash is relatively stable and slightly acidic, so the Index value will change after mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com