Soft measurement method of blast furnace gas generation

A blast furnace gas generation technology, applied in the field of soft measurement, can solve problems such as unbalanced blast furnace gas pipeline network, inaccurate gas measurement, inconsistent measurement values, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

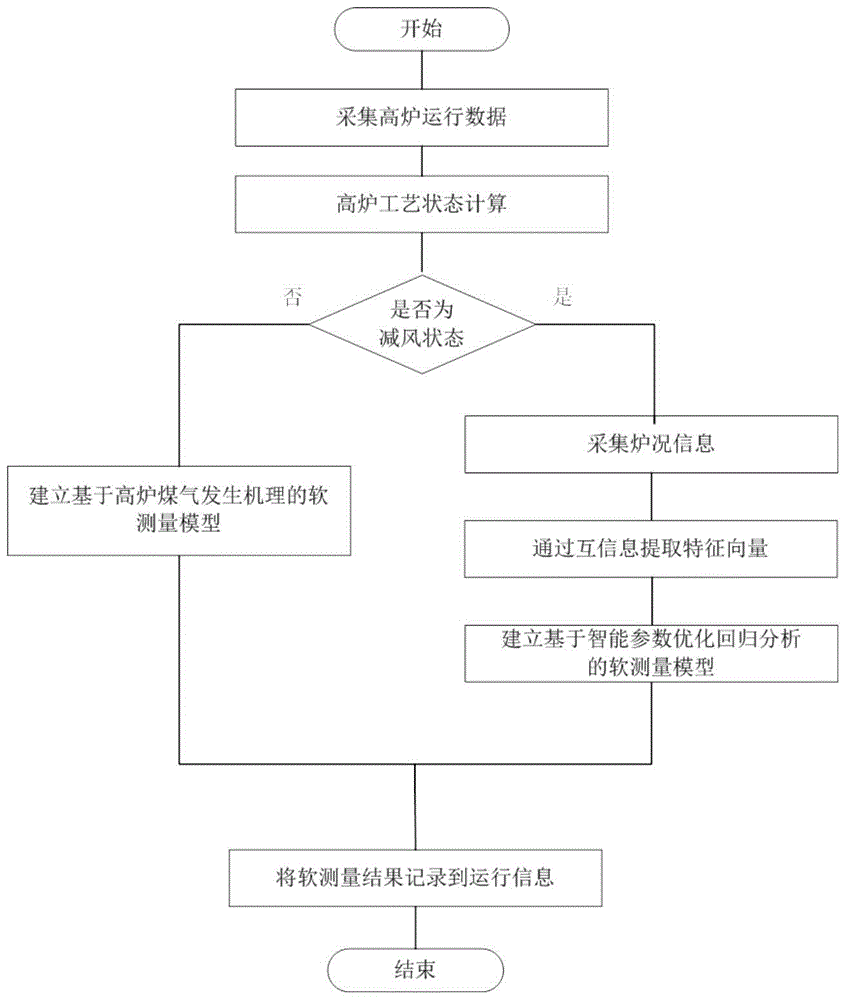

[0075] see figure 1 , figure 2 and image 3 , the present invention provides a method for soft measurement of blast furnace gas generation, comprising the following three steps:

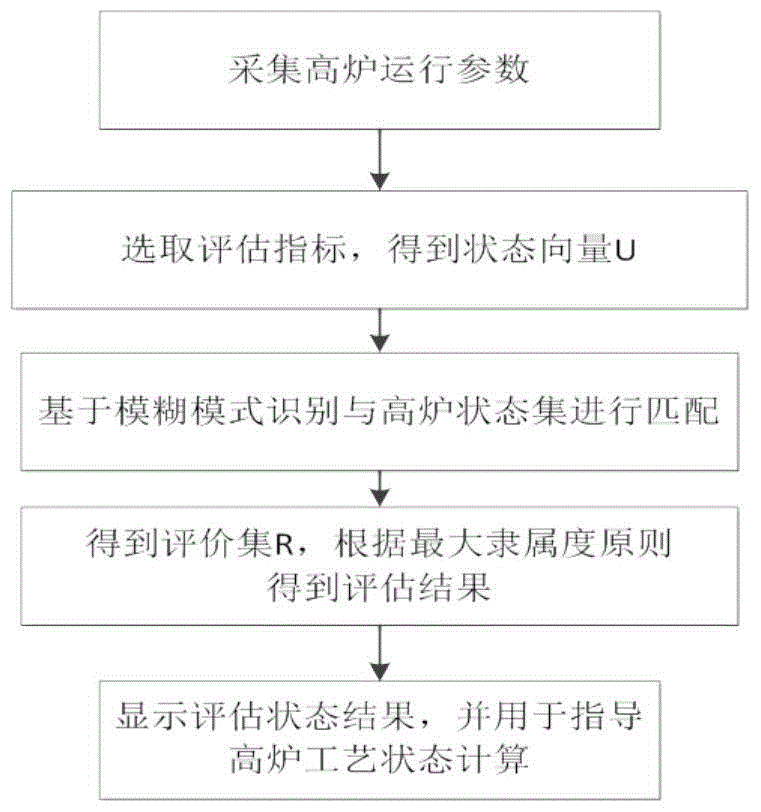

[0076] (1) Blast furnace process state calculation

[0077] Divide the blast furnace process status into three categories: shutdown, wind reduction, and normal, collect blast furnace operation history data from the energy management and control system, select evaluation indicators that characterize blast furnace operation status, establish a blast furnace status calculation model based on fuzzy pattern recognition, and calculate blast furnace status. state of the art.

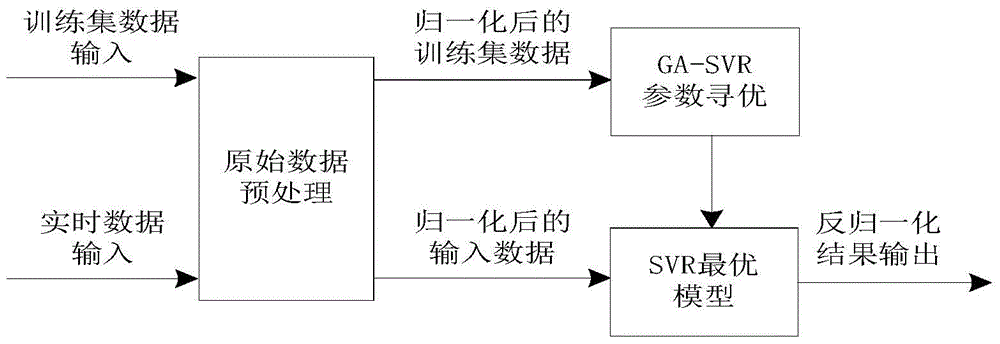

[0078] (2) Soft sensor feature variable selection of blast furnace gas generation

[0079] Select the indicators that affect the amount of blast furnace gas generation, collect various indicators and historical operation data of blast furnace gas generation from the energy management and control system as modeling samples, perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com