A modified carbon anode and its preparation method

A carbon anode and modification technology, applied in the field of anode development of aluminum electrolytic cells, can solve the problems of high operating cost and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

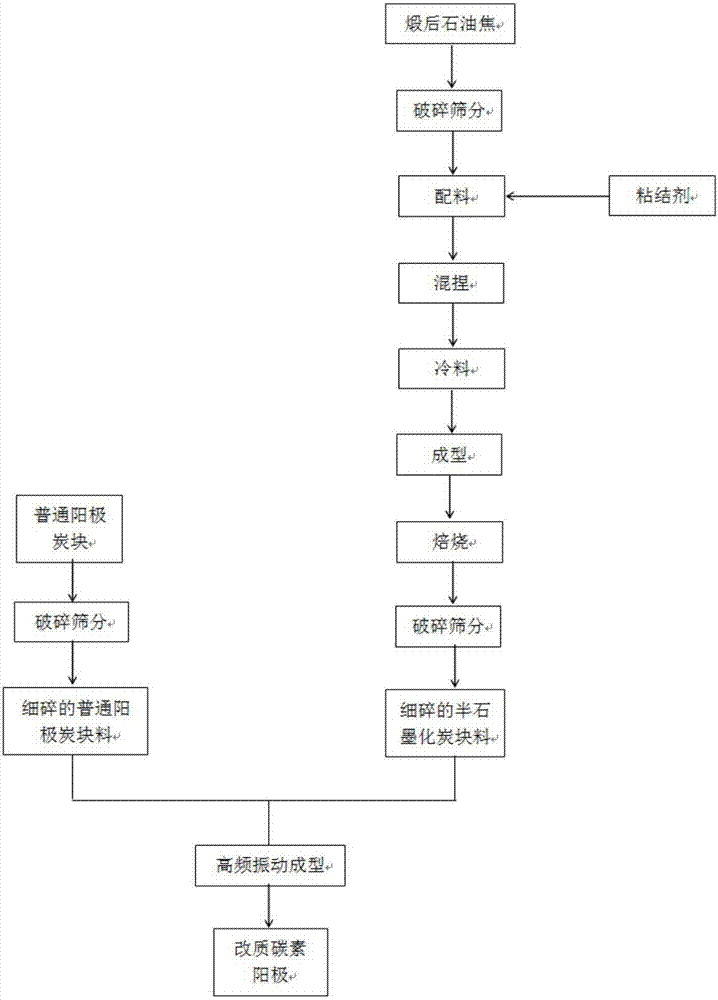

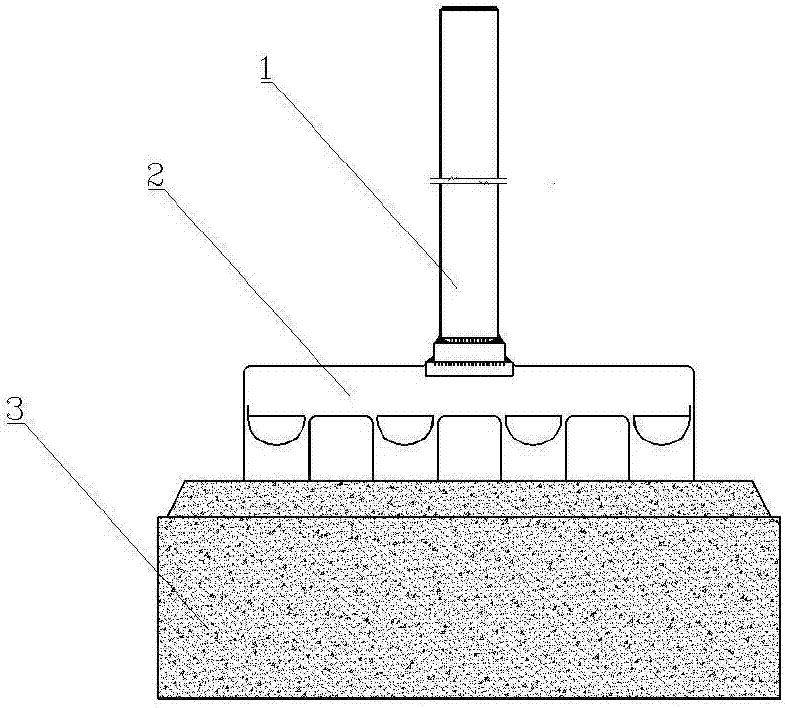

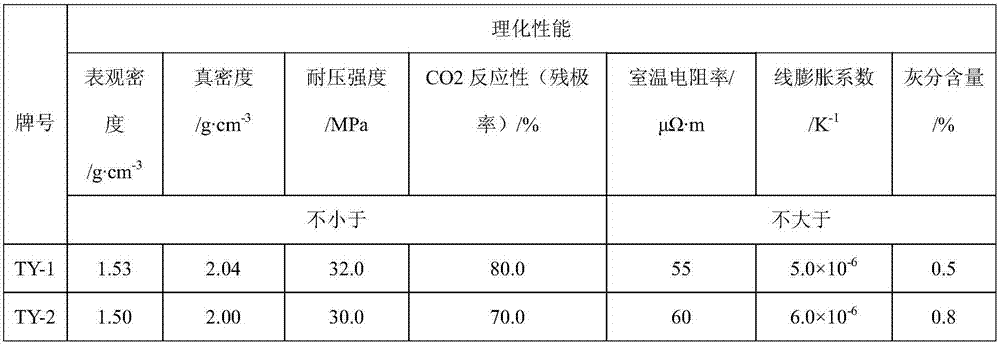

[0030] according to figure 2 The designed structure, according to figure 1 The designed process operates:

[0031] The specific operation includes the separate processing of the modified anode raw material semi-graphite carbon block, and then the semi-graphite carbon block and ordinary carbon block are crushed and screened to a suitable particle size, and the binder is added in proportion, mixed evenly and then added In the vibrating unit, it is processed into a complete anode by high-frequency vibration (vibration frequency is 50Hz), and then assembled with the anode steel claw 2 and the anode guide rod 1. The preparation method of the semi-graphitic carbon particles includes crushing, sieving, batching, kneading, vibration molding, roasting, crushing and sieving.

[0032] In this embodiment, the solid carbon source used to prepare semi-graphitic carbon particles can be selected from calcined petroleum coke, semi-graphitic petroleum coke, and artificial graphite; the binde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap