Vane pumps for injection molding machines

A vane pump and vane technology, which is applied to mechanical equipment, rotary piston machines, pumps, etc., can solve the problems of impermissible vane reversal, complex structure of vane pump, and impact on service life, and achieve increased continuity and small frictional resistance , the effect of effective unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

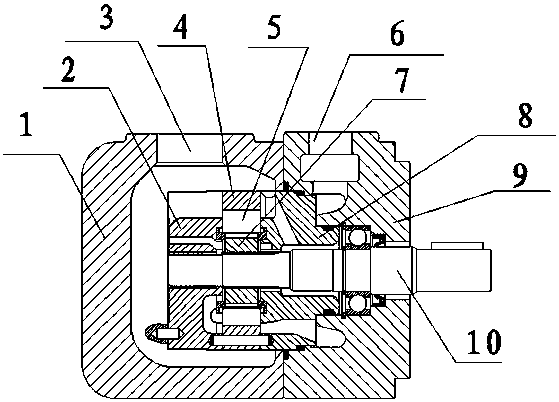

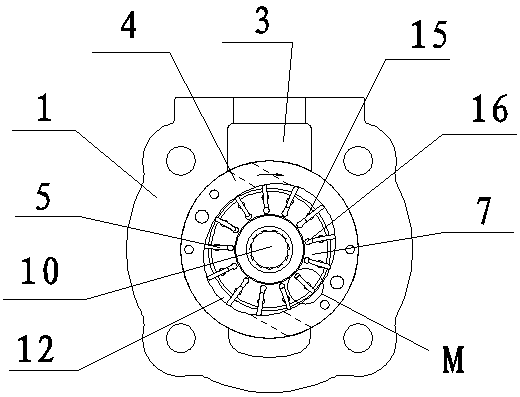

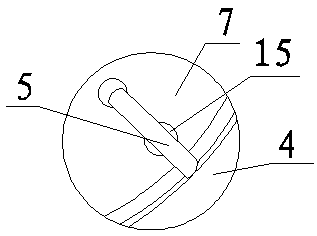

[0038] Such as figure 1 , figure 2 , image 3 As shown, a vane pump suitable for injection molding machines includes a pump body, a pump core and a transmission shaft 10 located in the pump body. The pump body includes a front housing 1 and a rear housing 9 located on the left and right sides, the front housing 1 is provided with an oil suction port 3 , and the rear housing 9 is provided with an oil pressure port 6 . The pump core includes a rotor 7 which is located on the transmission shaft 10 and rotates synchronously with the transmission shaft 10. Thirteen blade grooves 16 are provided on the rotor 7, and blades 5 are inserted in the blade grooves 16. The groove walls on the left and right sides of the blade grooves Each has a lubricating oil hole 15 on it. The lubricating oil hole 15 is a semicircular hole, and the lubricating oil hole 15 is roughly opened in the middle of the blade groove 16 , close to the outer edge of the rotor 7 .

[0039] The stator 4 is sleeved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com