High-temperature-resistant double-layer feeding system

A feeding system and high-temperature-resistant technology, which is applied in the direction of drying solid materials, lighting and heating equipment, drying, etc., can solve the problems of low ignition point, safety accidents, easy to burn, etc., and achieve a simple structure, reasonable design, and completely practical structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

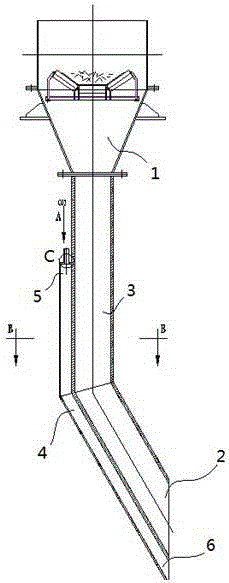

[0015] An explosion-proof high-temperature-resistant double-layer unloading chute, including an unloading chute (3) provided with a double-layer bottom plate of an inlet (1) and an outlet (2), and the unloading chute (3) is also provided with a Import the raw material into the dryer (3) Flame retardant device for deflagration.

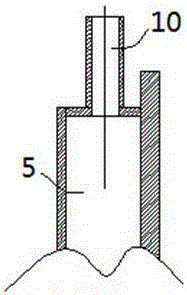

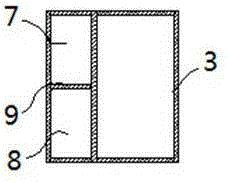

[0016] The flame retardant device includes a flame retardant channel (4) fixed on the outer wall of the discharge chute (3) for venting explosion-proof gas. The flame retardant channel (4) is provided with an air inlet (5) and an air outlet (6), and the air outlet ( 6) Communicating with the above-mentioned outlet (2), the flame-retardant channel (4) is also provided with a partition (9) for dividing the flame-resistant channel (4) into the first channel (7) and the second channel (8) ); the air outlet (5) is also provided with a cylindrical air port (10) for matching with the ventilation equipment, and the cylindrical air port (10) is also communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com