Bridge fault detection device

A technology for fault detection and bridges, which is used in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., and can solve problems such as low bridge detection efficiency and hidden safety hazards for inspectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

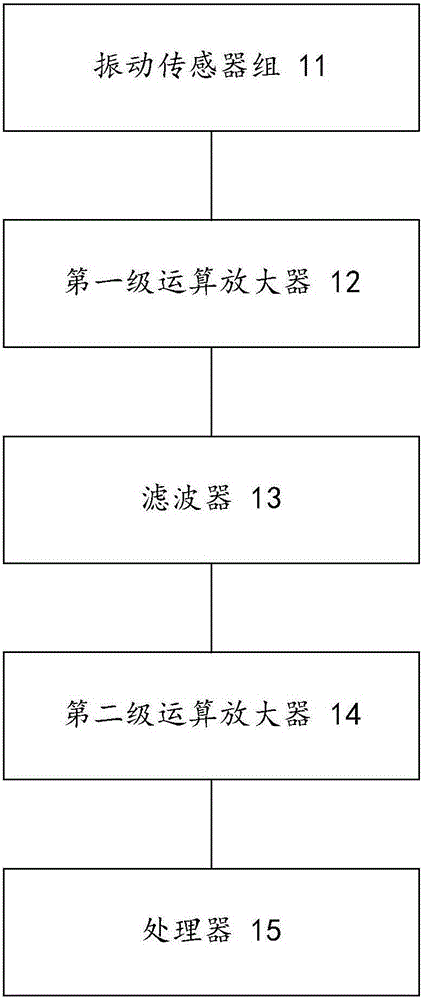

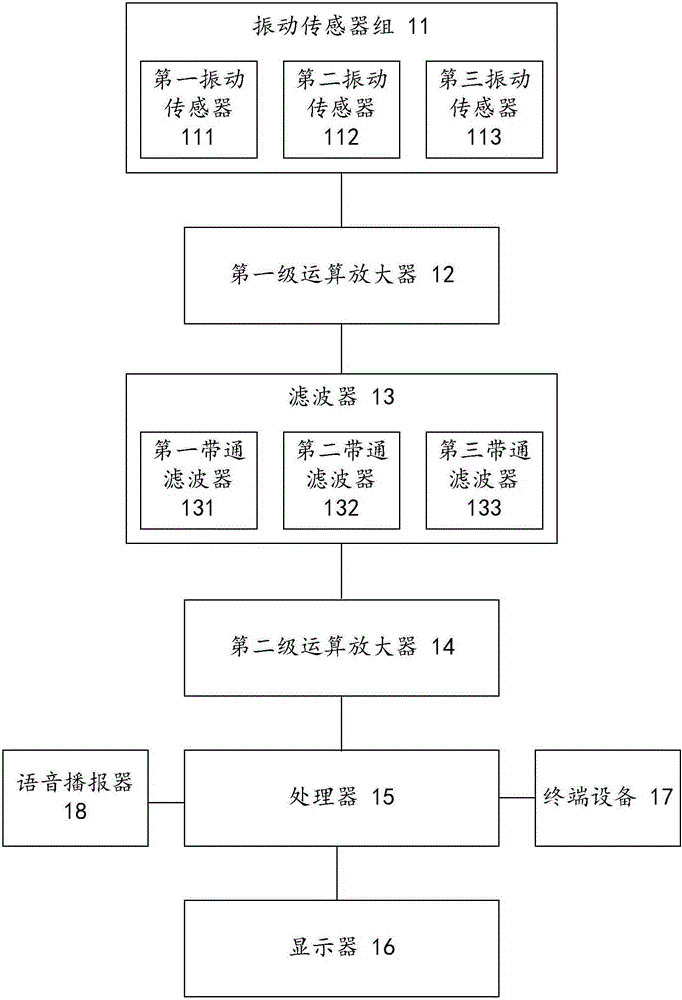

[0028] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] The internal latent faults of the bridge are often accompanied by vibration (mainly generated by vehicles, pedestrians, etc. when passing the bridge). Breakage of internal wooden support components, etc.

[0030] The vibrations caused by different vibration sources correspond to different frequency spectrum ranges, such as:

[0031] The vibration spectrum range caused by the loosening of connecting parts such as screws inside the bridge may be concentrated in the range of 2kHz to 10kHz, and the range of the vibration spectrum caused by the falling of connecting parts such as screws inside the bridge is mainly concentrated in the range of 6kHz to 10kHz. The vibration intensity caused by loosening or falling can reach, for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com