The method of judging the plastic index of materials in rapid deformation by using dwtt test

A plastic index, fast technology, applied in the field of machining, to achieve the effect of convenient use and low implementation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

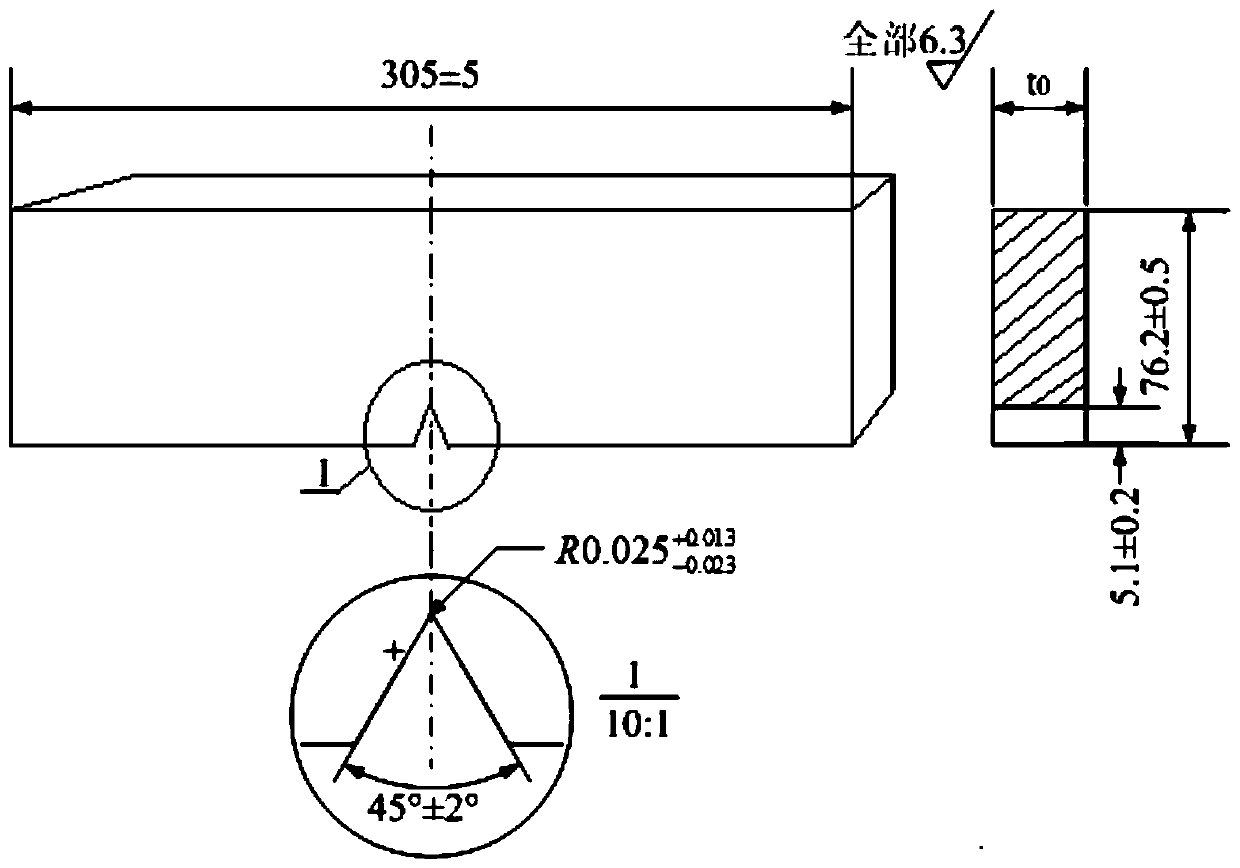

[0029] The method described in this embodiment adopts the DWTT test to evaluate the material to obtain the method of plastic index when rapidly deforming, and the method is realized according to the following steps:

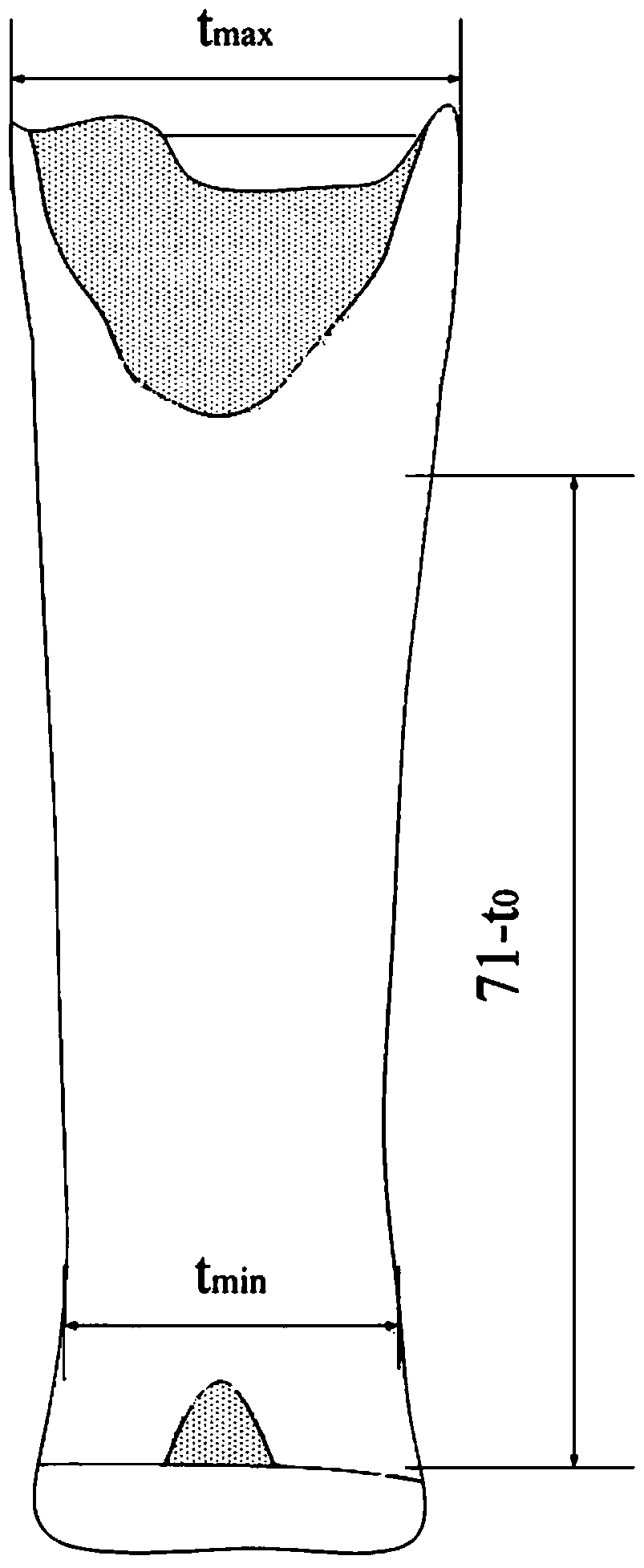

[0030] S1, first obtain the original thickness t of the sample to be subjected to the DWTT test 0 , according to the formula (1) to calculate from the notch root of the sample to the hammering edge minus a sample wall thickness t 0 The original area S of the assessment area 0 ;

[0031] S 0 = t 0 ×(71-t 0 ) (1);

[0032] S2, conduct the DWTT test, measure and record the minimum thickness t of the specimen fracture min and the maximum fracture thickness t max , and the envelope area S of the fracture contour in the assessment area;

[0033] S3, calculating the plasticity index of the sample during rapid deformation; the plasticity index includes: narrowing rate τ, widening rate β, deformation rate λ and area reduction rate δ.

[0034] Calculate the narrow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com