Multi-field coupled low permeability coal seam hydraulic fracturing simulation test method

A technology of hydraulic fracturing and simulation test, applied in the field of hydraulic fracturing, can solve problems such as research methods proposed for hydraulic fracturing of low-permeability coal seams without multi-field coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

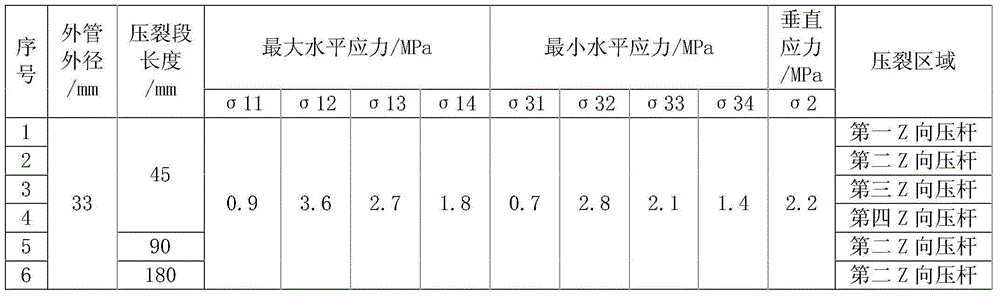

Examples

Embodiment 1

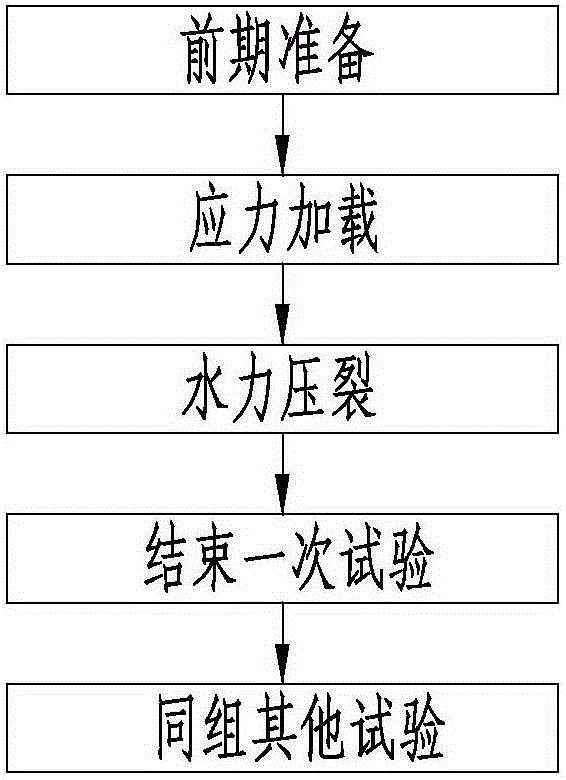

[0026] Such as figure 1 Shown, the present invention comprises the following steps::

[0027] Step 1. Preliminary preparation

[0028] 1a) Mix the prepared coal powder evenly according to a certain particle size ratio, and add a certain binder;

[0029] 1b) During the forming process of the coal rock formation in the test piece box, the sensor and the outer pipe are installed at the same time; the structure of the test piece box and the outer pipe is the same as the structure of the test piece box disclosed in the invention patent with the application number "201310025093.9". I won't go into details here. The outer diameter of the outer tube is 33mm;

[0030] 1c) Seal the test piece box, and connect the sensor wiring to the computer;

[0031] 1d) Place the test piece box in the loading system, then assemble the inner pipe in the outer pipe, and use the inner pipe's drainage area as the fracturing area; the structure of the inner pipe is the same as that in the invention pa...

Embodiment 2

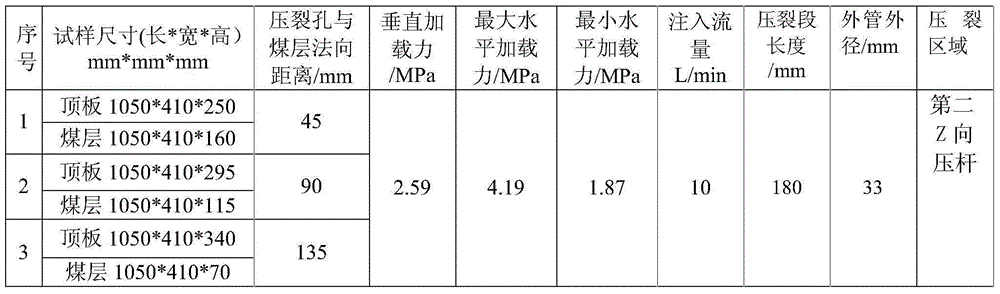

[0045] Such as figure 1 As shown, in the coal seam forming process of step one, the coal seam is simulated with pressed briquettes, the roof is simulated with cement or gypsum pouring and other similar materials, and the outer pipe is pre-embedded and installed in the roof; and in the same group of steps five During the test, the normal distance between the outer pipe and the coal seam was changed. Other steps in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

[0046] Table 2: Virtual reservoir hydraulic fracturing simulation test scheme

[0047]

[0048] For low-permeability and soft coal seams, the appropriate distance for roof fracturing of low-permeability and soft coal seams is studied by changing the normal distance between the fracturing holes and the coal seam by carrying out multiple test programs shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com