Substrate, making method of substrate and display device adopting substrate

A manufacturing method and a technology of a substrate, which are applied to instruments, electrical digital data processing, and the input/output process of data processing, etc., can solve problems such as increasing the width of substrate grounding traces, easy peeling of grounding traces, etc., and improve display quality , increase adhesion, reduce the effect of transmission resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

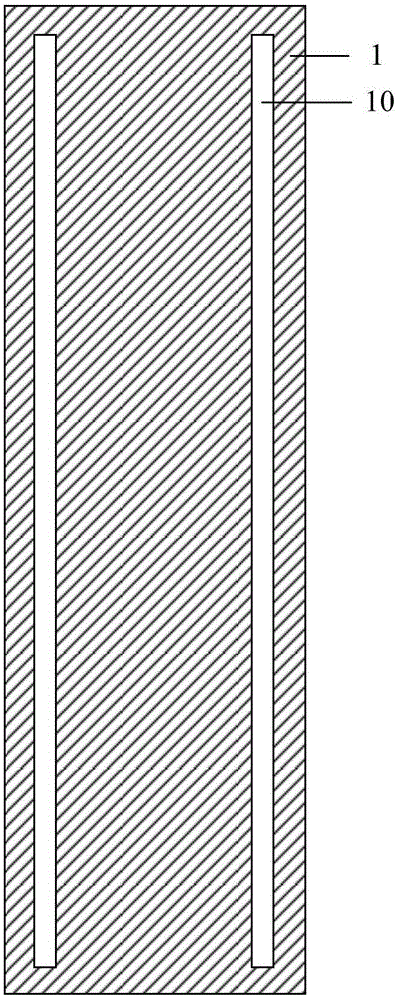

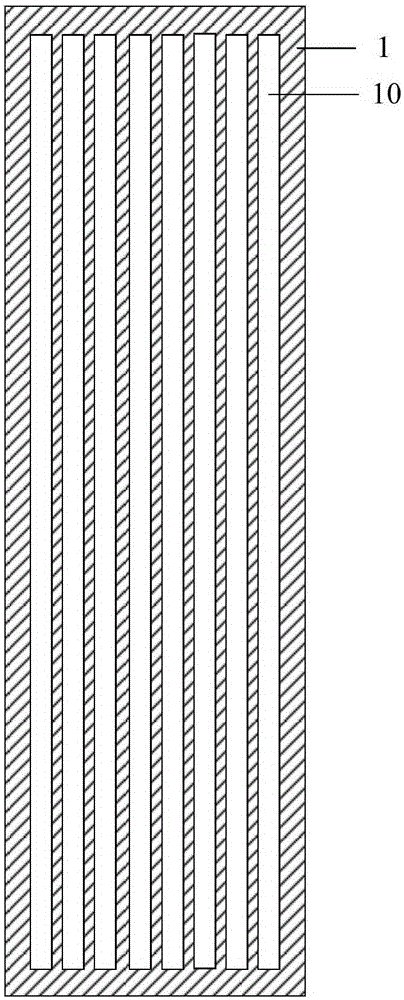

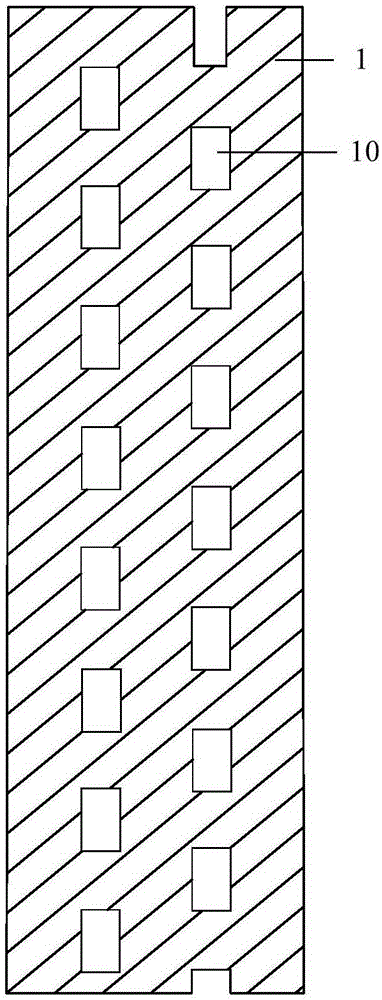

[0020] During the production process of substrates, such as array substrates and color film substrates, static electricity will be introduced. When static electricity with a very high voltage enters the signal line, it will cause electrostatic breakdown of the signal line and form an open circuit, resulting in the inability to transmit the signal and seriously affecting performance of the substrate. In order to avoid the above situation, ground traces are designed on the edge of the substrate. Connect the ground trace to the signal line, or use the tip discharge principle to discharge the static electricity accumulated on the signal line. Low transfer resistance is conducive to the rapid discharge of static electricity from the ground trace. In the prior art, the resistance value of the grounding wire is reduced by increasing the line width of the grounding wire, but this will reduce the adhesion of the grounding wire, and the phenomenon of peeling of the grounding wire is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com