A wiring structure for inductive indium tin oxide layer

An indium tin oxide, wiring structure technology, applied in the input/output process of data processing, instruments, electrical digital data processing and other directions, can solve the problems of low sensitivity, low signal-to-noise ratio, weak graphics display ability, etc. Enhance the overall signal-to-noise ratio, enhance the inter-coupling capacitance, and reduce the effect of attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

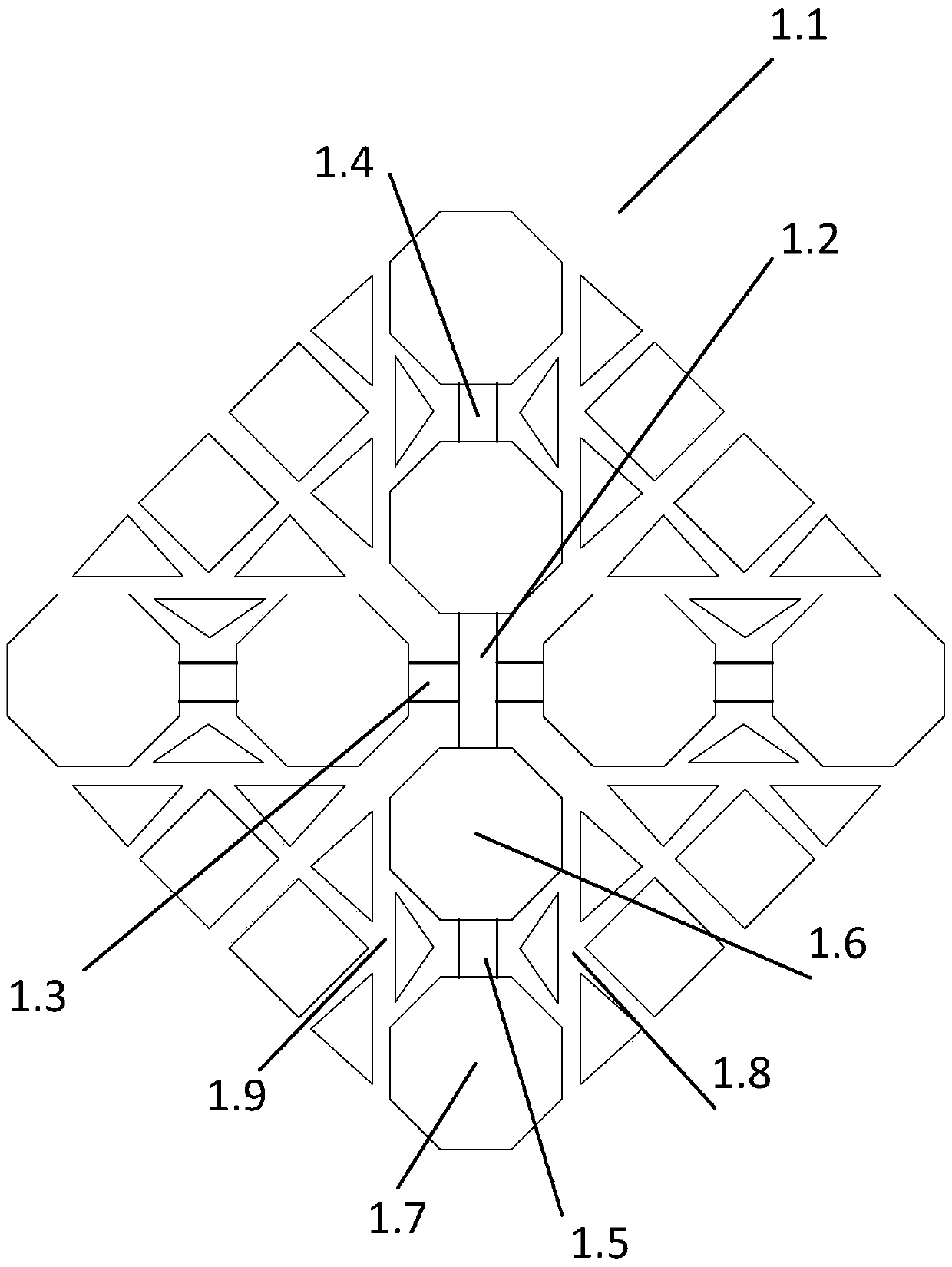

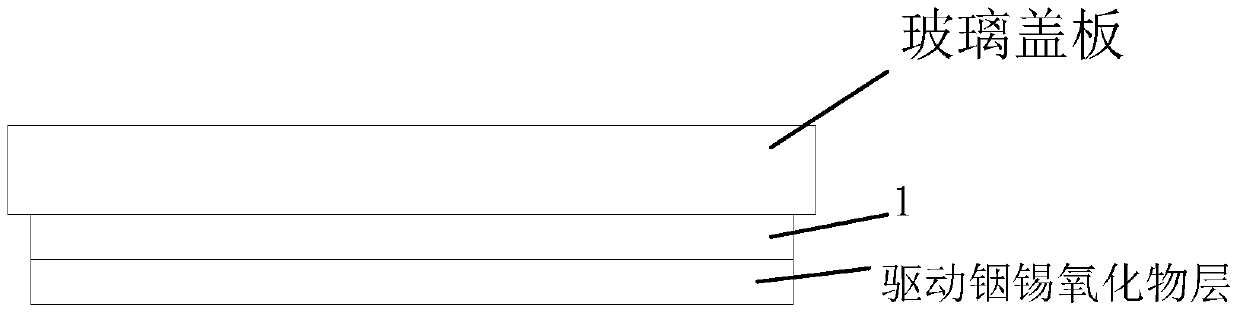

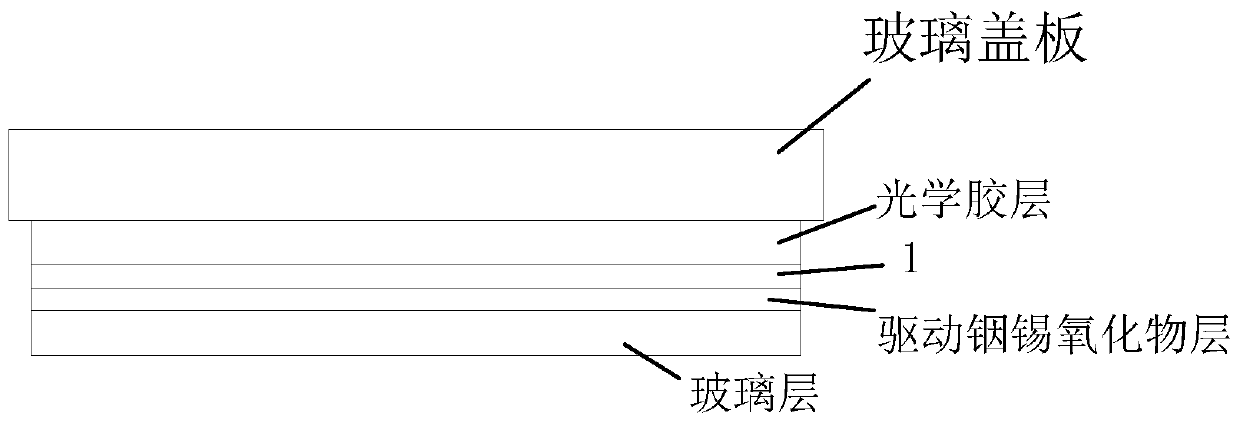

[0016] like figure 1 As shown, the present invention discloses a sensing indium tin oxide layer applied to a touch screen, which includes a plurality of sensing indium tin oxide subunits (1.1) arranged side by side or side by side, wherein each sensing indium tin oxide The subunits (1.1) all include a first touch sensing area (1.2) and a second touch sensing area (1.3) perpendicular to each other; the first touch sensing area (1.2) and the second touch sensing area (1.3) ) each includes a first touch sensing sub-region (1.4) and a second touch sensing sub-region (1.5) connected to each other, and the first touch sensing sub-region (1.4) and the second touch sensing sub-region (1.5 ) are symmetrical to each other.

[0017] In the above technical solution, the first touch sensing sub-region (1.4) and the second touch sensing sub-region (1.5) bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com