Active thermoelectric cooling system for electronic device in severe working conditions

An electronic device, thermoelectric cooling technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problem that the thermoelectric module cannot work efficiently, there is no hot end cooling device, etc., to achieve effective heat dissipation, flexible reliability, and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

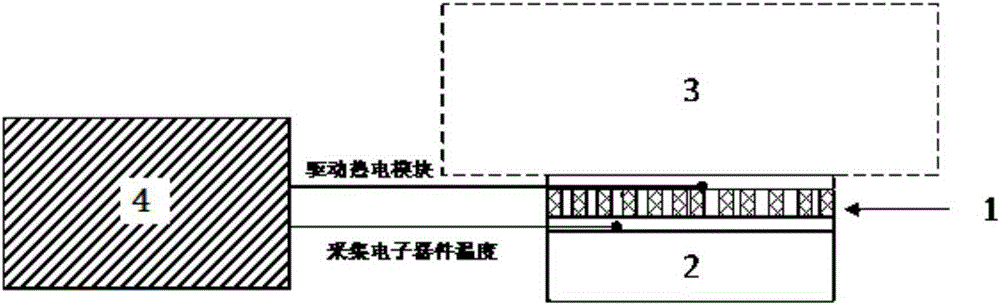

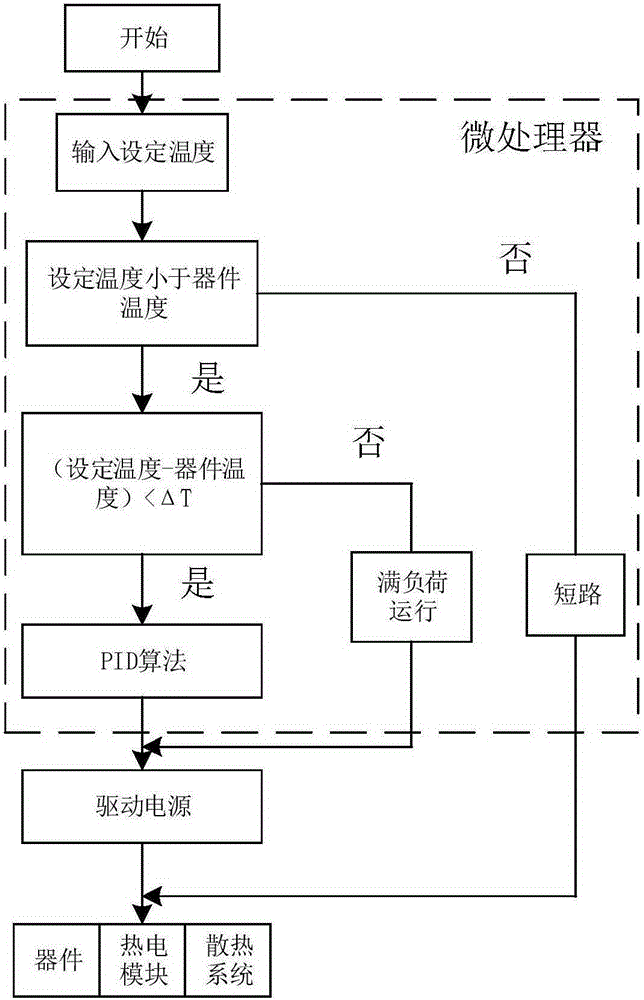

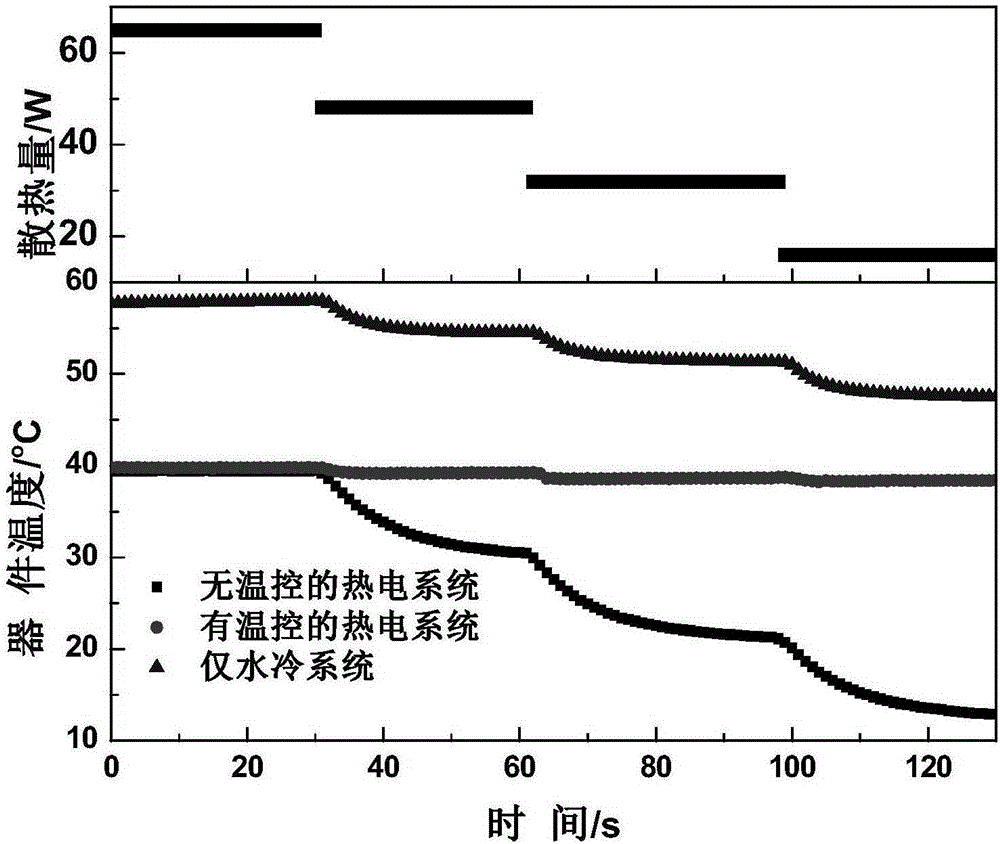

[0040] This embodiment provides an active thermoelectric cooling system for electronic devices under harsh working conditions, including a thermoelectric module assembly, a temperature control assembly, and a passive heat dissipation assembly for dissipating heat from the hot end of the thermoelectric module assembly. Wherein: the cold end of the thermoelectric module assembly (refrigerating sheet) is connected to the heat generating part of the electronic device (the object to be cooled), so as to dissipate heat for the electronic device and realize active cooling of the electronic device. The cold end of the thermoelectric module assembly is close to the heating place of the electronic device, that is, the cooling object; the thermoelectric module assembly and the temperature control assembly are in a loop; The power of the refrigerating sheet of the thermoelectric module assembly is to effectively control the temperature of the electronic device and to lower the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com