Secondary atomization pore-forming method for lithium ion battery

A lithium-ion battery, secondary atomization technology, applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of rebound in thickness of pole pieces, large differences in pores between inner and outer layers, and failure to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

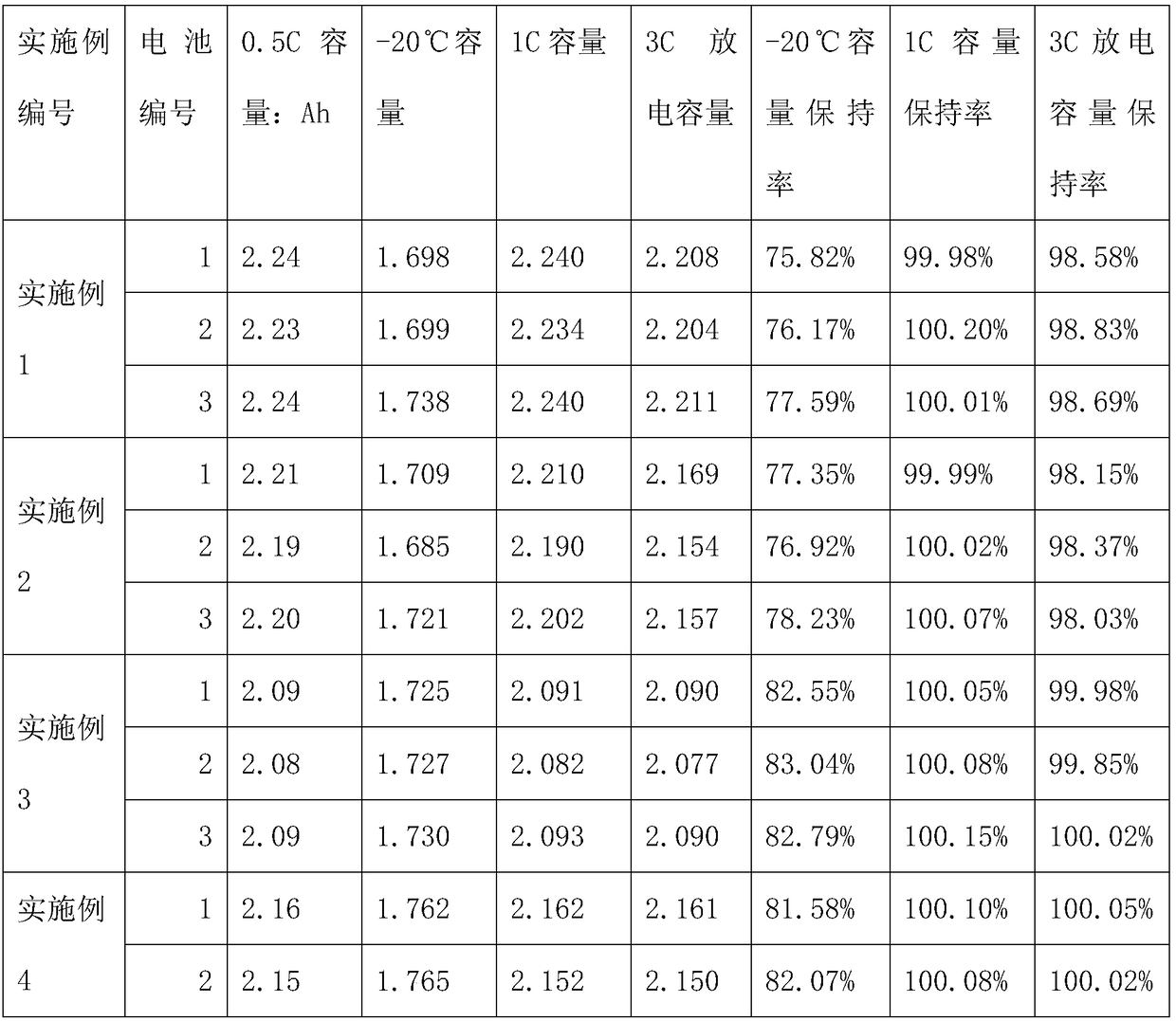

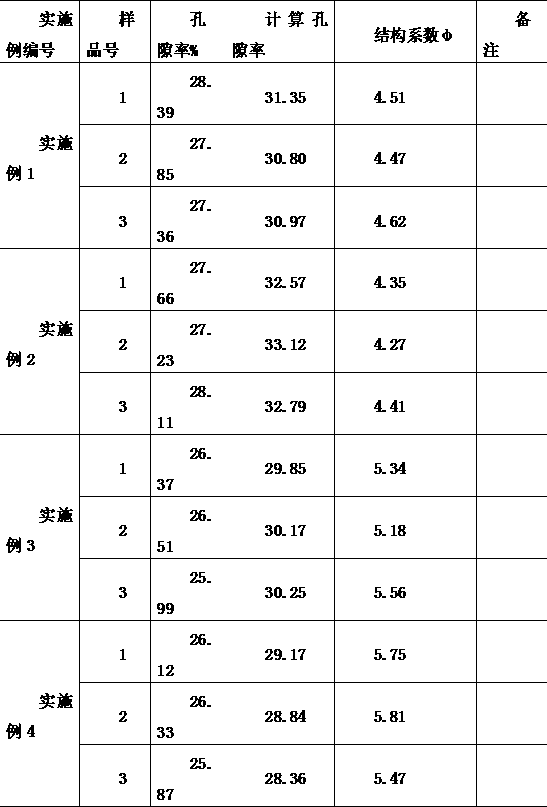

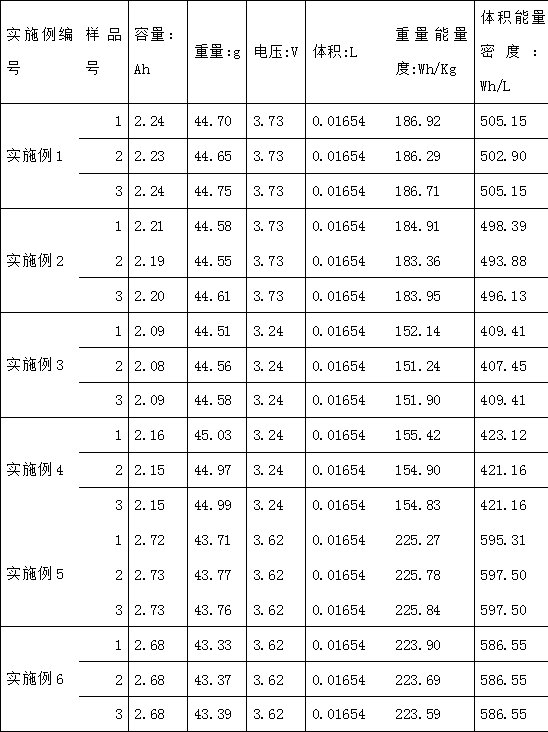

Examples

preparation example Construction

[0038] The present invention has no special requirements for the preparation method of the lithium-ion battery, and it can be carried out with reference to the prior art. Generally speaking, the positive electrode and the negative electrode are wound and separated by a diaphragm to form an electrode group, the electrode group is placed in the battery case, and the electrolytic Liquid, and then sealed, wherein, the method of rolling and sealing is well known to those skilled in the art. The amount of electrolyte used is conventional. The lithium ion battery provided by the present invention can be obtained. Subsequent conventional steps such as aging and chemical formation will not be repeated here.

[0039] The present invention only relates to the improvement of the pole piece processing technology of the prior art lithium-ion secondary battery, so there is no special limitation on other compositions and structures of the lithium-ion secondary battery. For example, there ar...

Embodiment 1

[0041] A secondary atomization pore-forming method for a lithium-ion battery, comprising the following steps:

[0042] S1: Prepare a pore-forming agent solution and a saturated aqueous solution of ammonium bicarbonate;

[0043] S2: The spray box and fast oven at the tail of the coating machine, the interior of the spray box is filled with atomized pore-forming agent solution, the atomization pressure is 1KPa, and the atomization temperature is 100°C;

[0044] S3: Evenly coat the prepared negative electrode graphite slurry on the current collector substrate, and after drying, pass through the spray box and its oven at a speed of 0.5 m / s to ensure that the electrode piece accepts the atomization time for 30 seconds. The baking time of the oven is subject to drying;

[0045] S4: Harvest the baked and dried pole pieces into coils, and roll them into rolls according to the normal process through a roller press, with a compacted density of 1.68g / cm 3 ;

[0046] S5: Pass the rolle...

Embodiment 2

[0051] A secondary atomization pore-forming method for a lithium-ion battery, comprising the following steps:

[0052] S1: Prepare a pore-forming agent solution, ethanol solution of p-benzenesulfonyl hydrazide;

[0053] S2: The spray box and fast oven at the tail of the coating machine, the interior of the spray box is filled with atomized pore-forming agent solution, the atomization pressure is 20KPa, and the atomization temperature is 80°C;

[0054] S3: Evenly coat the prepared negative electrode graphite slurry on the current collector substrate, and after drying, pass through the spray box and its oven at a speed of 2 m / s to ensure that the electrode piece accepts the atomization time for 180 seconds. The baking time of the oven is subject to drying;

[0055] S4: Harvest the baked and dried pole piece into a roll material, and roll it through a roller press according to the normal process, with a compacted density of 1.6g / cm3;

[0056] S5: Pass the rolled pole piece thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com