Automatic transmission for vehicles

An automatic transmission and vehicle technology, which is applied to vehicle gearboxes, vehicle components, transmission components, etc., can solve the problems of inability to expand the transmission range and inability to ensure the inter-stage ratio, so as to improve vehicle loadability, realize engine noise, and reduce fuel consumption. The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

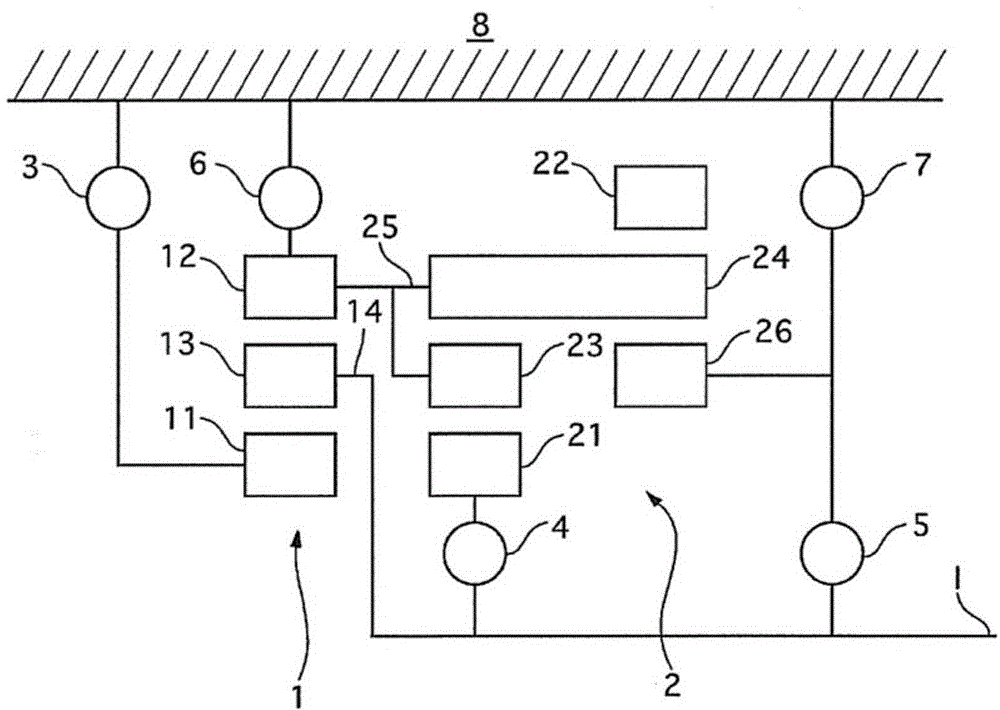

[0036] First, the overall structure of the vehicular automatic transmission according to Embodiment 1 will be described.

[0037] The vehicular automatic transmission of the first embodiment is suitable for a so-called transverse-engine vehicle, a front-wheel-drive vehicle with a front-mounted engine or a rear-wheel-drive vehicle with a rear-mounted engine.

[0038] figure 1 The outline of the vehicular automatic transmission of the first embodiment is shown. also, figure 1 In , the upper half is drawn from the central axis (the axis passing through the central axis of the input shaft I), and the lower half is omitted. also, Figure 10 A cross section of the vehicle automatic transmission of Example 1 is shown.

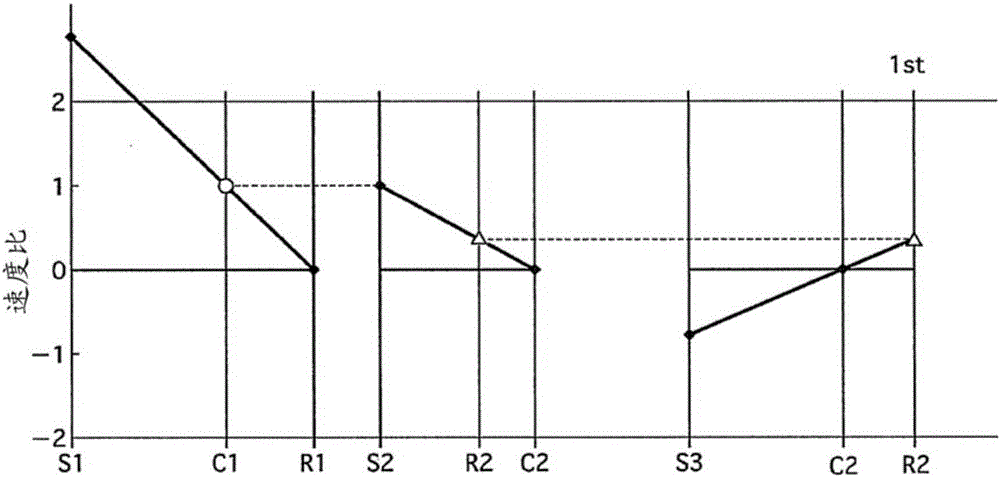

[0039] As shown in this figure, the automatic transmission for a vehicle according to Embodiment 1 includes: an input shaft I, an output member O ( Figure 10 The transmission gear 50 shown is always connected with the second ring gear 22), the first planetary ge...

Embodiment 2

[0106] Next, an automatic transmission according to Embodiment 2 of the present invention will be described below.

[0107] In addition, the same code|symbol is attached|subjected to the same component as Example 1, and their description is abbreviate|omitted.

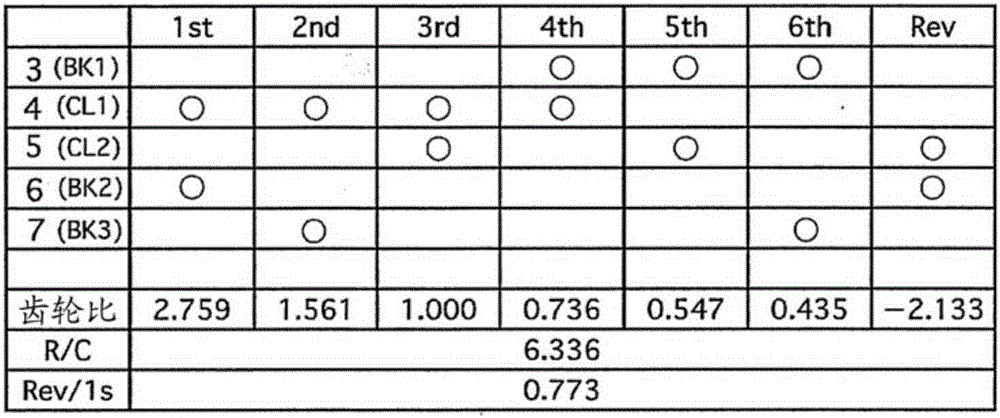

[0108] In the automatic transmission of Embodiment 2, only the first planetary gear set 1 is changed from the single-pinion type planetary gear of Embodiment 1 to a double-pinion type planetary gear set. However, along with this, the values of gear ratio, shift range (R / C value), and reverse gear ratio / first gear ratio (Rev / 1st) are also changed.

[0109] In addition, in the same figure, the position of the second brake 6 is changed to move between the second ring gear 22 and the third brake 7, but the action of fixing the first ring gear 12 and the second planet carrier 25 remains unchanged.

[0110] That is, the first planetary gear set 1 has: the first sun gear 11, the first ring gear 12, the first inner planetar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com