Micromechanical sensor device and corresponding production method

A sensor device and micro-mechanical technology, which can be used in semiconductor/solid-state device manufacturing, measurement devices, thermoelectric devices with thermal changes in permittivity, etc., and can solve problems such as expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

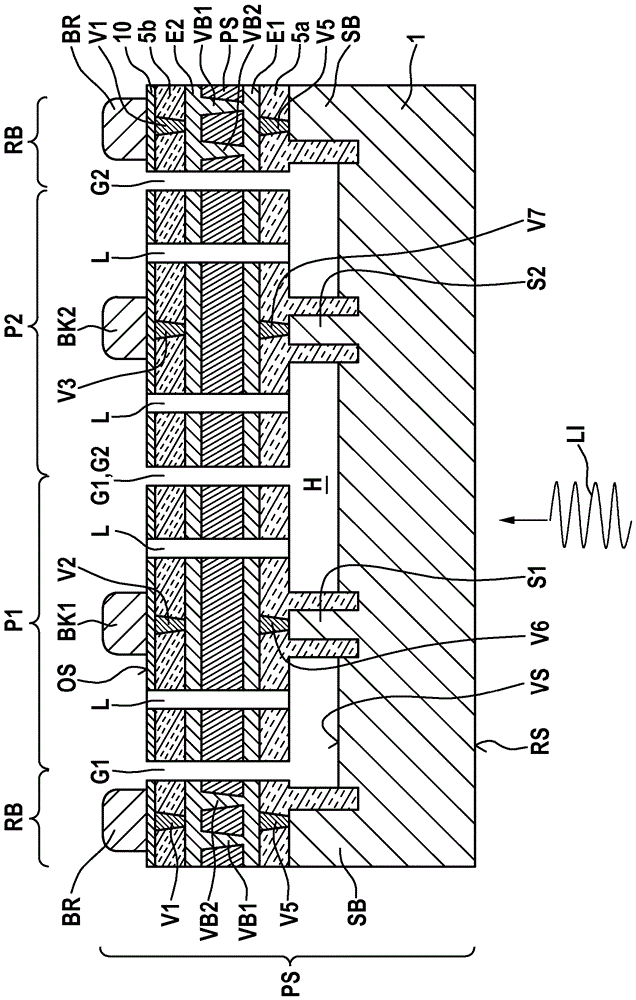

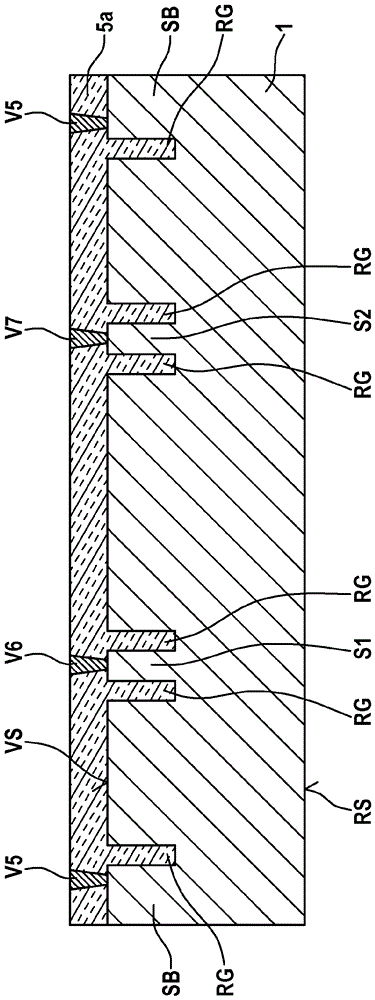

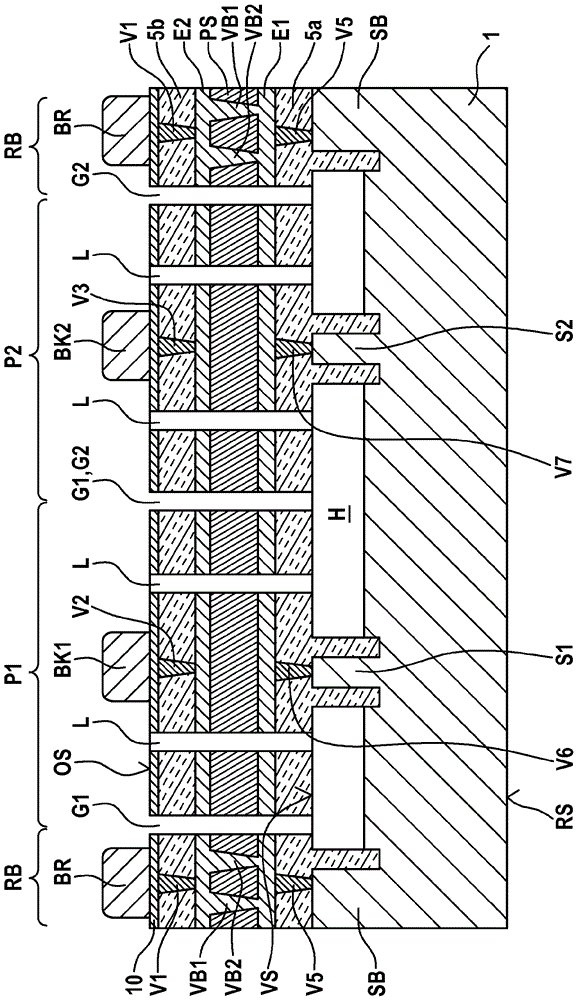

[0025] figure 1 is a schematic cross-sectional view for explaining the micromechanical sensor device according to the first embodiment of the present invention.

[0026] exist figure 1 In , reference numeral 1 denotes a low-resistance silicon substrate having a front side VS and a back side RS. A first post S1 and a second post S2 are formed on the front side VS of the silicon substrate 1 . A surrounding edge wall SB is formed in the edge region RB of the silicon substrate 1 .

[0027] A corresponding sensor element P1 or P2 in the form of a pyroelectric pixel element is formed on the first pillar S1 and the second pillar S2 , wherein the sensor elements P1 , P2 each have a higher thickness than the associated pillar S1 or S2. The lateral extent is large, and a cavity H is provided laterally of the pillar S1 or S2 below the sensor element P1 or P2 .

[0028] The sensor elements P1 , P2 are laterally separated from each other by respective separating grooves G1 , G2 and on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com