Nozzle and water purifier with same

A nozzle and head technology, applied in the field of nozzles, can solve the problems of ineffective removal of membrane silk sediment and dirt, low turbulence intensity, dismantling and maintenance, etc., to ensure water flow and operation stability, and improve turbulence intensity , enhance the effect of scouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

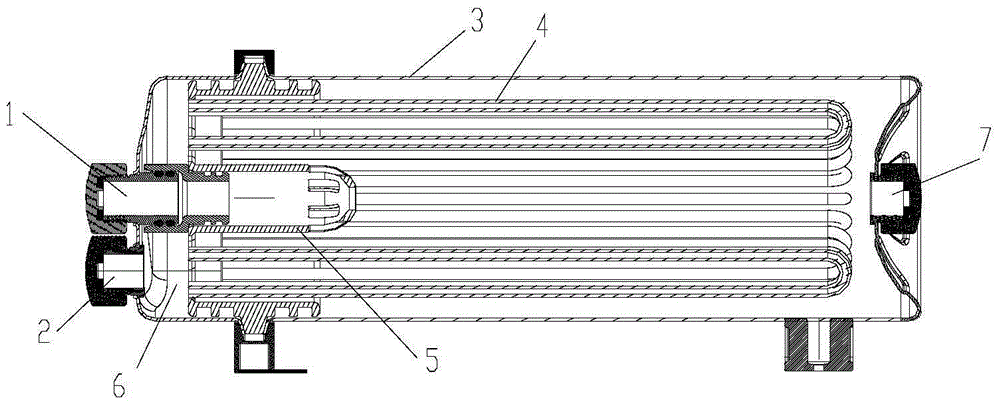

[0036] see first Figure 6-9 , which schematically shows a nozzle according to a first preferred embodiment of the present invention.

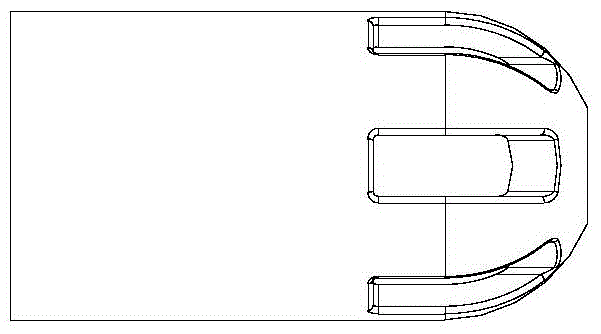

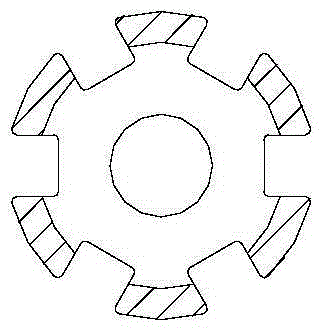

[0037] Described nozzle generally comprises body part 11 and head 12, and the internal flow path of nozzle (see Figure 8 ) extends from the body portion 11 to the head portion 12, and the head portion 12 is provided with an axial outflow channel 13 and a lateral outflow channel 14 (such as 6 in the figure). For example, in this embodiment, the axial outlet channel 13 is preferably coaxial with the nozzle, while the lateral outlet channel 14 is preferably arranged radially. When the nozzle is in operation, fluid such as water enters the inner channel of the nozzle from the main body 11 , flows to the head 12 and then sprays out through the axial outlet channel 13 and each side outlet channel 14 .

[0038] In the prior art (see Figure 2-5 ), the internal channel of the nozzle extends continuously from the body (the cross-sectional area tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com