Feed and discharge robot for pipe connector

A robot and pipe joint technology, applied in the field of robots, can solve the problems that the integrity of the processing process cannot be fully reflected, cannot adapt to the factory production environment, and the operation process is difficult to complete, etc., to achieve simple and light structure design, moderate size, and working mode simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

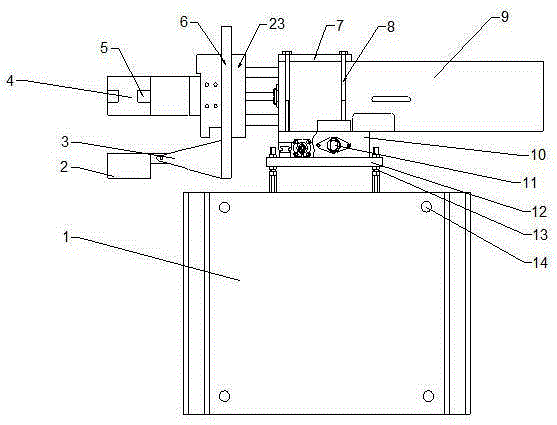

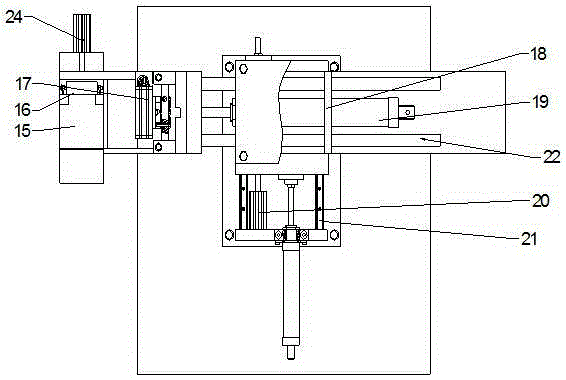

[0025] like figure 1 and figure 2 As shown, the present invention discloses a pipe joint loading and unloading robot, comprising a support base, a pushing device, a feeding device, a slewing mechanism, a manipulator claw and a feeding tray;

[0026] The support base includes a base cabinet 1, support bolts 13 and a support base plate A12; the base cabinet 1 has a column structure, and four support bolts 13 are fixed in the middle of the upper surface; the edge of the support base plate A12 is evenly distributed with four threaded holes for the support bolts 13 to be inserted into. Installed on the upper part of the support bolt 13 and locked; the pushing device includes a pair of guide rails 21 installed on the support base plate A12, a sliding block slidingly matched with the guide rails, a pushing cylinder A20, a baffle plate perpendicular to the support plate, and a baffle plate arranged on the baffle plate push cylinder B11; push cylinder A12 and push cylinder B11 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com