Negative ion window screen film punching method and microporous window screen film

A technology of microporous window screen film and negative ions, which is applied in metal processing, insect control and other directions, can solve the problems of good anti-haze effect, poor anti-haze effect, insufficient air permeability, etc., and achieves low cost, small equipment investment, and improved The effect of machining speed and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

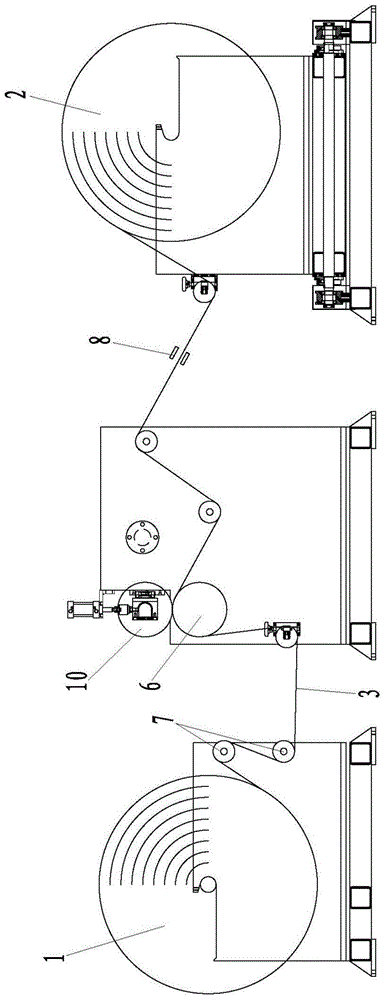

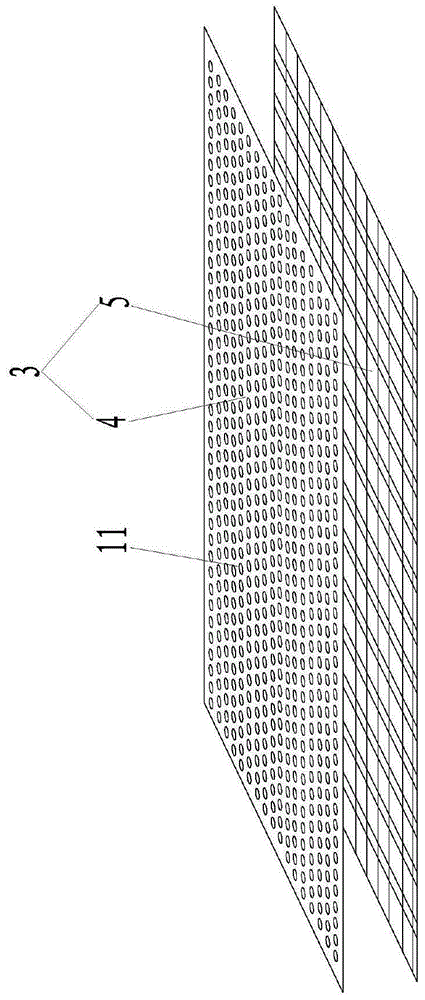

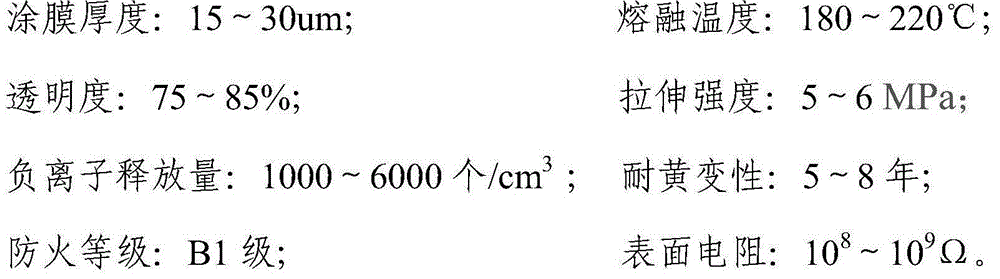

[0025] Anion window screen film punching method of the present invention has used negative ion window screen film punching device, as figure 1 Shown, comprise unwinding machine 1 and winding machine 2, unwinding machine 1 and winding machine 2 are equipped with belt-shaped negative ion window screen film 3, combine figure 2 As shown, the negative ion window screen film 3 is formed by connecting the negative ion film 4 and the common window screen 5, and a dragging pressure roller 6, a plurality of transition rollers 7 and a deviation corrector 8 are arranged between the unwinder 1 and the winder 2, and the negative ion The window screen film 3 passes through a plurality of transi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unwind tension | aaaaa | aaaaa |

| Winding tension | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com