Bonding clump weight for wheel balance

A kind of counterweight and bonding technology, which is applied in the direction of wheel counterweight, rolling resistance optimization, road transportation emission reduction, etc., can solve the problems of troublesome bending operation, difficult to distinguish specifications, and reduced management ability, so as to improve the operation efficiency. , the effect of reducing manufacturing costs and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

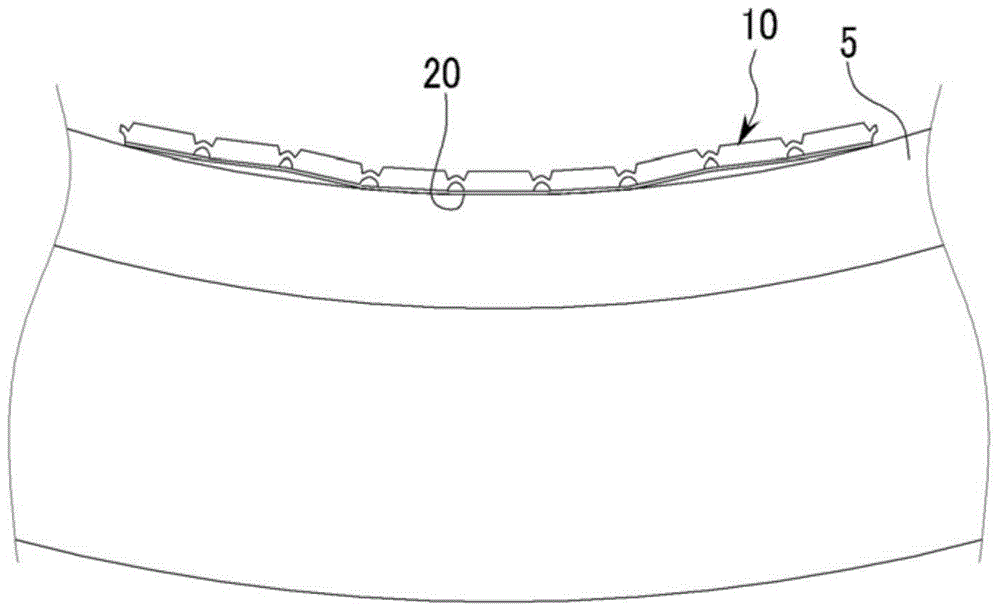

[0023] The bonded wheel balance weight of the present invention has a structure in which the radius of curvature of the center portion of the weight body and the radii of curvature of both ends of the weight body are different from each other so that it can be smoothly applied to tires of various sizes. .

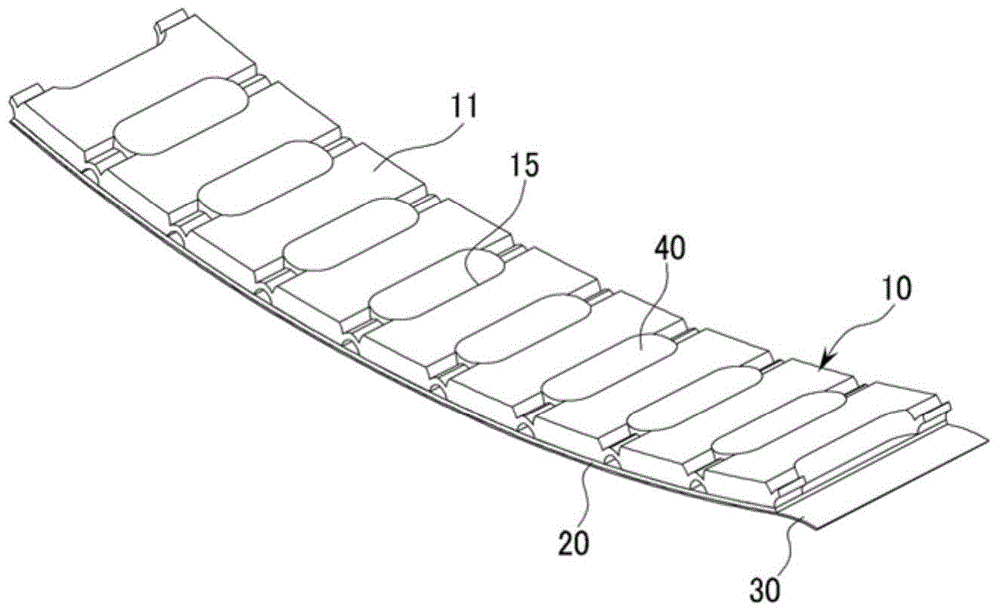

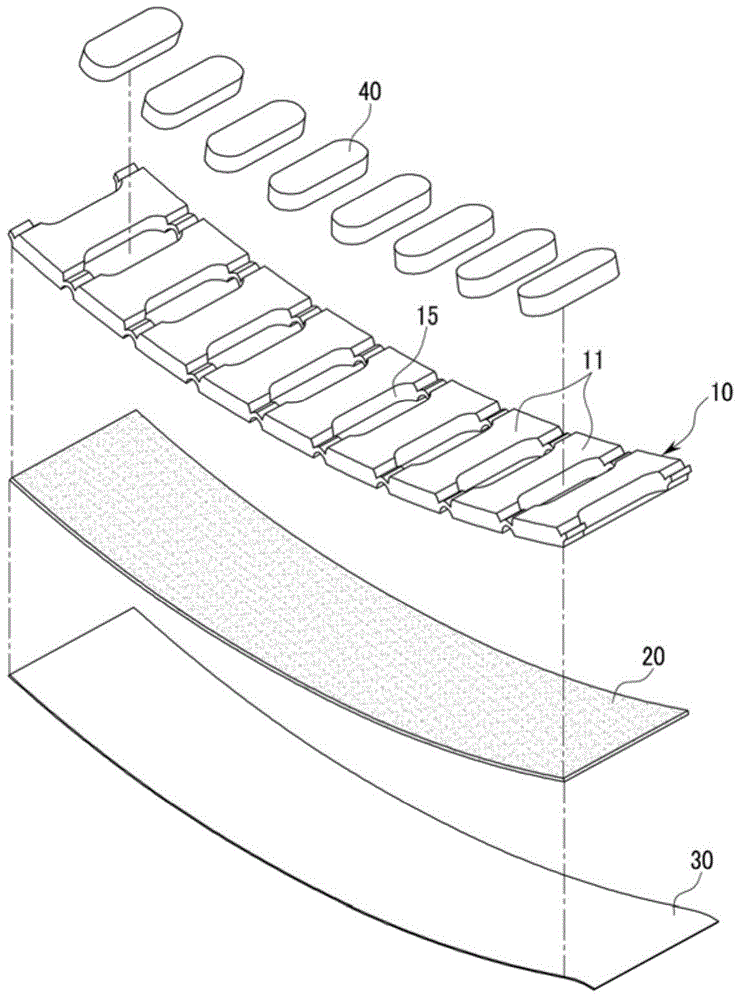

[0024] Below, refer to Figure 1 to Figure 5 , the wheel balancing weight according to the embodiment of the present invention will be described.

[0025] refer to Figure 1 to Figure 5 , the counterweight for wheel balancing according to an embodiment of the present invention includes: a counterweight body 10, which has a structure in which a plurality of unit counterweights 11 are connected to each other in a state of continuous horizontal arrangement, and a bonding portion 20 is arranged on the above-mentioned One side of the counterweight body 10 and the release paper 30 are attached to the above-mentioned bonding part 20 to protect the above-mentioned bonding part 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com