Transformer copper strip edge burr treatment device and method

A processing device and a technology for a transformer are applied in the field of burr removal equipment on the edge of a copper strip of a transformer, which can solve the problems of complicated operation and difficult adjustment, and achieve the effect of excellent processing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

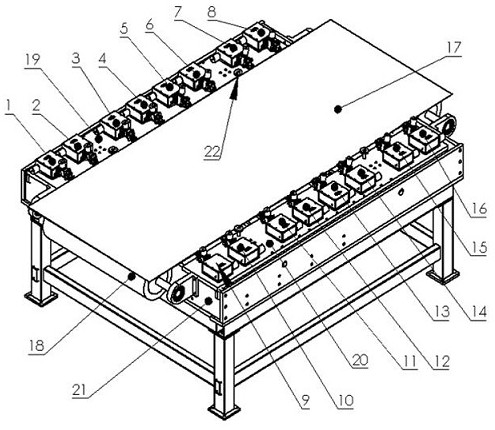

[0035] Example 1, see figure 1, the present invention provides a technical solution: a transformer copper strip edge burr treatment device, including a frame 21, the front and rear ends of the frame 21 are provided with transformer copper strip stabilizing rollers 18, two of the transformer copper strip stabilizing rollers 18 A transformer steel strip 17 is placed between the tops of the frame 21, movable left cutter head mounting plate 19 and right cutter head mounting plate 20 are arranged on both sides of the frame 21, and cutter head mounting plates 19 are arranged on the left side cutter head mounting plate in turn. 45 degrees to the upper left of the assembly 1, 60 degrees to the upper left of the cutter head assembly 2, 30 degrees to the upper left of the cutter head assembly 3, upper left arc of the cutter head assembly 4, 45 degrees to the lower left of the cutter head assembly 5, 60 degrees to the lower left of the cutter head assembly 6. The cutter head assembly is ...

Embodiment 2

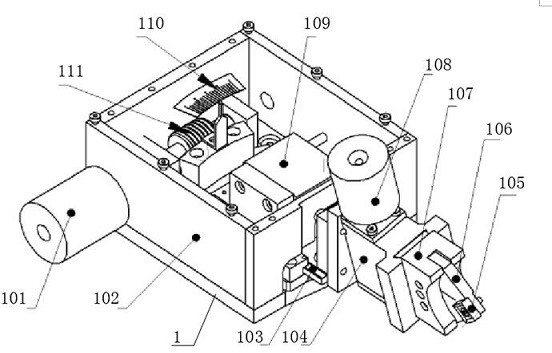

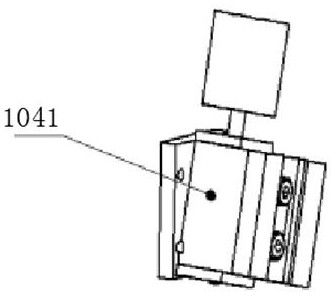

[0036] Example 2, see Figure 2-7 , Cutter head assembly left upper 45 degrees 1, Cutter head assembly left upper 60 degrees 2, Cutter head assembly left upper 30 degrees 3, Cutter head assembly left upper arc 4, Cutter head assembly lower left 45 degrees 5, Cutter head assembly Lower left 60 degrees 6. Cutter head assembly lower left 30 degrees 7. Cutter head assembly lower left arc 8. Cutter head assembly upper right 45 degrees 9. Cutter head assembly upper right 60 degrees 10. Cutter head assembly upper right 30 degrees 11. The upper right arc of the cutter head assembly 12, the lower right of the cutter head assembly 45 degrees 13, the lower right 60 degrees of the cutter head assembly 14, the lower right 30 degrees of the cutter head assembly 15 and the lower right arc 16 of the cutter head assembly There is knife box 102, and a side of knife box 102 is equipped with cutter head rotation adjustment handle 101, and the inner bottom surface of knife box 102 is equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com