Supporting block for independent ship liquid tank

A support block and liquid tank technology, which is applied in ship accessories, ships, load handling devices, etc., can solve the problems of consuming workload and time, large time, insufficient installation accuracy of support blocks, etc., so as to improve the installation accuracy and simplify the leveling process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

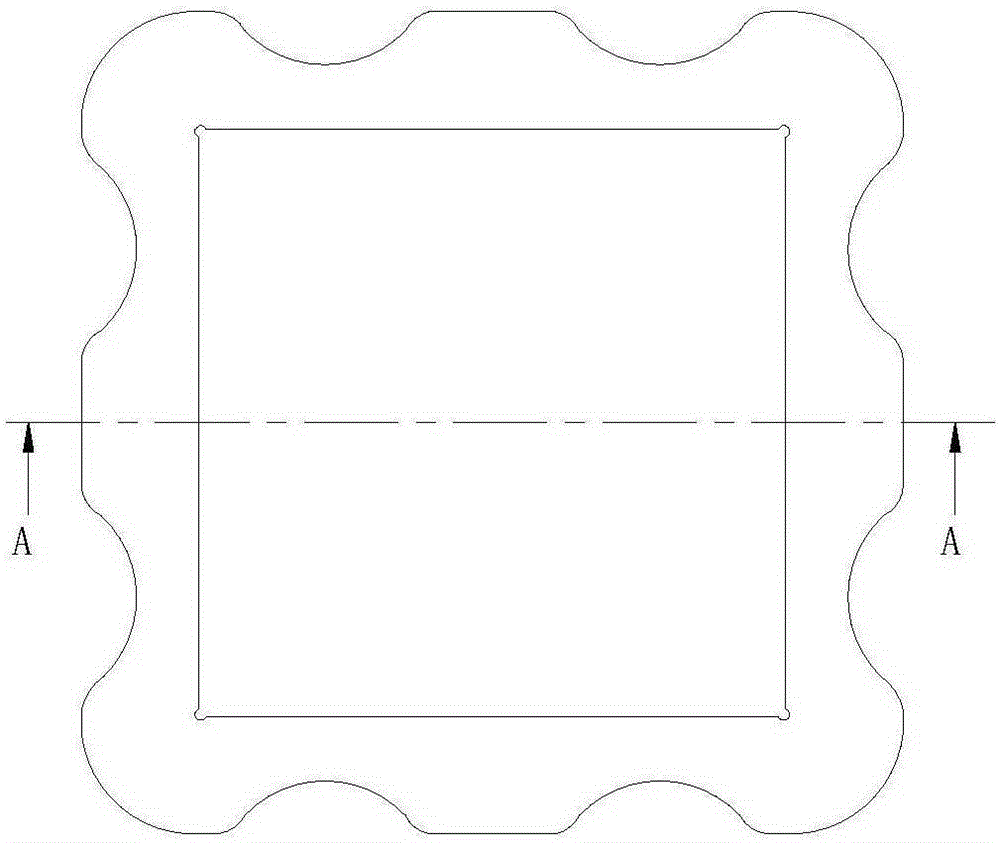

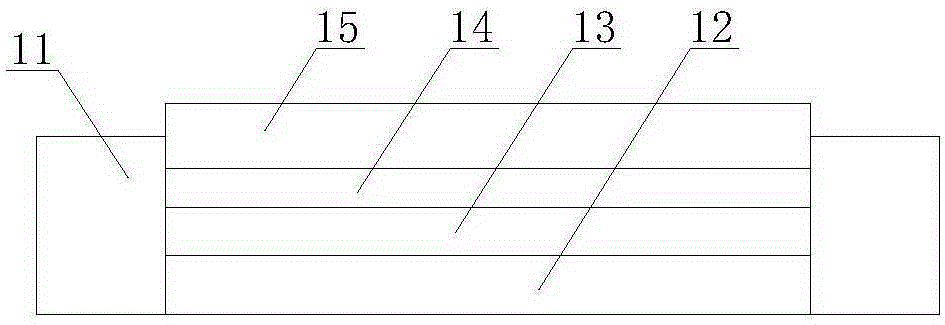

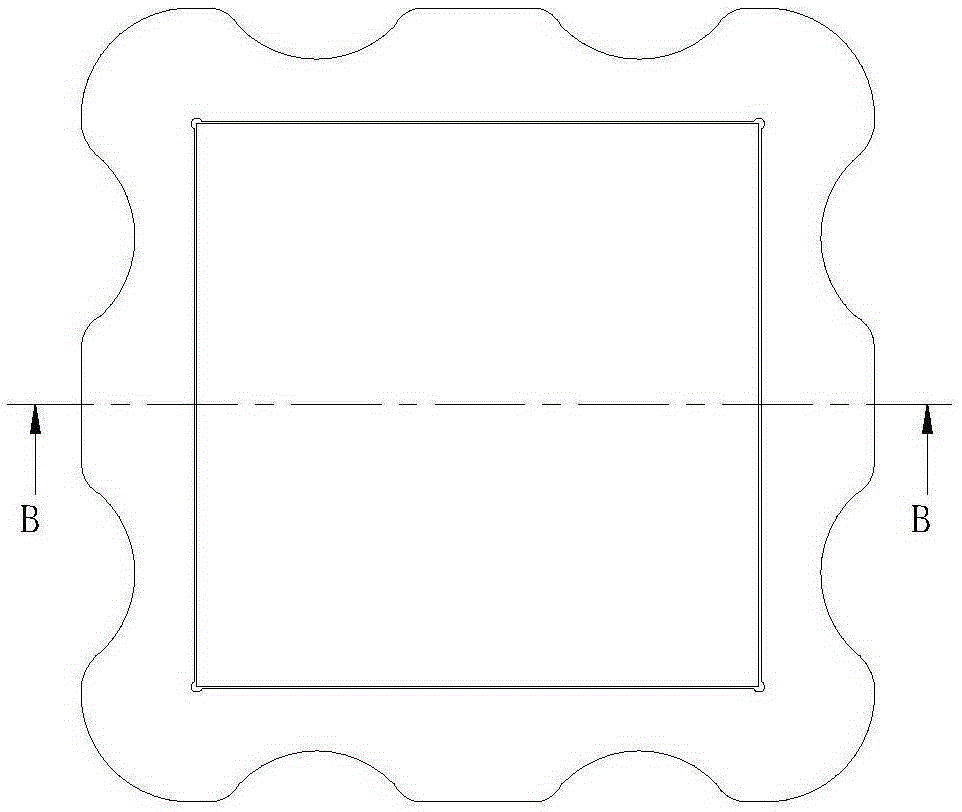

[0025] Such as image 3 and Figure 4 As shown, a support block for an independent liquid tank of a ship mainly includes a surrounding frame 21, and three non-metallic elastic supporting blocks 22, 23, 24 stacked sequentially in the surrounding frame from bottom to top. Adjust cushion blocks 25,26,27 and a slope adjustment cushion block 28.

[0026] The surrounding frame 21 is made of weldable cast steel or forged steel, and is welded on the hull. The height of the surrounding frame 21 is calculated according to the possible maximum hull deformation value and its corresponding relationship with the support block.

[0027] The non-metallic elastic support block is used to absorb the temperature transfer and support the weight of the independent liquid tank and the goods in the liquid tank above. In this example, three non-metallic elastic pads 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com