Novel Mn-4%Al-La-Sc alloy etchant solution

A technology for corrosion solution and alloy, which is applied in the field of new Mn-4%Al-La-Sc alloy corrosion solution, can solve the problems of increasing production cost and time consumption, and achieve cost saving, shortening time for metallographic sample preparation, metallographic Erosion simple and fast effect

Inactive Publication Date: 2015-12-30

周雪

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But this observation method is not only time-consuming, but also increases the production cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

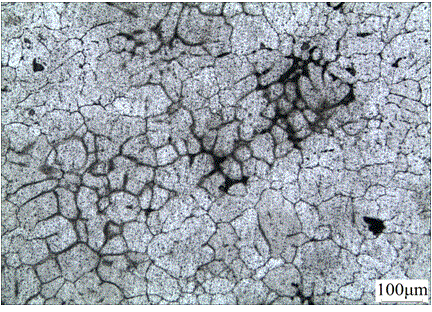

[0017] A new type of Mn-4%Al-La-Sc alloy corrosion solution, using mixed acid as raw material, prepared by conventional solution preparation method, adding 7.5% phosphoric acid and 4.5% hydrochloric acid and 9% hydrofluoric acid, and then stir evenly with a glass rod. The corrosion solution prepared by the above steps is used to corrode the Mn-4%Al-La-Sc alloy, the specific effect is shown in figure 1 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a novel Mn-4%Al-La-Sc alloy etchant solution. A preparation method of the etchant solution comprises the step of adding a certain amount of potassium hydroxide, hydrochloric acid and phosphoric acid to distilled water, wherein the compositions comprise, by mass, 9% of hydrofluoric acid, 4.5% of hydrochloric acid, 7.5% of phosphoric acid and the balance distilled water, and the adding sequence is that phosphoric acid is added in the first place, then hydrochloric acid is added, and finally hydrofluoric acid is added, and obtaining the etchant solution. By means of the etchant solution, metallographical corrosion of Mn-4%Al-La-Sc alloy can be made be as simple, fast and convenient as that of aluminum alloy, cost is saved, and the etchant solution is particularly applied to corrosion of the Mn-4%Al-La-Sc alloy.

Description

technical field [0001] The invention relates to a novel Mn-4%Al-La-Sc alloy corrosion solution, belonging to the technical field of corrosion solutions. Background technique [0002] The metallographic structure of Mn-4%Al-La-Sc alloy is difficult to corrode, and even if it is corroded, its structure is often displayed incompletely, so the metallographic phase is usually observed by anodic coating and polarized light. But this observation method is not only time-consuming, but also increases the production cost. Therefore, how to make the metallographic corrosion of Mn-4%Al-La-Sc alloy as simple and fast as that of aluminum alloy is a difficult problem to be solved. Contents of the invention [0003] The technical problem to be solved by the present invention is to provide a novel Mn-4%Al-La-Sc alloy corrosion solution, the metallographic structure of the Mn-4%Al-La-Sc alloy can be directly observed without anode coating Film processing and polarized light observation to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23F1/30G01N1/32

Inventor 周雪

Owner 周雪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com