Novel corrosive solution for 35Cr2MnSiC steel

A kind of corrosion solution, a new type of technology, applied in the field of corrosion solution, can solve the problems of time-consuming and high production cost, and achieve the effect of cost saving and metallographic corrosion simple and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] A new type of 35Cr2MnSiC steel corrosion solution, using mixed acid as raw material, was prepared by a conventional solution preparation method. In 79.1mL of distilled water, a volume of 5.8mL of nitric acid, 9.6mL of hydrochloric acid and 5.5mL of hydrofluoric acid were added successively, and then Stir well with a glass rod.

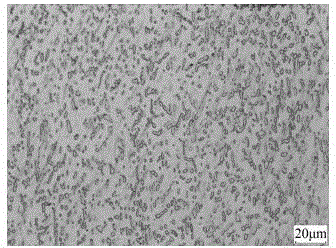

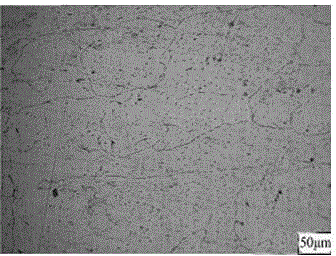

[0019] The corrosion solution prepared by the above steps is used to corrode 35Cr2MnSiC steel, the specific effect is shown in figure 1 and figure 2 , figure 2 Corrosion effect diagrams using other common corrosion solutions show that the corrosion solution of the present invention has a better effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com