Novel 38CrMg2NiA alloy corrosion solution

A corrosion solution and alloy technology, which is applied in the field of new 38CrMg2NiA alloy corrosion solution, can solve the problems of time-consuming and increased production costs, and achieve the effects of saving costs, shortening the time for metallographic sample preparation, and simple and fast metallographic corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] A new type of 38CrMg2NiA alloy corrosion solution, using mixed acid as raw material, prepared by conventional solution preparation method, adding 1.5mL of hydrochloric acid, 4.5mL of hydrofluoric acid and 20mL of alcohol in 84mL of distilled water, and then using glass Stick and stir well.

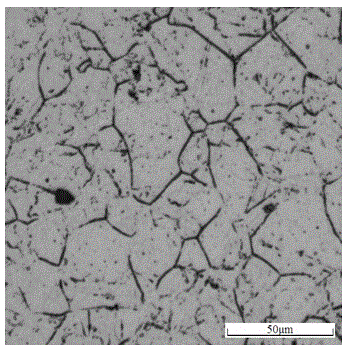

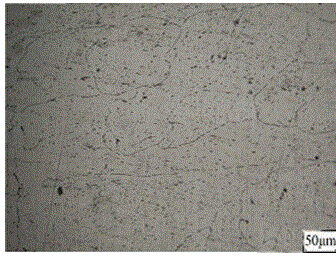

[0018] The corrosion solution prepared by the above steps is used to corrode the 38CrMg2NiA alloy, the specific effect is shown in figure 1 and figure 2 , figure 2 Corrosion effect diagrams using other common corrosion solutions show that the corrosion solution of the present invention has a better effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com