Multifunctional full-automatic washing machine inner cylinder structure and double-cylinder washing machine

A fully automatic washing machine and multi-functional technology, applied in the field of washing machines, can solve the problems of washing fabric deformation, time-consuming and energy-consuming, and the friction force of the inner drum of the washing machine is not perfect, so as to achieve the effect of increasing friction force and avoiding instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

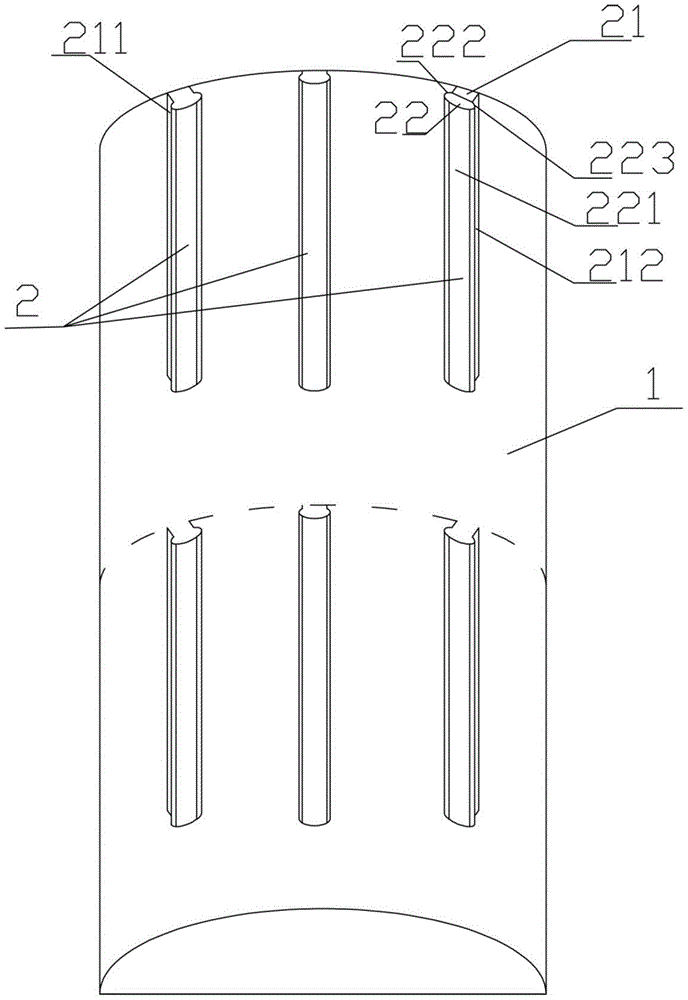

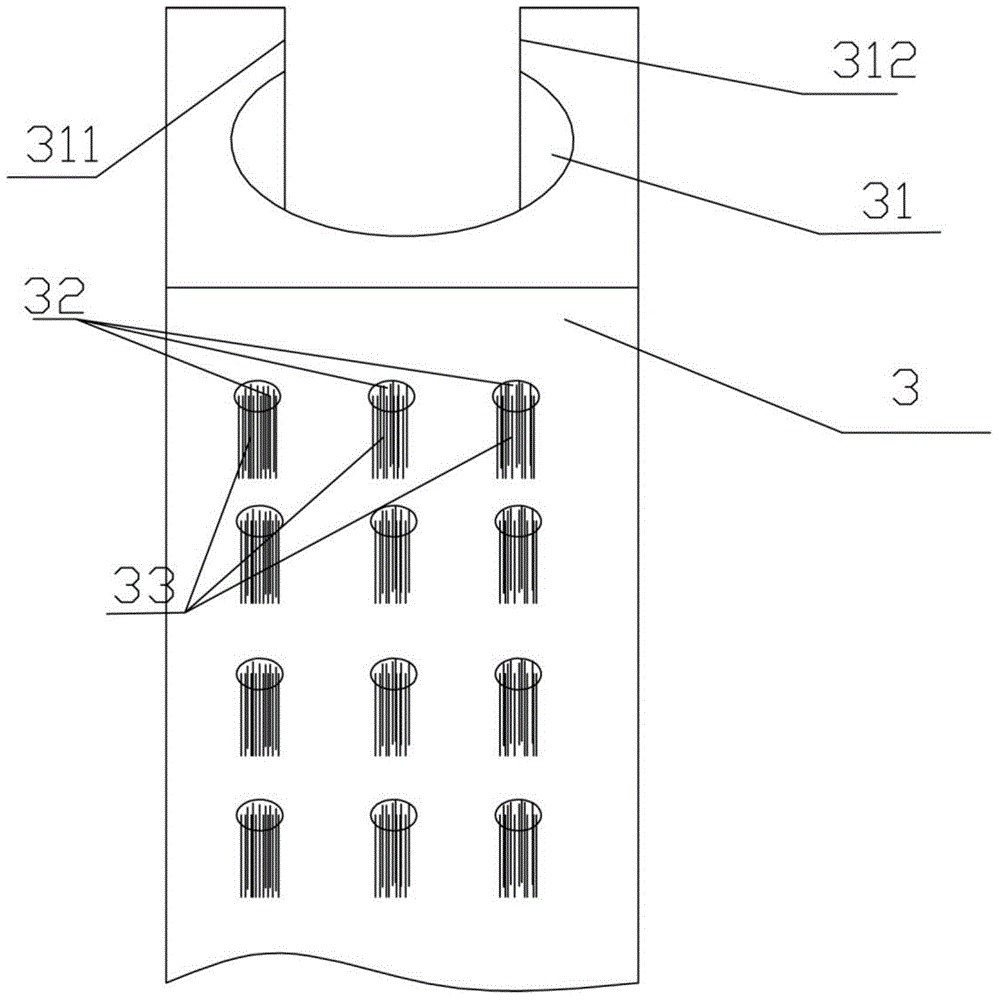

[0038] The inner cylinder mechanism of a multifunctional fully automatic washing machine of this embodiment can be used in a fully automatic single-tub washing machine, and can also be used in a double-tub washing machine in which washing and drying are separated. The multifunctional washing machine of this embodiment includes a washing machine body, such as Figure 1-Figure 2 As shown, the main body of the washing machine includes:

[0039] The inner barrel 1, the inner wall of the inner barrel 1 extends toward the direction of the central axis to form a raised strip 2; the raised strips are multiple, and the plurality of raised strips are parallel to each other and arranged vertically / horizontally on the inner barrel wall, which is preferred in this embodiment Two rows of convex strips are arranged on the inner wall of the washing machine body, so that even if the decontamination part is removed, the frictional force can be increased by using the breakpoints of the convex st...

Embodiment 2

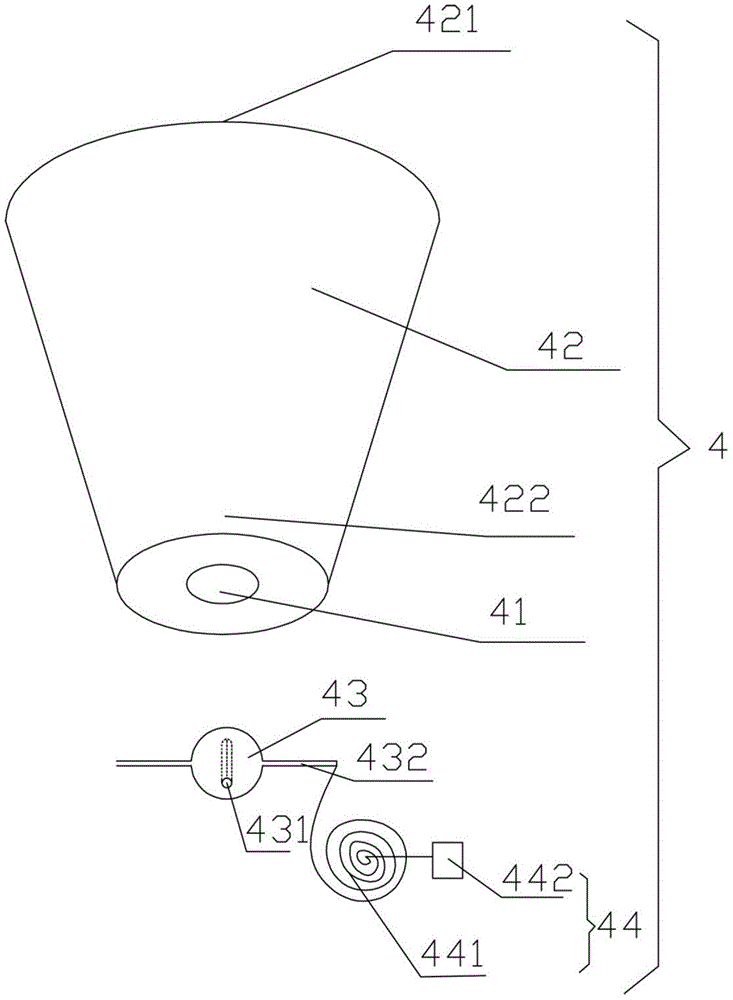

[0054] A kind of multifunctional double-tub washing machine of this embodiment, in addition to including the feature of the multifunctional washing machine described in Embodiment 1, also includes a drying bucket, and the drying bucket and the inner bucket are arranged side by side in the washing machine body, and the center position of the bottom of the drying bucket is A central bearing is provided, and the outer wall of the upper end of the spin-drying bucket is connected with the main body of the washing machine through a plurality of top bearings. The main body of the washing machine has a rectangular parallelepiped structure. A handle with a splint is added to the four corners of the drying barrel of the main body of the washing machine, and the top bearing is fixed on the main body of the washing machine with screws. When the bearing is worn or damaged, the bearing can be replaced. The top bearing can adopt 4 angular bearings, and the 4 angular bearings are evenly and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com