Casting cable trench after assembly of L-shaped precast concrete and construction method of casting cable trench

A technology of prefabricated concrete parts and cable trenches, which is applied in construction, artificial islands, water conservancy projects, etc., to achieve the effects of reducing maintenance costs, meeting waterproof requirements, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

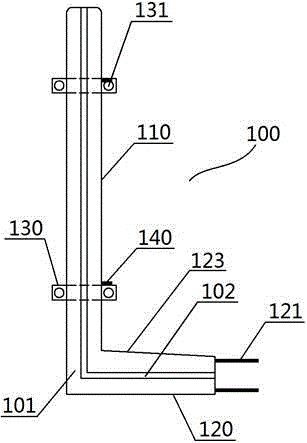

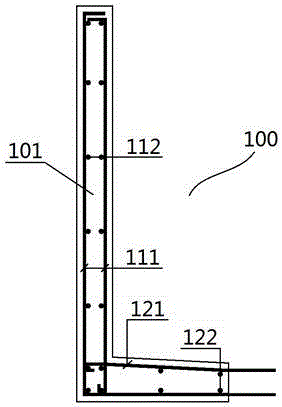

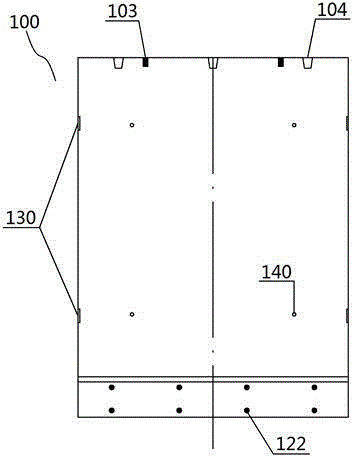

[0034] Such as Figure 1~6As shown, an L-shaped concrete prefabricated part is assembled and poured into a cable trench, including a plurality of L-shaped concrete prefabricated parts 100, and the L-shaped concrete prefabricated part 100 includes an L-shaped concrete body 101 composed of a side wall and a bottom plate. The side wall 110 of the concrete body 101 is arranged with side wall stress ribs 111 along the height direction and side wall distribution ribs 112 along the length direction, and the bottom plate 120 of the concrete body 101 is arranged with bottom plate stress ribs along the width direction 121 and the distribution rib 122 along the length of the bottom plate, one end of the bottom plate stress rib 121 is connected with the side wall stress ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com