Structure synchronous unloading device and construction method thereof

A technology of unloading device and structural column, which is applied in the direction of building construction, construction, and building material processing, etc., can solve problems such as low safety performance, short-term stress release, and impact on structural safety, and achieve high safety, convenient operation, and Avoid the effect of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

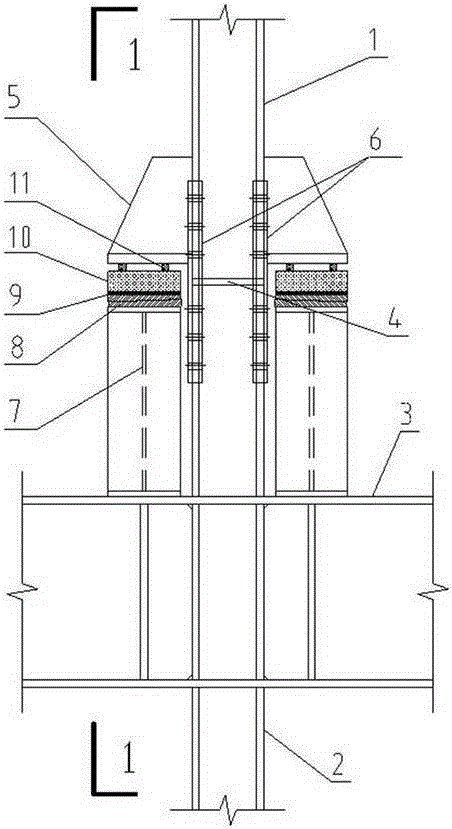

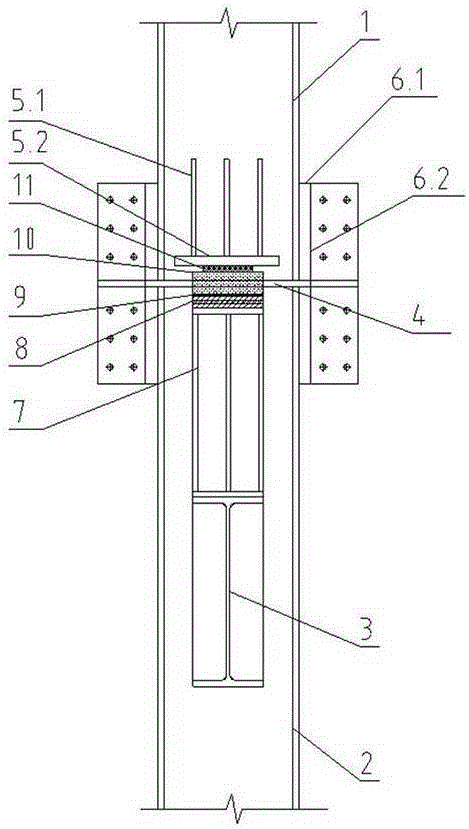

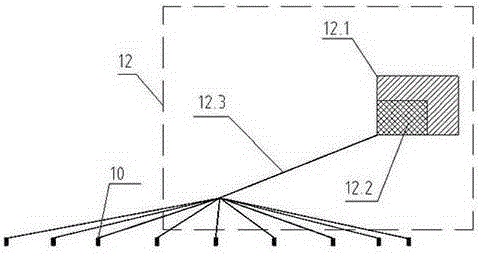

[0024] see Figure 1-3 , a structural synchronous unloading device, comprising an upper structural column 1, a lower structural column 2, a structural beam 3, a gap 4, a corbel 5, a temporary fixing device 6, a spacer 7, an inclined spacer 8, an adjustment spacer 9, a jack 10. U-shaped pad 11 and synchronous unloading control system 12, a gap 4 is provided between the upper structural column 1 and the lower structural column 2, and the size of the gap 4 is reserved between the upper structural column 1 and the lower structural column 2 It is the maximum vertical displacement of the lower end of the upper structural column 1 when the structure is unloaded. A corbel 5 is welded on the upper structural column 1. The corbel 5 is composed of a corbel vertical plate 5.1 and a corbel horizontal plate 5.2. The corbel The number of leg vertical plates 5.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com