Air film resistance reducing model based on wettability regulation and manufacturing method thereof

A technology of wettability and air film, which is applied in the fields of air film drag reduction and underwater drag reduction based on the regulation of solid surface wettability, can solve the problems of poor drag reduction effect and narrow flow rate range, and achieve processing difficulty and cost Low cost, simple and easy to operate, achieve continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment is an air film drag reduction model based on wettability control.

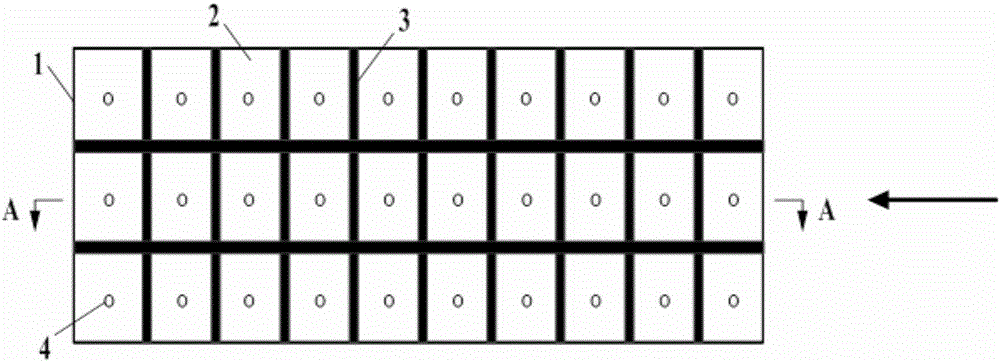

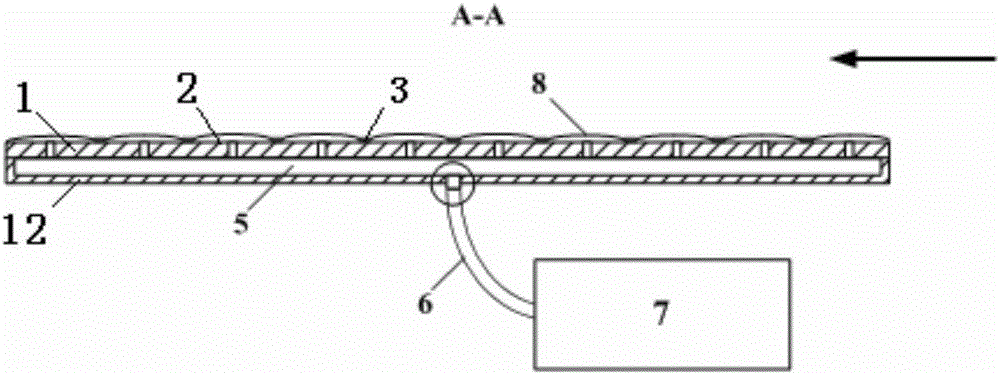

[0033] The air film drag reduction model is in the form of a flat plate, including an upper aluminum plate 1 and a lower aluminum plate 12, and an air chamber 5 is located between the upper aluminum plate and the lower aluminum plate. The intrinsic contact angle of the upper aluminum plate is 42°.

[0034] The upper surface of the upper aluminum plate 1 of the gas film drag reduction model is a drag reduction layer. The drag-reducing layer is composed of a plurality of hydrophilic regions 3 and a plurality of super-hydrophobic regions 2, and the hydrophilic regions and super-hydrophobic regions are arranged alternately, so that the drag-reducing layer is grid-like; the mesh The grid shape is quadrilateral, or hexagonal, or triangular, or circular; in this embodiment, the grid shape is quadrilateral.

[0035] Such as figure 1 shown. The intrinsic contact angle of each hydrophilic reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com